What Is an OBJ File? How to Open, Convert, and Use It in 3D or Manufacturing Projects

What Is an OBJ File? If you’ve worked with 3D models, especially in design or printing, you’ve probably come across

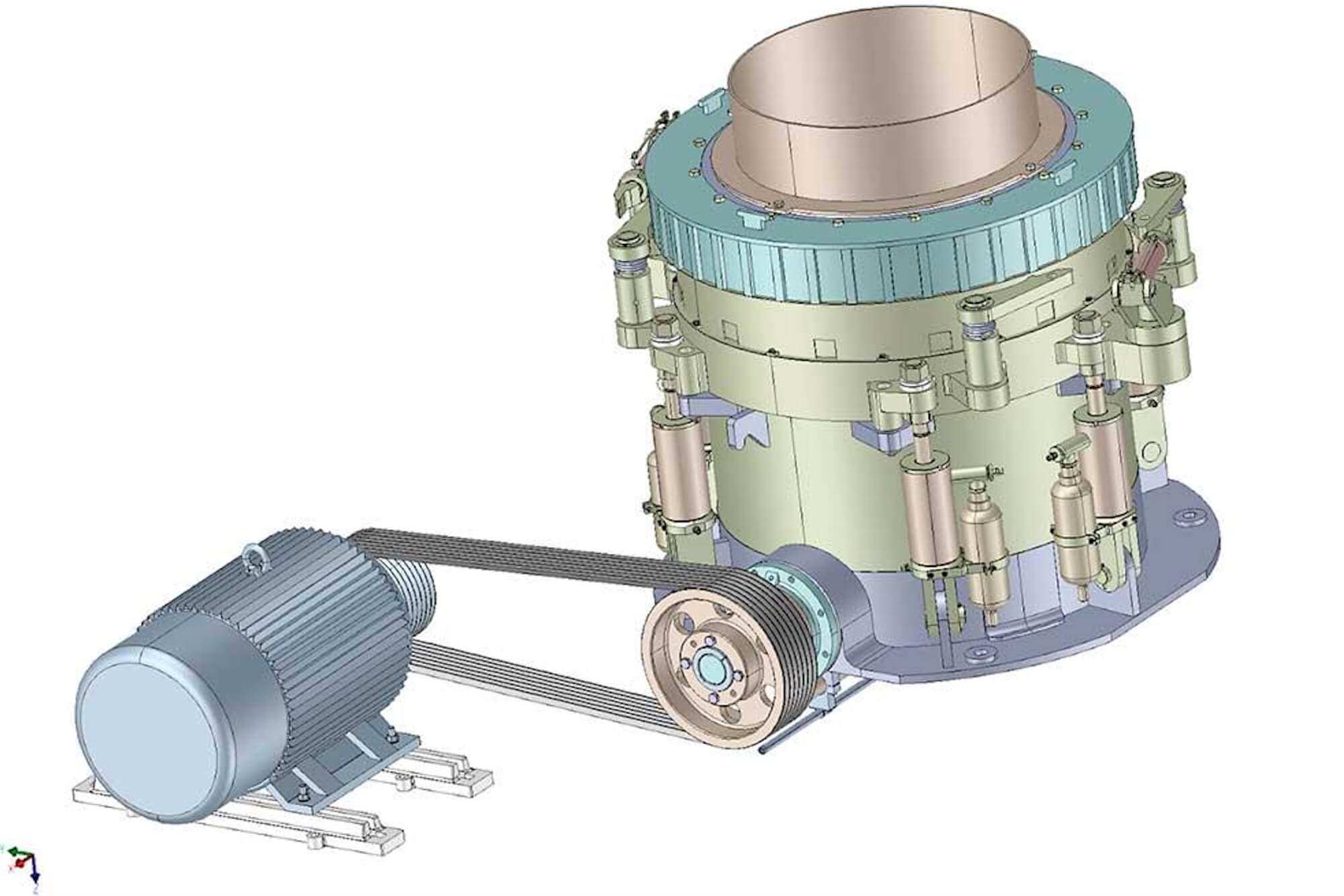

CNC software plays a pivotal role in modern manufacturing processes, allowing users to control the precise movements of machines and execute complex designs with unparalleled accuracy. In this category, we will explore the various types of CNC software available, their features, functionalities, and the benefits they bring to the CNC machining industry. Whether you are a seasoned professional in the field or a passionate hobbyist, this category will provide you with valuable insights, tips, and updates on the latest advancements in CNC software.

