Lag Bolts Specifications and Materials: Choosing or Machining the Right Lag Bolt for Your Project

Introduction Overview of Lag Bolts: What They Are and Common Applications Lag bolts are among the most reliable fasteners used in construction, furniture manufacturing, heavy machinery assembly, and many other industrial applications. These large, heavy-duty screws feature a hexagonal head and coarse threads, which make them ideal for securing timber, metal, and even concrete structures. […]

Linear Bearing Guide: Types, Applications, and Selection Tips for CNC Systems

Introduction If you’ve worked with CNC machines, you know how critical precision and smooth motion are to achieving consistent results. At the heart of this precision lies an often-overlooked component: the linear bearing. A linear bearing enables smooth, low-friction motion along a linear axis, making it indispensable in CNC systems, industrial automation, and other high-precision […]

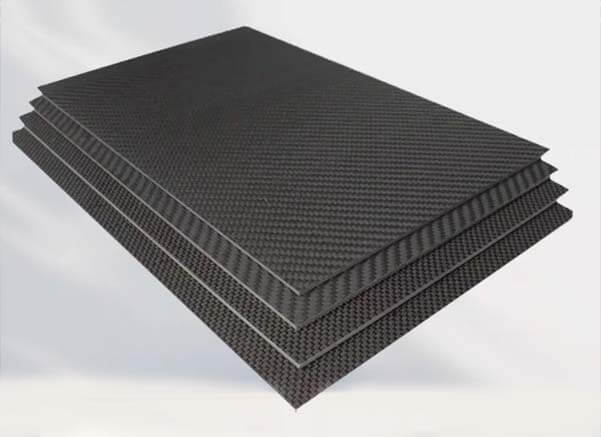

Carbon Fiber Sheets in CNC Machining: Applications, Techniques, and Cost Insights

Introduction When it comes to lightweight and high-strength materials, carbon fiber sheets are among the top choices for industries like aerospace, automotive, and electronics. Their unique properties, such as rigidity, corrosion resistance, and low weight, make them ideal for applications where performance and efficiency are critical. However, successfully working with carbon fiber sheets requires precision, […]

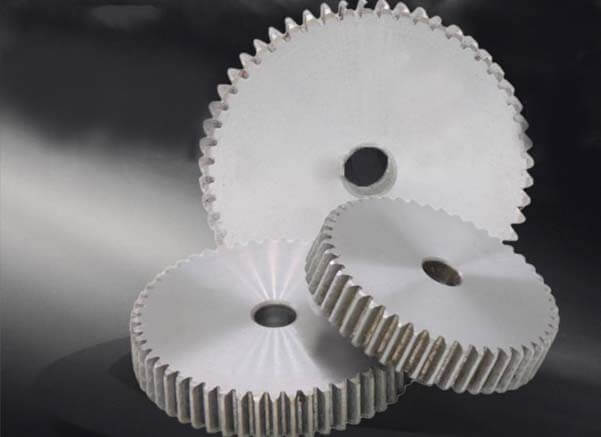

Straight Cut Gears Explained: What They Are and Why They Matter in CNC Machining

Introduction If you’ve worked with high-performance machinery or explored CNC machining, you’ve likely come across the term straight cut gears. These gears are renowned for their efficiency in transferring power and their use in precision-driven industries like automotive, aerospace, and industrial equipment. Straight cut gears are also a popular choice in custom machining, where specific […]

