Ceramic Coating and Machining: Unlocking Advanced Manufacturing Applications

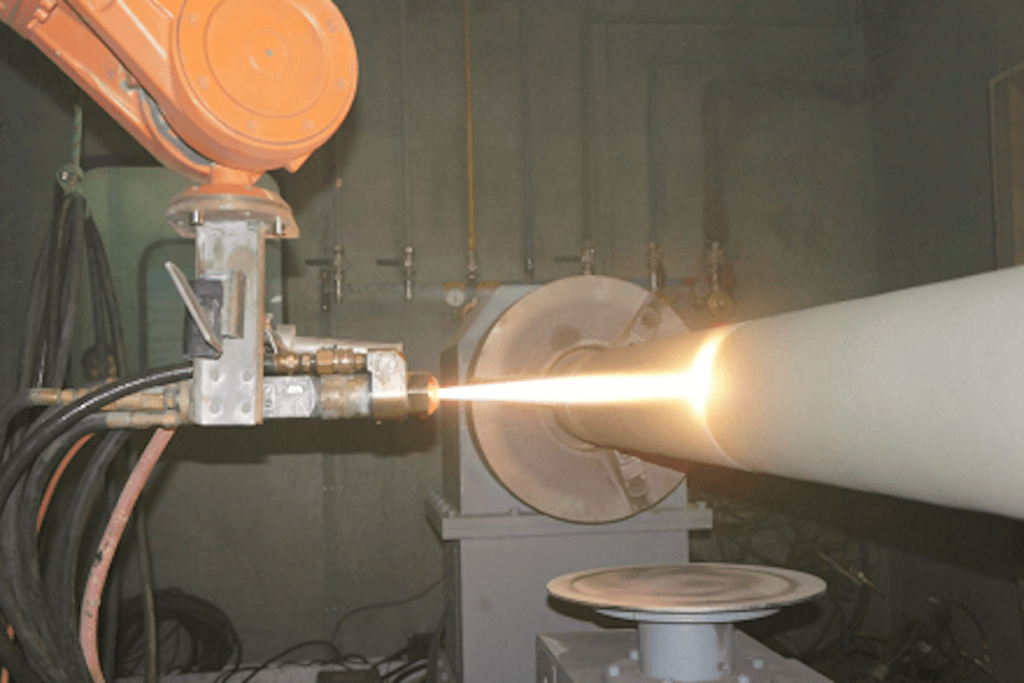

Introduction I’ve been fascinated by the way ceramic coating can radically transform the performance of machined parts. Ceramic coating, as a concept, goes well beyond the automotive finishes many of us see in car detailing shops. In high-precision manufacturing, ceramic coating can enhance temperature resistance, reduce friction, and extend the lifespan of components subject to […]