What Is an OBJ File? If you’ve worked with 3D models, especially in design or printing, you’ve probably come across

Introduction STL files are the heart of CNC machining, turning digital designs into tangible parts. An STL file, short for

Chapter 1: What is an STP File and Why It Matters in CNC An STP file (also called STEP file, with extensions

Introduction I remember the first time I used a DXF file for my CNC router. I had a design in my head,

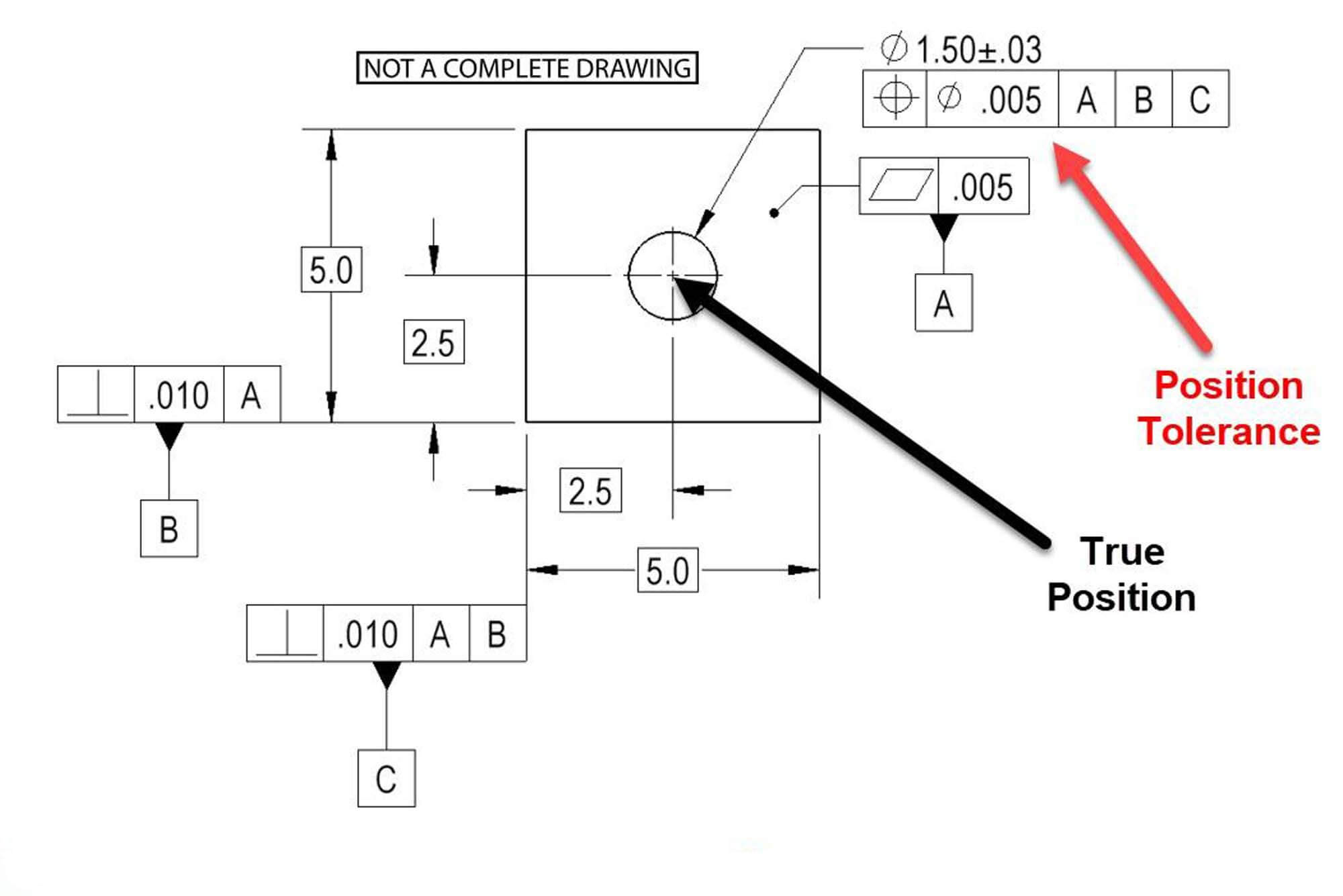

Introduction Overview of GD&T Symbols and CNC Geometric Dimensioning and Tolerancing (GD&T) is a language used to define the geometry and

Chapter 1. Introduction I remember the first time I tried converting stl to gcode for a simple 3D printing project.I

In the ever-evolving world of modern industry, research and development (R&D) investments are crucial for businesses to stay competitive. To