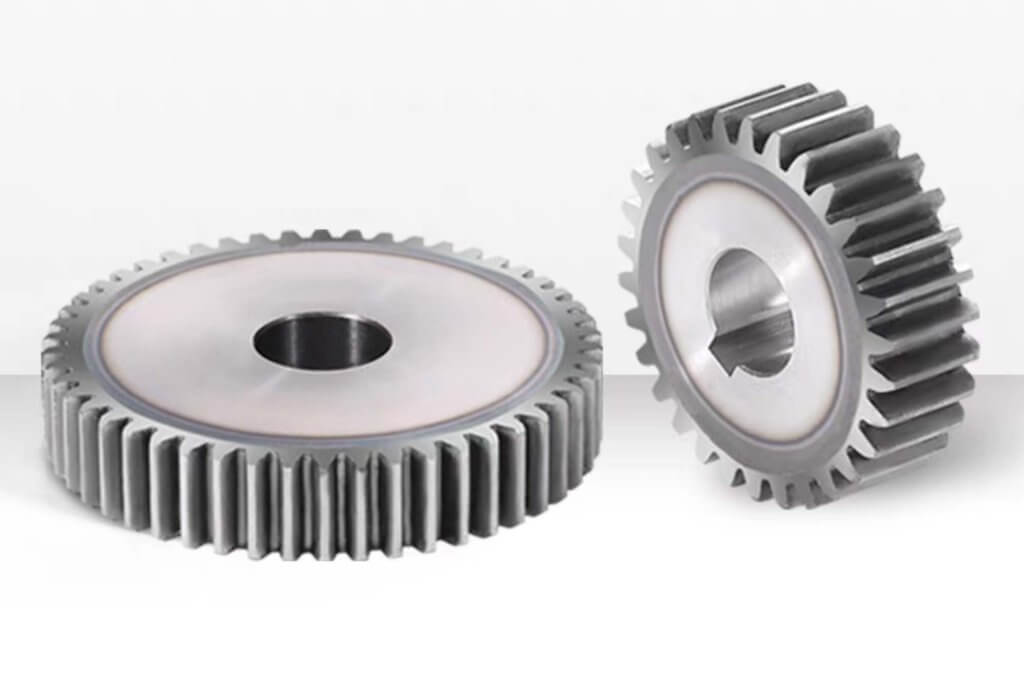

How to Choose a Grinding Wheel for CNC: Tips to Avoid Common Pitfalls

Introduction: Grinding Wheel and CNC Machining If you’ve ever worked with CNC or custom machining, you already know how important the right tools are to achieving precision and efficiency. Among these tools, the grinding wheel plays a pivotal role, especially when dealing with materials that require high accuracy or a polished finish. Selecting the wrong […]

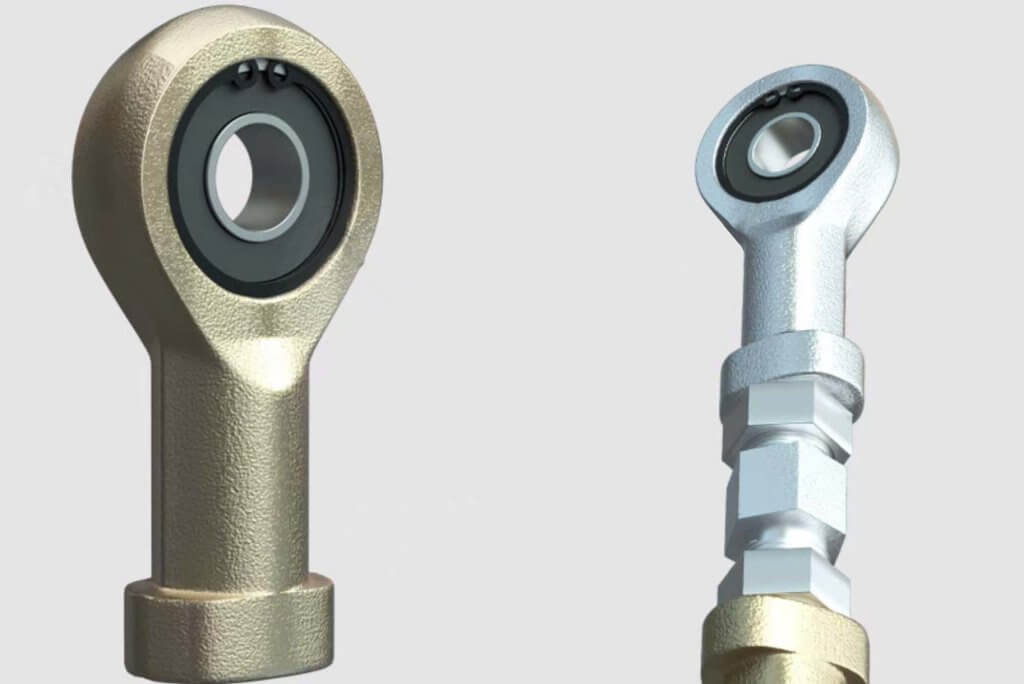

Journal Bearing Machining: Mastering Techniques for Precision and Performance

I. Introduction Journal bearing, a staple in many industries, serve as a critical component for supporting rotating machinery. Whether you’re working with high-speed turbines in energy plants or automotive crankshafts, journal bearing is essential for reducing friction, bearing heavy loads, and ensuring operational efficiency. But achieving their peak performance isn’t just about the design; it’s […]

