Cam Bearing Machining with CNC: Precision Fit, Installation, and Repair Guide

Introduction: Why Cam Bearings Matter in CNC Applications Cam bearings may seem minor, but in precision machining and engine performance, their importance is substantial. Over my years working with engine rebuilds and CNC machining, I’ve seen firsthand how the correct handling of cam bearings directly affects engine performance, durability, and efficiency. Even small inaccuracies in […]

STP File Compatibility with CAM Software: Best Tools Compared and Use Guide

Chapter 1: What is an STP File and Why It Matters in CNC An STP file (also called STEP file, with extensions .stp or .step) is a common 3D file format used to transfer data between different CAD/CAM software. It’s like a universal translator that ensures your design can be opened, viewed, and edited across multiple software […]

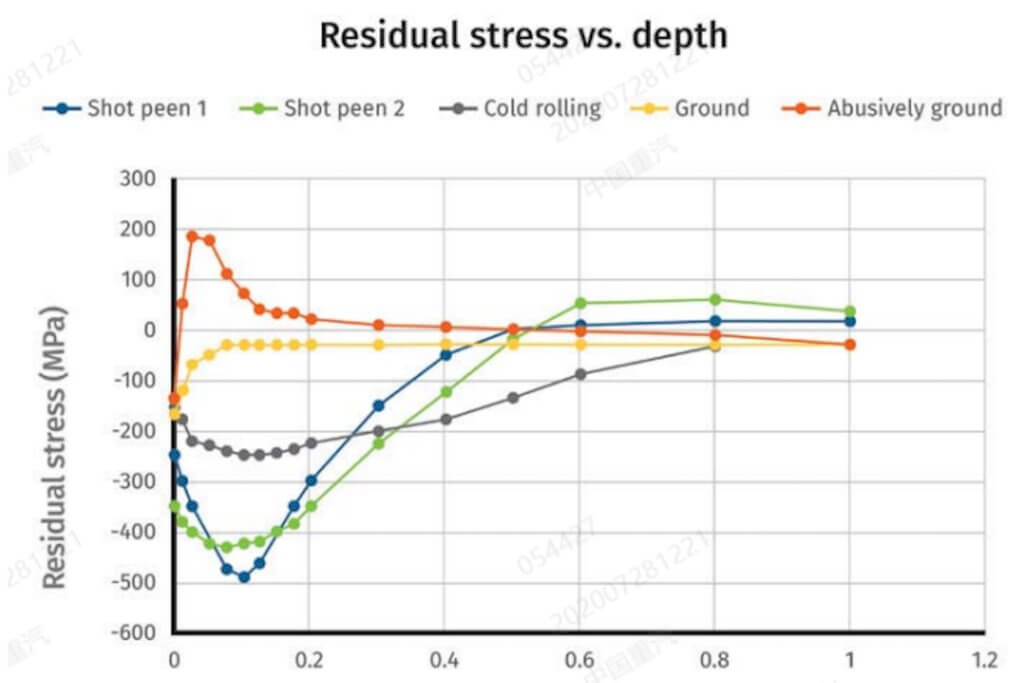

The Ultimate Guide to Stress Relieving for CNC Parts: When, Why, and How

Introduction Stress relieving has always been a point of fascination for me. I remember the first time I discovered how much of a difference it makes in CNC machined parts. I was visiting a friend’s small fabrication shop in the Midwest. We were working on a batch of steel components for a heavy machinery client. […]

