6061 Aluminum in Machining: Your Guide to Precision and Performance

Introduction: The Perfect Pairing of 6061 Aluminum and CNC I’ve always been fascinated by how everyday objects—like car parts or phone casings—start as raw materials and end up as precision-engineered pieces. That’s where 6061 aluminum comes in. It’s a material I’ve seen transform under the hum of a CNC machine, and I’m excited to share […]

Screw Challenges Solved: Your CNC Troubleshooting Guide

Introduction: Why Screw Challenges Matter in CNC Screws are everywhere. From the chair I’m sitting on to the car I drove this morning, screws hold our world together. But when it comes to CNC machining, screws aren’t just tiny heroes—they can be a real headache. I’ve spent years tinkering with CNC machines, and I can […]

A36 Steel: Best Practices for CNC Machining and Cost Control

Introduction Overview of A36 Steel: Material Properties, Composition, and Applications A36 steel has become one of the most widely used materials in the world, and it’s the go-to choice for various industries ranging from construction to machinery to automotive manufacturing. In my experience, it’s a dependable and affordable material that offers excellent machinability and weldability, […]

The Ultimate Guide to Anodized Aluminum Machining: Properties, Processes, and Applications

Chapter 1: Introduction to Anodized Aluminum Anodized aluminum is not just aluminum with a colorful finish. It is aluminum that has been treated through an electrochemical process to form a protective oxide layer. In my experience with Custom Machining, I found that this process not only enhances the material’s durability but also allows for a high […]

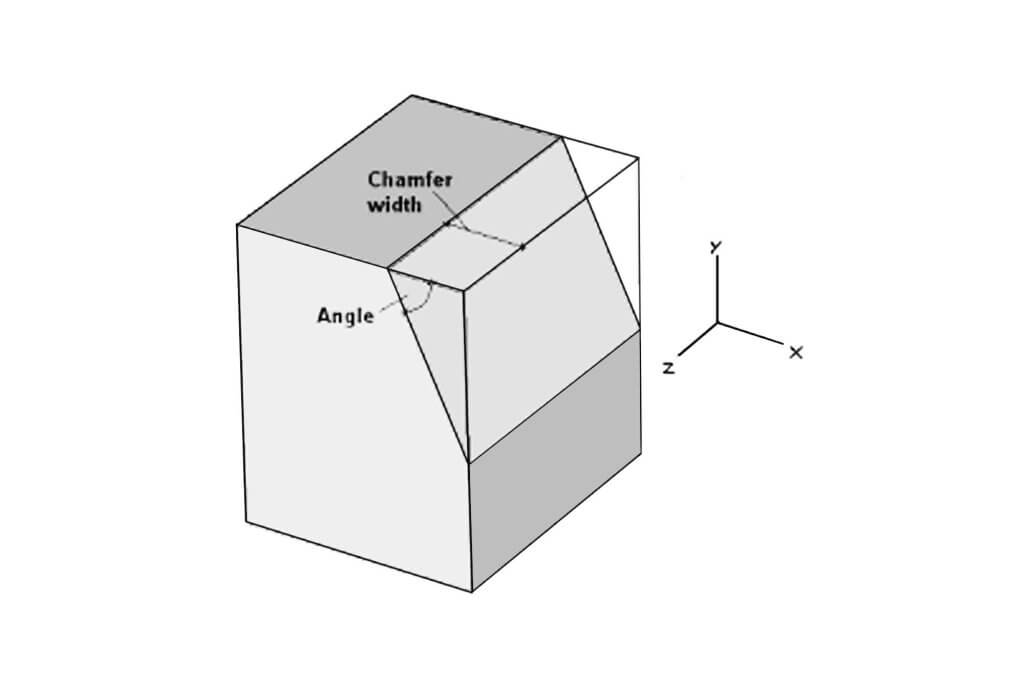

Chamfer in CNC Machining: A Complete Guide to Precision Edge Processing

Chapter 1: Introduction Chamfering is one of the most essential finishing operations in precision manufacturing. Over my many years working in CNC machining, I’ve discovered that a well-executed chamfer does more than just smooth out a sharp edge—it can dramatically enhance a part’s performance, assembly ease, and even safety. Custom Machining techniques allow us to tailor […]

Hex Bolt Manufacturing with CNC: From Standard to Custom Solutions

What is a Hex Bolt? Why is CNC Machining Important for Hex Bolts? Machining has always been an area I’ve enjoyed working in, particularly when it comes to CNC (Computer Numerical Control) machining. Over the years, I’ve had the opportunity to work with various fastening components, but one that keeps coming up time and time […]

