Custom Worm Gears Manufacturing with CNC Machining Expertise

Introduction to Worm Gears and CNC Worm gears are a fascinating and essential component of many modern machines. They might look simple at first glance—a helical gear engaging with a threaded worm shaft—but their functionality is anything but basic. These gears are prized for their ability to achieve high reduction ratios in a single stage, […]

U Bolts: Key Factors to Consider When Ordering or Designing with CNC

Why CNC Machining Matters for U Bolts When you first start working with U bolts, it may seem like a basic and straightforward task. After all, how hard can it be to create a simple U-shaped bolt? But trust me, after years of experience across industries like automotive, aerospace, and construction, I can confidently say […]

Comprehensive Guide to High Carbon Steel Properties and CNC Machining Solutions

Introduction When it comes to advanced manufacturing and precision machining, high carbon steel stands out as a critical material in industries such as automotive, aerospace, toolmaking, and industrial machinery. Its remarkable hardness, strength, and wear resistance make it an indispensable choice for applications requiring durability and long service life. However, its machinability presents unique challenges, especially when […]

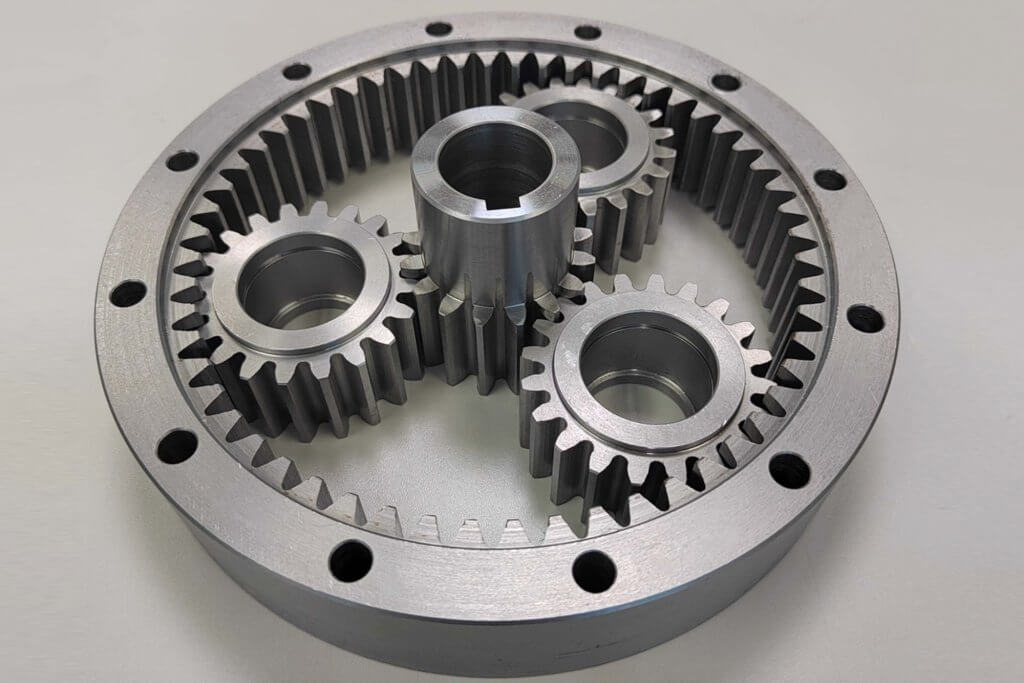

Master CNC Machining for Planetary Gear: Design, Tools, and Applications

What Is a Planetary Gear and Why Is It Important? When discussing advanced mechanical systems, few designs are as efficient and versatile as the planetary gear. Known for its compact structure and exceptional torque capacity, a planetary gear is a vital component in various high-performance machines. From automobiles to aerospace systems, this gear type ensures reliable […]

Master CNC Machining with ABS Plastic Sheet: Tools, Tips, and Techniques

Introduction: Mastering CNC Machining with ABS Plastic Sheet When it comes to CNC machining, the choice of material can make or break a project. ABS plastic sheet is one of the most versatile and commonly used materials in industries like automotive, electronics, and prototyping. Its lightweight, durable, and machinable properties make it a favorite among professionals and […]