Aluminum Angle Uncovered: Tips for Machining, Industry Application, and Beyond

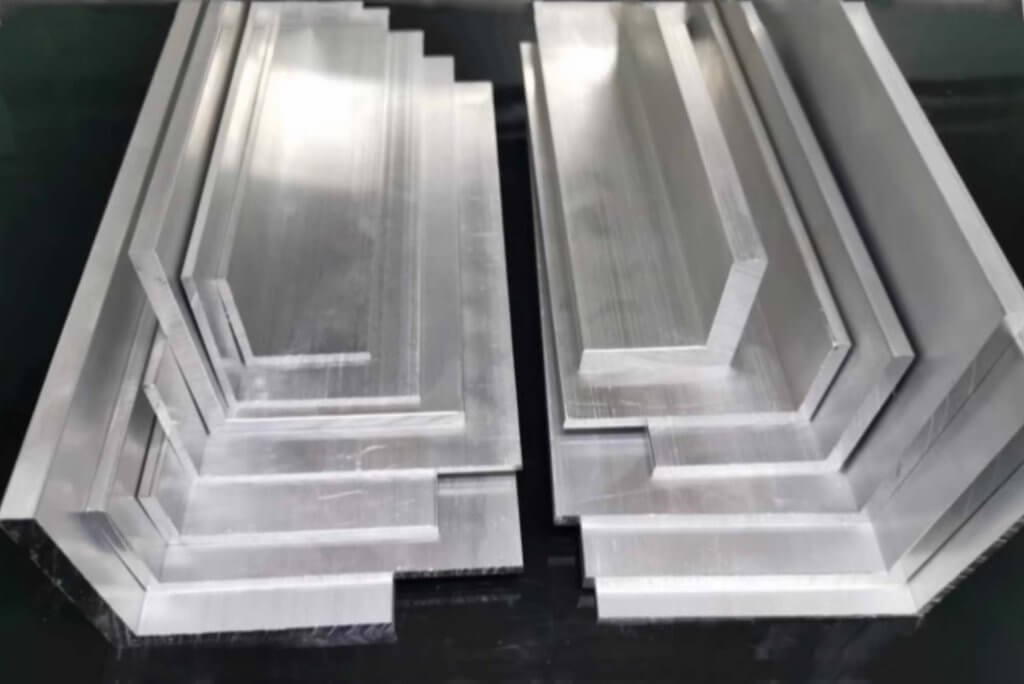

Introduction: Unique Advantages of Aluminum Angle I’ve always been fascinated by the lightweight properties of aluminum angle and the sheer range of possibilities it opens up for different industries. Aluminum angle has repeatedly proven its versatility in construction, automotive applications, and various machining scenarios. Whenever I think about aluminum angle, I’m reminded of the first […]

International Metal Processing Standards and CNC Compatibility Guide

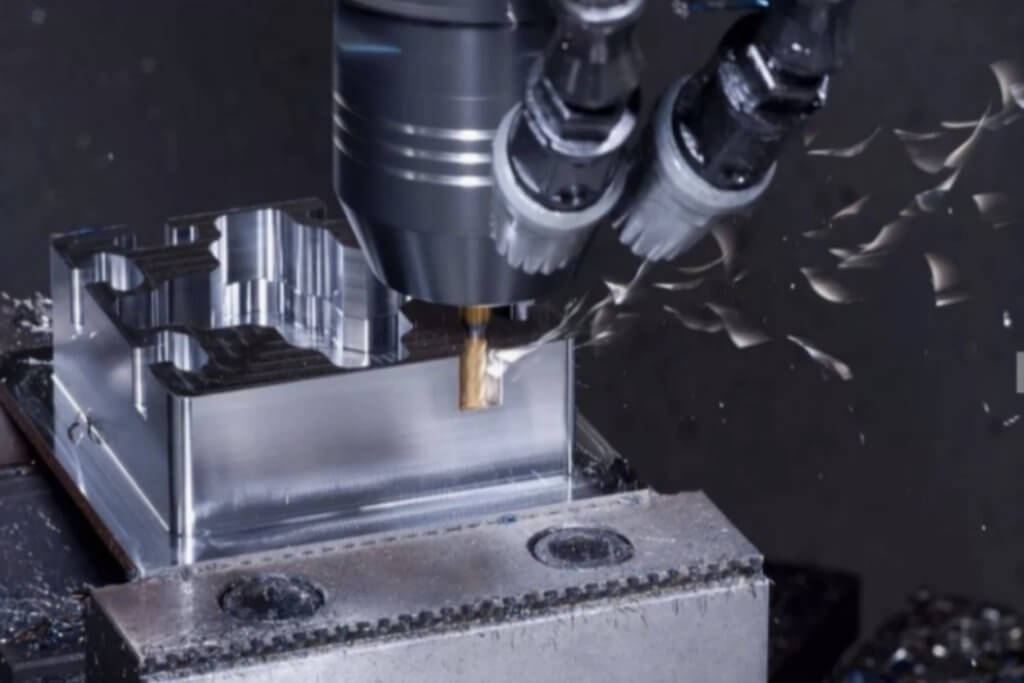

Introduction As a mechanical engineer specializing in CNC machining, I’ve often faced challenges related to adapting metalworking processes to different international standards. Navigating the complex web of global standards can be daunting, but it’s essential for ensuring product quality, compliance, and customer satisfaction, especially when catering to diverse international markets. This guide is designed to […]

CNC Machining Common Metal Performance Comparison Chart

CNC machining has become an essential process in modern manufacturing, where precision and efficiency are key. Whether you’re designing aerospace components, automotive parts, or medical devices, selecting the right metal can make all the difference. This is where the “CNC Machining Common Metal Performance Comparison Chart” comes into play. As someone who has spent years […]

Creative Lathe Projects: Transform Ideas into Real Creations

I. Introduction Lathes are one of the most versatile tools in any workshop. Whether you’re crafting a wooden bowl, turning a precision metal part, or experimenting with CNC designs, lathe projects allow you to bring your ideas to life. Over the years, I’ve explored various lathe projects and discovered that they’re not only practical but […]

Harbor Freight Lathe: A Beginner’s Guide to Machining Basics

Introduction: Why Choose a Harbor Freight Lathe? I remember the first time I wanted to try my hand at metalworking. I didn’t have a huge budget, and I needed a lathe that was affordable but still capable of real machining. That’s when I discovered the Harbor Freight lathe lineup. These lathes are known for their […]