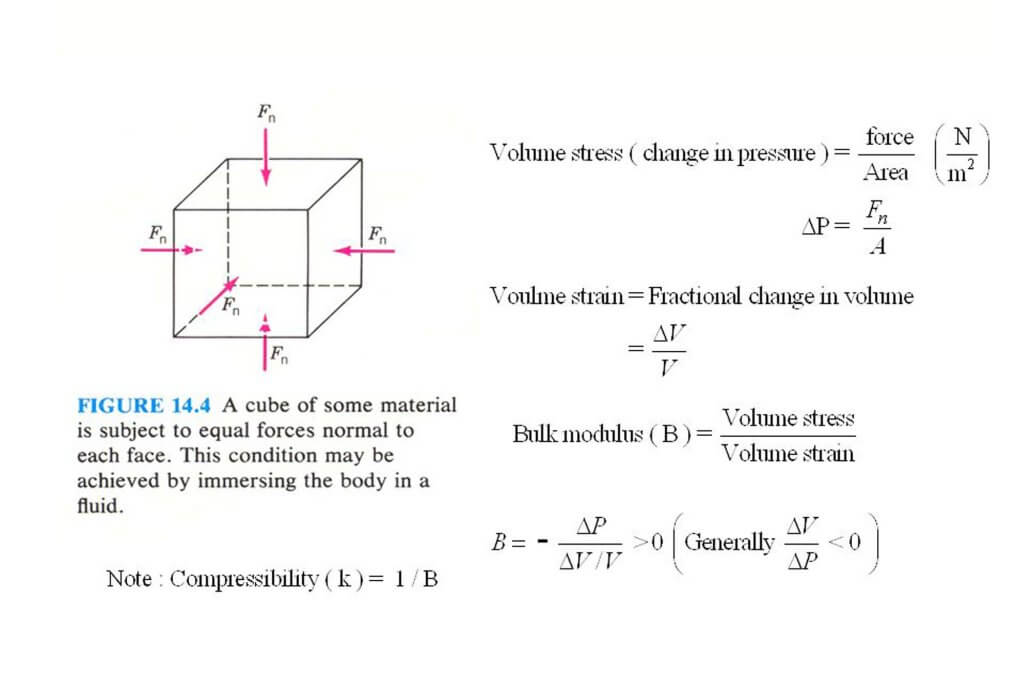

Bulk Modulus in Machining: How It Affects Material Selection and Cutting Performance

Part 1: Introduction – Why Bulk Modulus Matters in Machining Machining has always fascinated me. Over the years, as I’ve worked on various projects—from small CNC setups in my garage to larger production runs in industrial settings—I’ve noticed that one term keeps cropping up: Bulk Modulus. I’ve found that even in custom machining applications, this property […]

Knurling Techniques in CNC Machining: A Complete Guide for Engineers and Designers

Introduction to Knurling and CNC Machining Knurling is one of the most critical yet often overlooked processes in CNC machining, and I’ve come to appreciate its importance after years of hands-on experience. When I first encountered knurling in the field, I was immediately struck by how essential it is for improving both the functionality and aesthetics of […]

Mastering Machining for Carriage Bolts: A Guide to Custom Manufacturing

Introduction to Carriage Bolts and Custom Manufacturing Carriage bolts are widely used in various industries, providing a reliable and efficient solution for fastening wood, metal, and other materials. From construction projects to furniture assembly, these bolts are a go-to for many professionals. I first encountered carriage bolts in a personal DIY project, and what stood […]

Lattice Structure Customization: From Prototyping to Mass Production

Introduction The use of lattice structures is revolutionizing the way industries approach design, performance, and efficiency. From lightweight aerospace components to high-performance medical implants, lattice structures offer engineers the opportunity to create highly optimized parts that would otherwise be impossible with traditional materials. These structures, with their intricate, interconnected patterns, allow for significant reductions in material usage without compromising the strength or […]

Molly Bolt Customization: Best Machining Tips for Engineers

Introduction As engineers, we’re all familiar with the importance of using the right fastener in our projects. Whether it’s securing equipment to drywall or installing shelving in a residential space, the Molly bolt is a versatile solution that engineers have trusted for years. However, like any other fastening solution, there are situations where the standard Molly bolt just doesn’t […]

Main Bearing Performance Boost: How to Achieve It with CNC Machining

Chapter 1:Introduction I remember the first time I heard someone ask, “Isn’t a main bearing just a regular bearing?”My immediate thought was that a main bearing is more specialized than people assume.A main bearing supports a primary shaft in heavy machinery or engines, so it endures massive loads and high speeds. I’ve seen how critical […]

Afrikaans

Afrikaans Albanian

Albanian Amharic

Amharic Arabic

Arabic Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Chichewa

Chichewa Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Corsican

Corsican Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Esperanto

Esperanto Estonian

Estonian Filipino

Filipino Finnish

Finnish French

French Frisian

Frisian Galician

Galician Georgian

Georgian German

German Greek

Greek Gujarati

Gujarati Haitian Creole

Haitian Creole Hausa

Hausa Hawaiian

Hawaiian Hebrew

Hebrew Hindi

Hindi Hmong

Hmong Hungarian

Hungarian Icelandic

Icelandic Igbo

Igbo Indonesian

Indonesian Irish

Irish Italian

Italian Japanese

Japanese Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korean

Korean Kurdish (Kurmanji)

Kurdish (Kurmanji) Kyrgyz

Kyrgyz Lao

Lao Latin

Latin Latvian

Latvian Lithuanian

Lithuanian Luxembourgish

Luxembourgish Macedonian

Macedonian Malagasy

Malagasy Malay

Malay Malayalam

Malayalam Maltese

Maltese Maori

Maori Marathi

Marathi Mongolian

Mongolian Myanmar (Burmese)

Myanmar (Burmese) Nepali

Nepali Norwegian

Norwegian Pashto

Pashto Persian

Persian Polish

Polish Portuguese

Portuguese Punjabi

Punjabi Romanian

Romanian Russian

Russian Samoan

Samoan Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sesotho

Sesotho Shona

Shona Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Somali

Somali Spanish

Spanish Sundanese

Sundanese Swahili

Swahili Swedish

Swedish Tajik

Tajik Tamil

Tamil Telugu

Telugu Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Uzbek

Uzbek Vietnamese

Vietnamese Welsh

Welsh Xhosa

Xhosa Yiddish

Yiddish Yoruba

Yoruba Zulu

Zulu