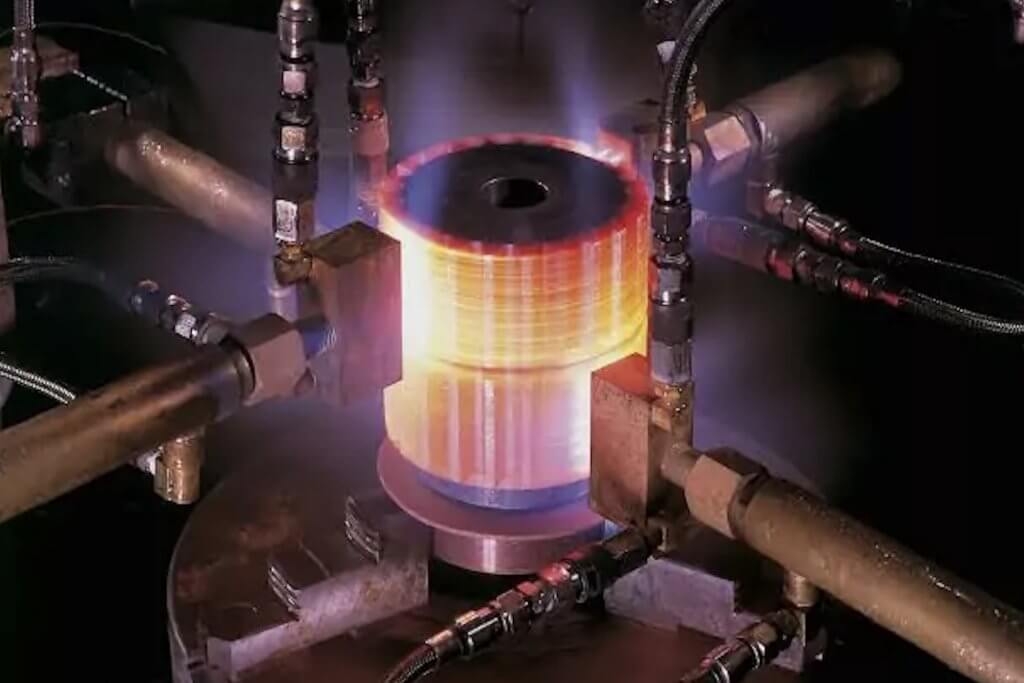

Annealed Metals in Manufacturing Explained: Softening, Stress Relief, and More

Chapter 1: What Does “Annealed” Mean in Manufacturing? If you’re involved in manufacturing or machining, you’ve probably come across the term “annealed” before. But if you’re new to the term, don’t worry. I’ll explain clearly, based on my own experiences and insights from the field. Annealing is a heat treatment process used primarily on metals to soften […]

Do You Need Tempering Before or After Machining? A Practical Guide for Engineers

Introduction Tempering is one of those topics that I’ve seen spark a lot of debate in custom manufacturing circles.I remember the first time I tried to machine a batch of hardened steel shafts without the right tempering strategy.I spent countless hours adjusting cutting parameters, swapping out tools, and trying to figure out why everything kept […]

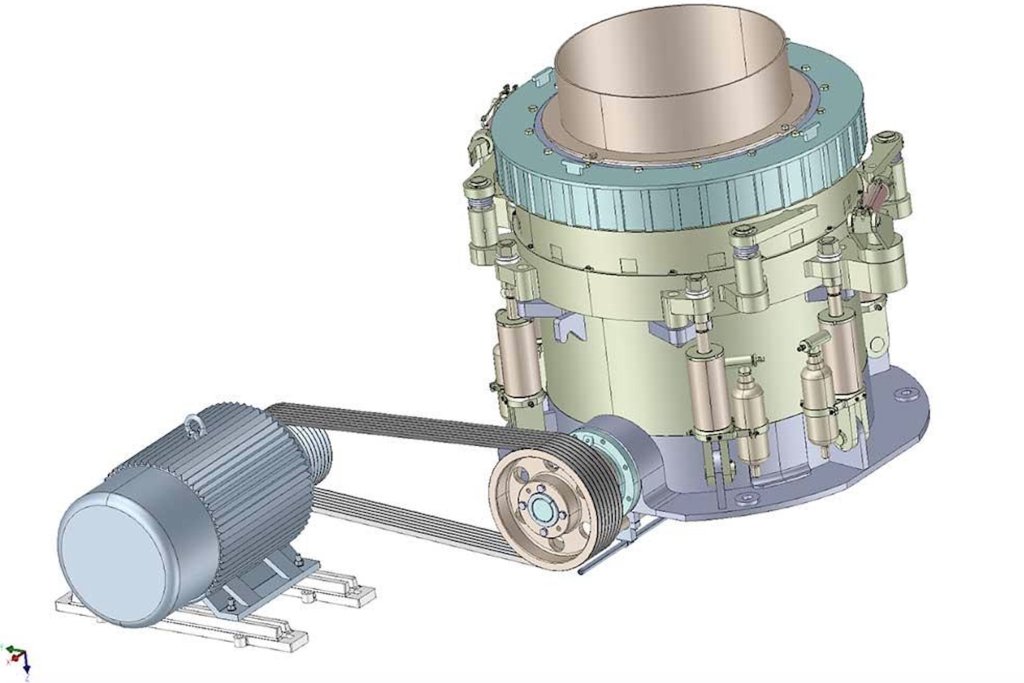

Custom Ball Bearing Manufacturing with CNC: Who Needs It and What’s Possible

Introduction: Why Custom Ball Bearings Are Gaining Popularity I’ve been fascinated by mechanical components ever since I first saw the inside of a small gearbox in college. Back then, I had no idea how important a ball bearing could be in keeping everything running smoothly. Over time, I learned that standard bearings often work just […]