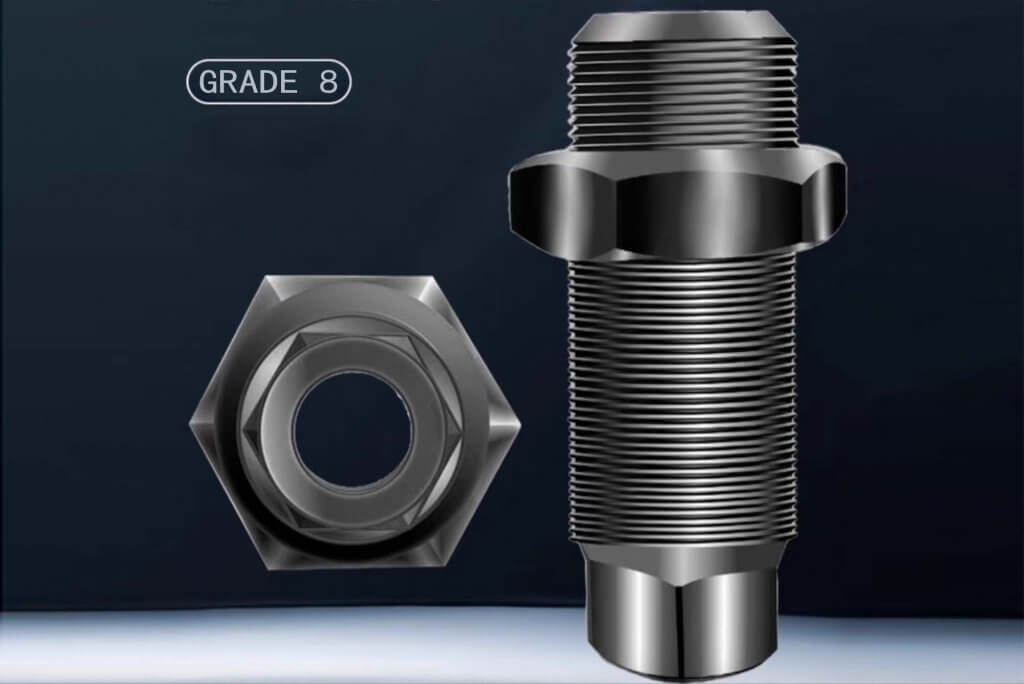

Custom Machining Grade 8 Bolts: Strength, Precision, and Durability

Introduction In the world of high-performance fasteners, Grade 8 bolts are a class apart. These bolts, made from medium-carbon alloy steel, are specially engineered to endure extreme stress, high torque, and challenging environmental conditions. With their exceptional tensile strength of 150,000 PSI, they are the go-to choice for industries that demand reliability, precision, and durability. When I first […]

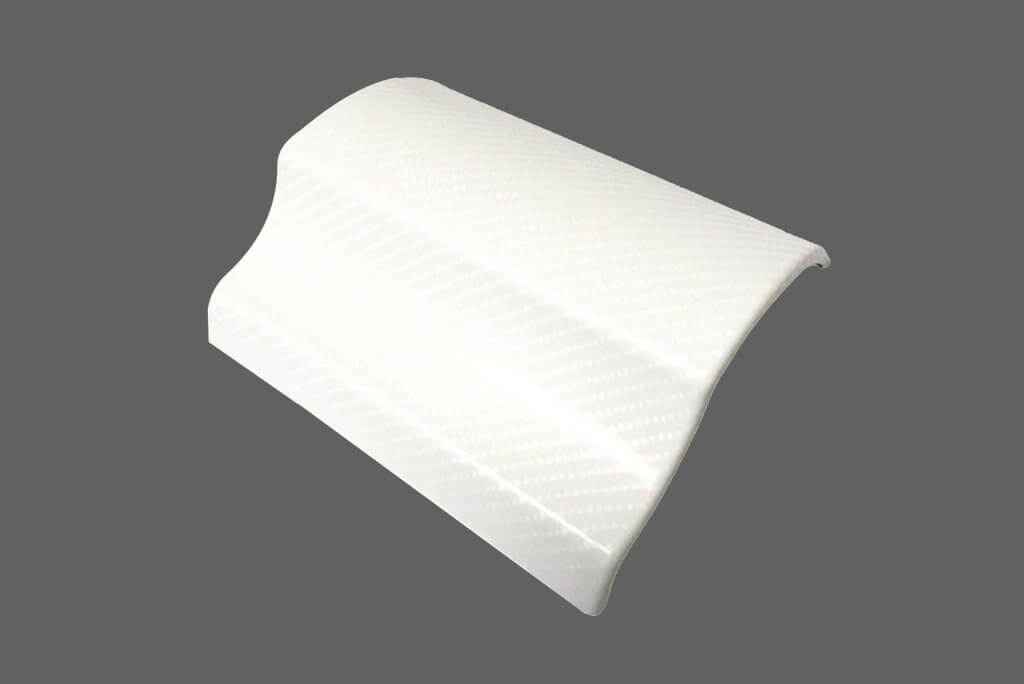

What Is White Carbon Fiber? Applications and CNC Processing Explained

Introduction White carbon fiber is a fascinating material that combines the strength and lightweight properties of traditional black carbon fiber with a striking aesthetic appeal. Unlike the typical black or gray tones associated with carbon fiber, white carbon fiber offers a clean, modern appearance, making it a preferred choice for industries prioritizing both performance and design. […]