In-Depth Analysis of Nylon 66: Machining Properties and Applications

Introduction I want to share my personal experiences and observations regarding the remarkable material called Nylon 66. I’ve seen plenty of engineering plastics throughout my career, and each has its own characteristics. But Nylon 66 stands out due to its balance of strength, flexibility, and heat resistance. When I first encountered Nylon 66 as a […]

Unlocking the Potential of Bronze Bushings with CNC Machining

I. Introduction Bronze bushings are an indispensable component in the world of mechanical engineering. They provide critical support for rotating parts, reduce friction, and enhance the efficiency of countless machines. With the advent of CNC machining, the possibilities for customizing and improving the performance of bronze bushings have expanded significantly. From my experience, I’ve seen […]

Creative CNC Projects: Ideas, Techniques, and Profitable Applications

Chapter 1: Introduction What Are CNC Projects? CNC projects involve using Computer Numerical Control (CNC) machines to create physical objects. These machines operate based on precise digital instructions to cut, carve, or mill various materials such as wood, metal, acrylic, and plastics. CNC technology eliminates human error, providing unparalleled accuracy and efficiency in manufacturing processes. […]

CNC Laser Applications That Are Reshaping Industries Today

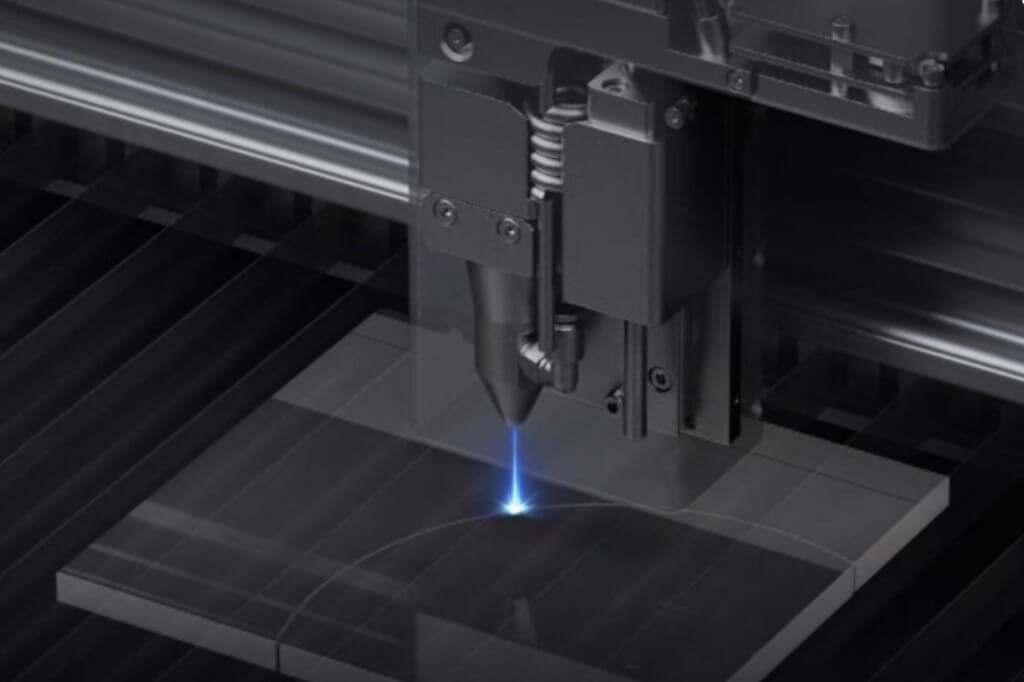

I’ve spent a significant amount of time looking into how different manufacturing technologies evolve, and one technology that keeps grabbing my attention is CNC laser. When people talk about CNC laser solutions, they’re often referring to cutting-edge systems that combine the precision of computer numerical control (CNC) with the power of laser beams. But what […]

Brass Tacks Demystified: A Deep Dive into Machining Techniques and Innovations

I’ve spent a fair bit of time learning about different metal fasteners, and brass tacks are one of those intriguing items that bridge function and design. When you look at a finished piece of furniture or a detailed decorative panel, you might notice small round-headed tacks that seem to enhance the overall look. Those are […]

Billet Aluminum Unlocked: Expert Machining Techniques and Real-World Applications

Introduction: Why Billet Aluminum Matters in Machining I’ve worked with various metals and alloys, but billet aluminum has always stood out for its potential and versatility. Billet aluminum refers to aluminum stock—often in the form of a solid block or bar—that’s machined into complex shapes. It’s different from cast or extruded aluminum because it starts […]