How to Cut, Drill, and Modify ABS Pipe Using CNC Machines

Introduction ABS pipe is everywhere—from plumbing systems to DIY projects, from prototypes to structural parts in lightweight assemblies. But recently, I’ve noticed a growing trend: people want to take their ABS pipe applications further with precision customization, using CNC machines. I’ve done it myself, and it can be incredibly rewarding—when done right. This article is […]

How to Use a DXF File for CNC: From Design to Toolpath

Introduction I remember the first time I used a DXF file for my CNC router. I had a design in my head, scribbled it out on a piece of paper, then realized I needed a digital format to bring that idea to life. A friend said, “Use a DXF file. It’s the universal language for 2D shapes in CNC.”So […]

HDPE Machining Guide: Material Properties, Techniques and Applications

Introduction to HDPE and CNC Machining I remember the first time I encountered HDPE. I was working on a small project that required a lightweight, food-safe, and chemically resistant plastic. A friend mentioned HDPE (High-Density Polyethylene), and I was intrigued. I did some research and realized that HDPE offers a pretty interesting balance of strength, durability, and ease of machining. […]

Pinion Bearing Custom Manufacturing: From Concept to Finished Part

I. Introduction: What Is a Pinion Bearing and Why CNC Matters When I first started designing mechanical assemblies, I often heard people talk about a “pinion bearing.” It seemed like everyone I knew in automotive and industrial sectors used this phrase. But I realized that many folks, including me back then, didn’t fully understand the […]

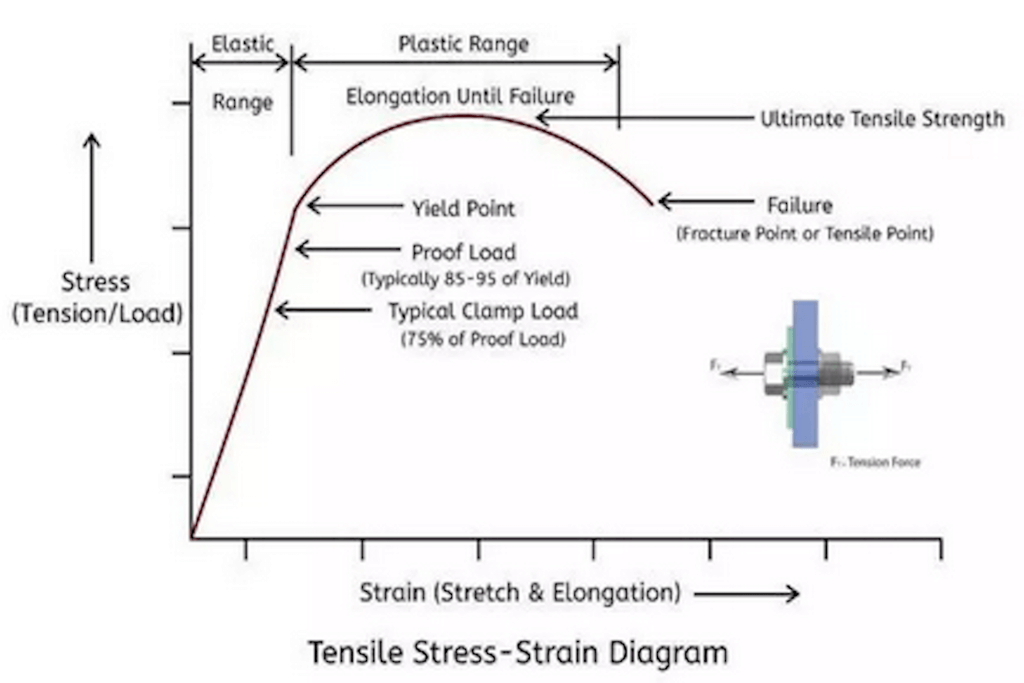

Yield Strength vs Tensile Strength: CNC Material Choice and Process Optimization

I. Introduction 1. Definition of Yield Strength and Tensile Strength I remember the first time I encountered the terms yield strength and tensile strength in my early machining projects. Yield strength refers to the stress level at which a material begins to deform permanently. When stress is lower than the yield point, the material returns to its original shape […]

Complete Guide to Metal Brake and CNC Machining: Techniques, Tools, and Applications

I. Introduction Metal brake is essential tool in modern manufacturing, especially when combined with CNC technology. These machines precisely bend and shape metal sheets, playing a crucial role in industries from automotive to aerospace. CNC machining enhances a metal brake’s accuracy, repeatability, and efficiency, making complex projects simpler and faster. I’ve worked closely with metal […]