Maximizing Strength and Durability: Custom CNC Anchor Bolts for Structural Applications

Introduction Anchor bolts are an integral part of modern construction, serving as the foundation for structures ranging from residential buildings to massive infrastructure projects like bridges, towers, and offshore platforms. Whether you’re working on a building project, machinery installation, or industrial construction, choosing the right anchor bolts is critical for ensuring that your structure remains secure and […]

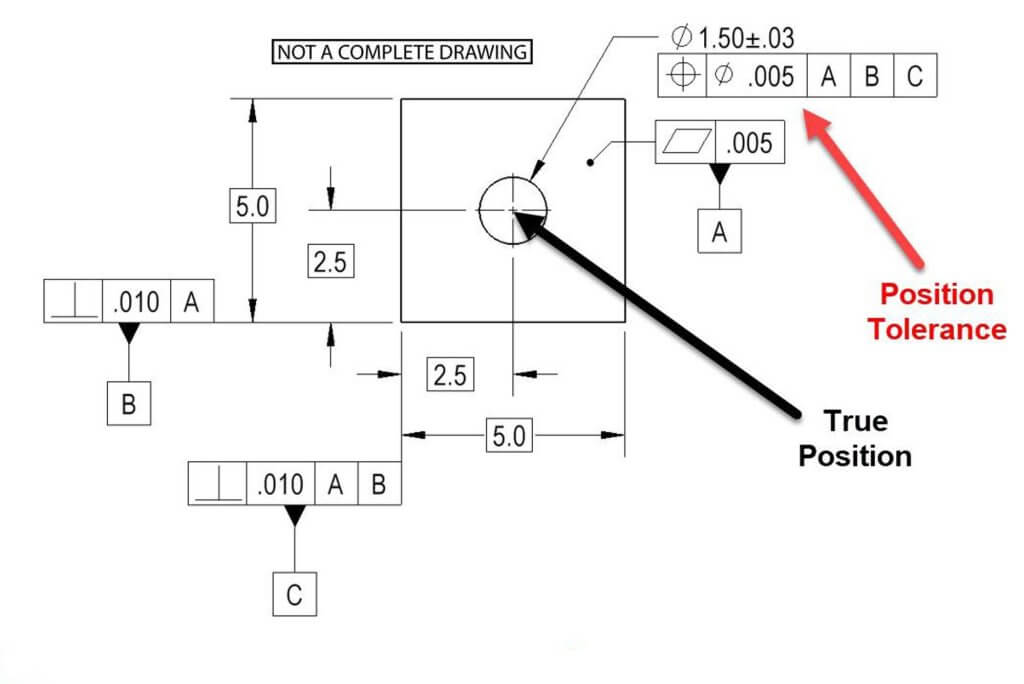

Mastering GD&T Symbols for CNC Machining: A Practical Guide for Engineers

Introduction Overview of GD&T Symbols and CNC Geometric Dimensioning and Tolerancing (GD&T) is a language used to define the geometry and tolerance of mechanical components. When working with CNC (Computer Numerical Control) machining, GD&T ensures that the parts being manufactured are within the desired tolerances and meet the required specifications for performance.In custom machining, where unique designs and […]

About Pilot Bearing: Design Customizing Tips, CNC Machining Insights, and Sourcing Guide

Introduction A pilot bearing may seem like a small component, but it plays a critical role in the smooth operation of clutch systems, transmission assemblies, and industrial equipment. Its purpose goes beyond merely supporting the input shaft; it ensures proper alignment and reduces wear on connected components, which is vital for long-term reliability. As someone […]

How to Procure and Machine Custom Helical Gear: A Step-by-Step Guide for Manufacturers

Introduction Custom helical gear is integral components in machinery where precision, performance, and durability are non-negotiable. From personal experience, I’ve found that whether you’re designing a state-of-the-art automotive transmission, an advanced aerospace application, or intricate industrial equipment, understanding both the procurement and custom machining processes of custom Helical Gear is crucial for success. Manufacturers often […]

Optimize Your Machining: Expert Tips for Selecting the Right Grinding Disc

Grinding discs are an essential tool in machining, construction, automotive, and other industries. The right choice of grinding disc can dramatically improve efficiency, reduce costs, and ensure a high-quality finish on your projects. In the realm of custom machining, selecting the perfect grinding disc becomes even more crucial to achieve precise and tailored results. Whether […]