CNC machining has emerged as a go-to solution for manufacturing prototypes and parts involving cutting or drilling. This technology harnesses

CAM, or Computer-Aided Manufacturing, is a powerful technology used in CNC machining. It involves using computer software to control and automate

CAM, which stands for Computer-Aided Manufacturing, is a special kind of software that helps bridge the gap between design and

In today’s fast-paced manufacturing industry, Computer-Aided Manufacturing (CAM) acts as a bridge between design and production, enabling manufacturers to translate

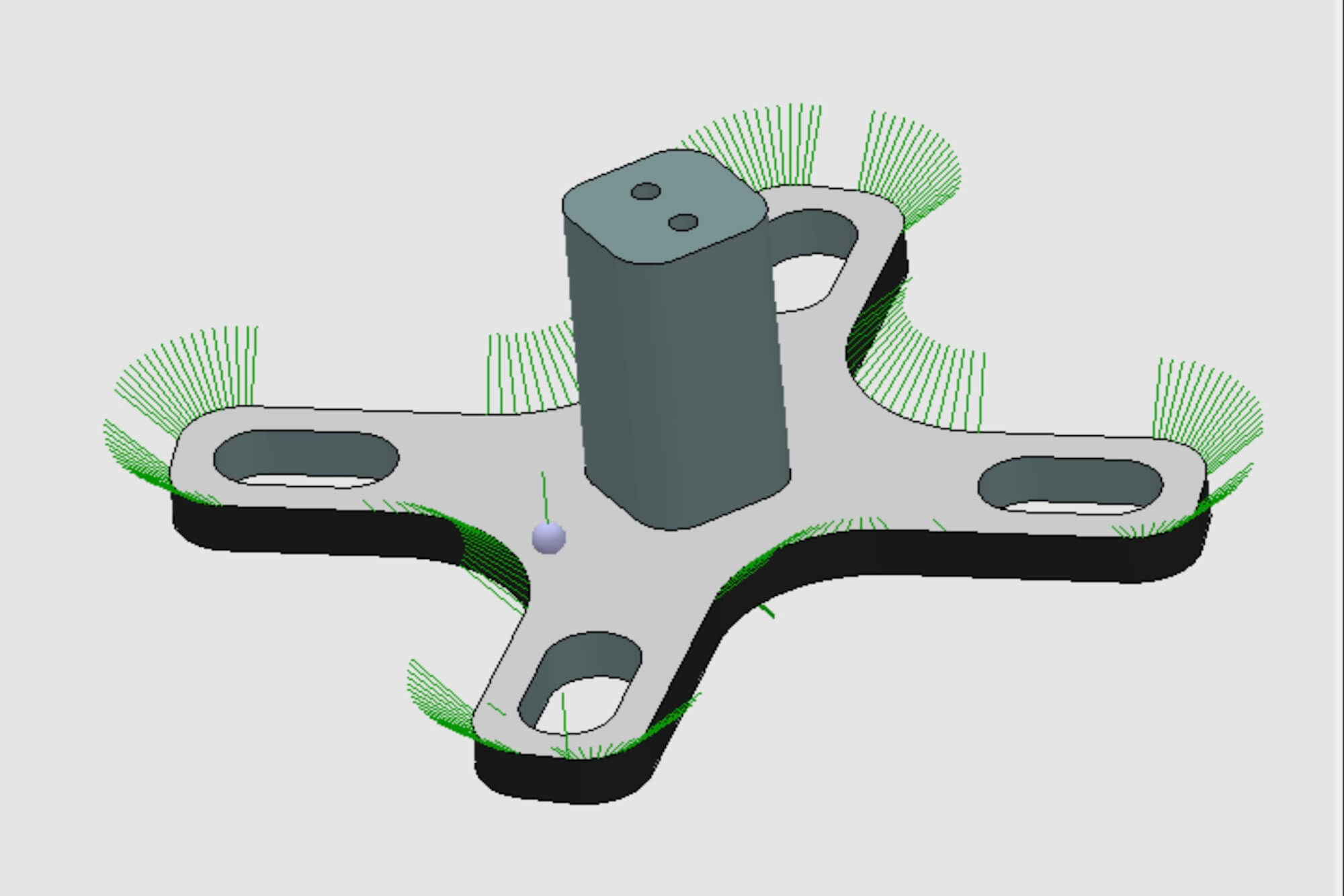

In this article, we will explore the essential steps to optimize your CAD models for CNC machining. We will delve

You’re one step from the factory-direct price of part manufacturing services.