Spur Gear Machining: A Complete Guide to Design and Manufacturing

Introduction: The Role of Spur Gears in Modern Industry I’ve worked with mechanical systems for several years, and along the way, I’ve realized how crucial a spur gear can be. A spur gear might look simple—it’s a wheel with straight teeth that mesh with another gear—but it’s often the heart of countless machines. When I […]

Exploring Rod Bearing: Customization, Machining, and Supply Chain Dynamics

Introduction: What is a Rod Bearing? When I first learned about rod bearing, I was surprised by how such a seemingly small and simple component plays a pivotal role in engine performance. A rod bearing is more than just a connector—it is the heart of an engine’s rotating assembly, ensuring smooth motion and reducing friction […]

Carbon Fiber Phone Case Uncovered: From Material Science to Cutting-Edge Machining

Why Carbon Fiber for Phone Cases? When you hear about a carbon fiber phone case, what’s your first thought? For many, it’s the image of a sleek, lightweight, and durable cover that combines style with performance. But Carbon Fiber Phone Case isn’t just about aesthetics—they represent a fascinating intersection of material science and advanced manufacturing […]

Everything About Types of Gears: Straight, Helical, Bevel, and More

Introduction When I first started learning about types of gears, I thought they all looked alike: just round devices with teeth that mesh together. But as I dug deeper, I realized that gears come in a wide variety of shapes and configurations—each designed to handle specific loads, speeds, and torque requirements. From the simple straight […]

Exploring Bevel Gear Machining: Design, Precision, and Innovation

Introduction I remember the first time I noticed a bevel gear in action. It was part of a complex gear train inside a small industrial machine I was helping to maintain. At the time, I had only read about bevel gear concepts in textbooks. Seeing one up close made me realize how integral these gears […]

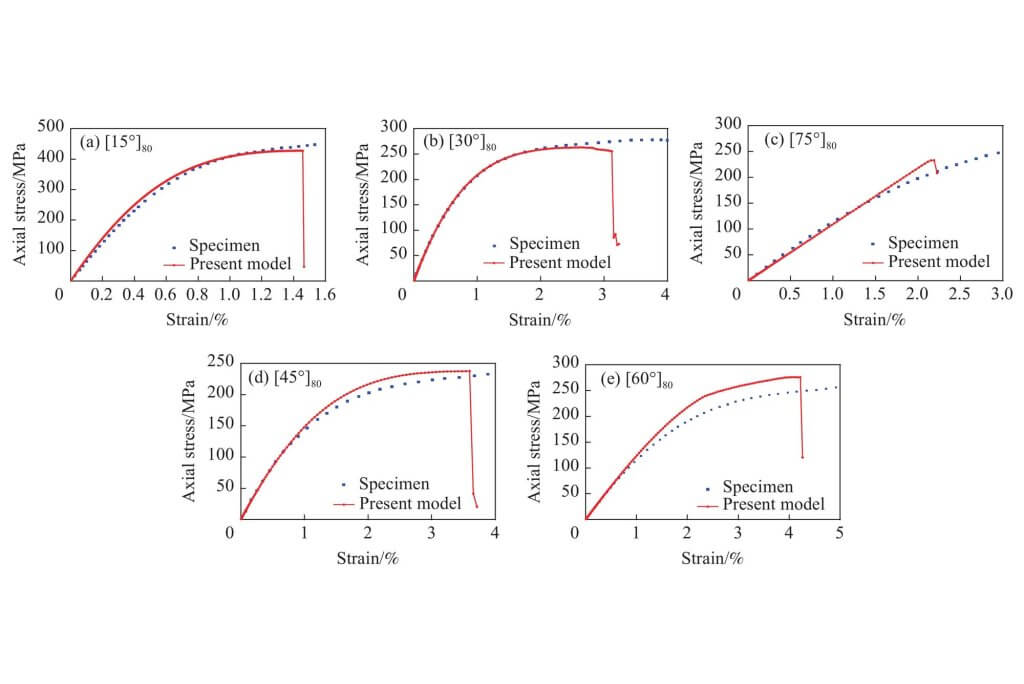

Decoding Carbon Fiber Strain in Advanced Machining Applications

Introduction: The Unique Properties and Applications of Carbon Fiber I’ve always been fascinated by how materials behave under stress. Carbon fiber, in particular, has this almost legendary status in aerospace, automotive racing, and even sporting goods. When I first heard about carbon fiber strain, I realized it wasn’t just a random scientific term—it captured the […]