Part Structural Processability

Selection of Blank Forming Methods and Machining Processability In the process of mechanical manufacturing, selecting appropriate blank forming methods and

Selection of Blank Forming Methods and Machining Processability In the process of mechanical manufacturing, selecting appropriate blank forming methods and

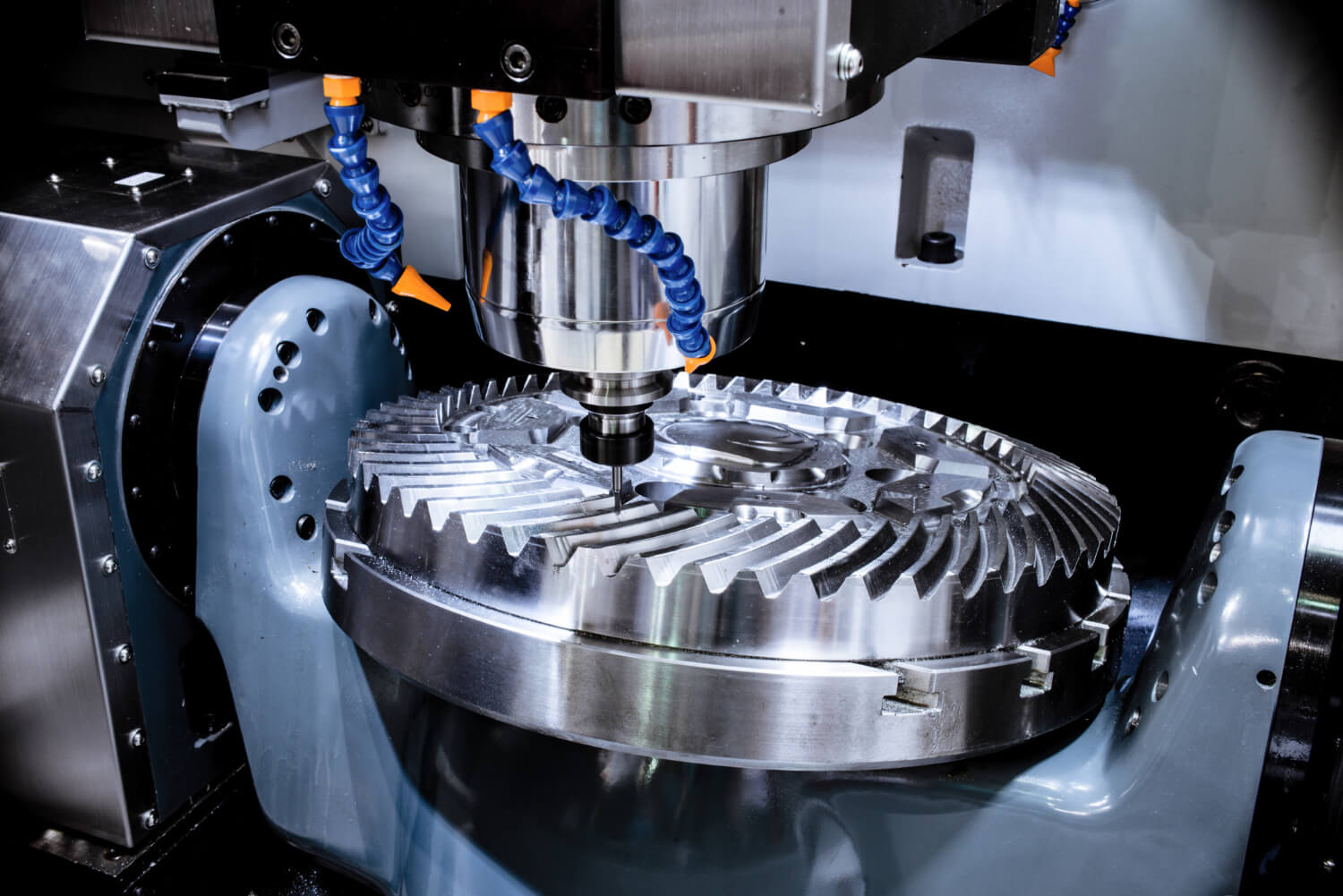

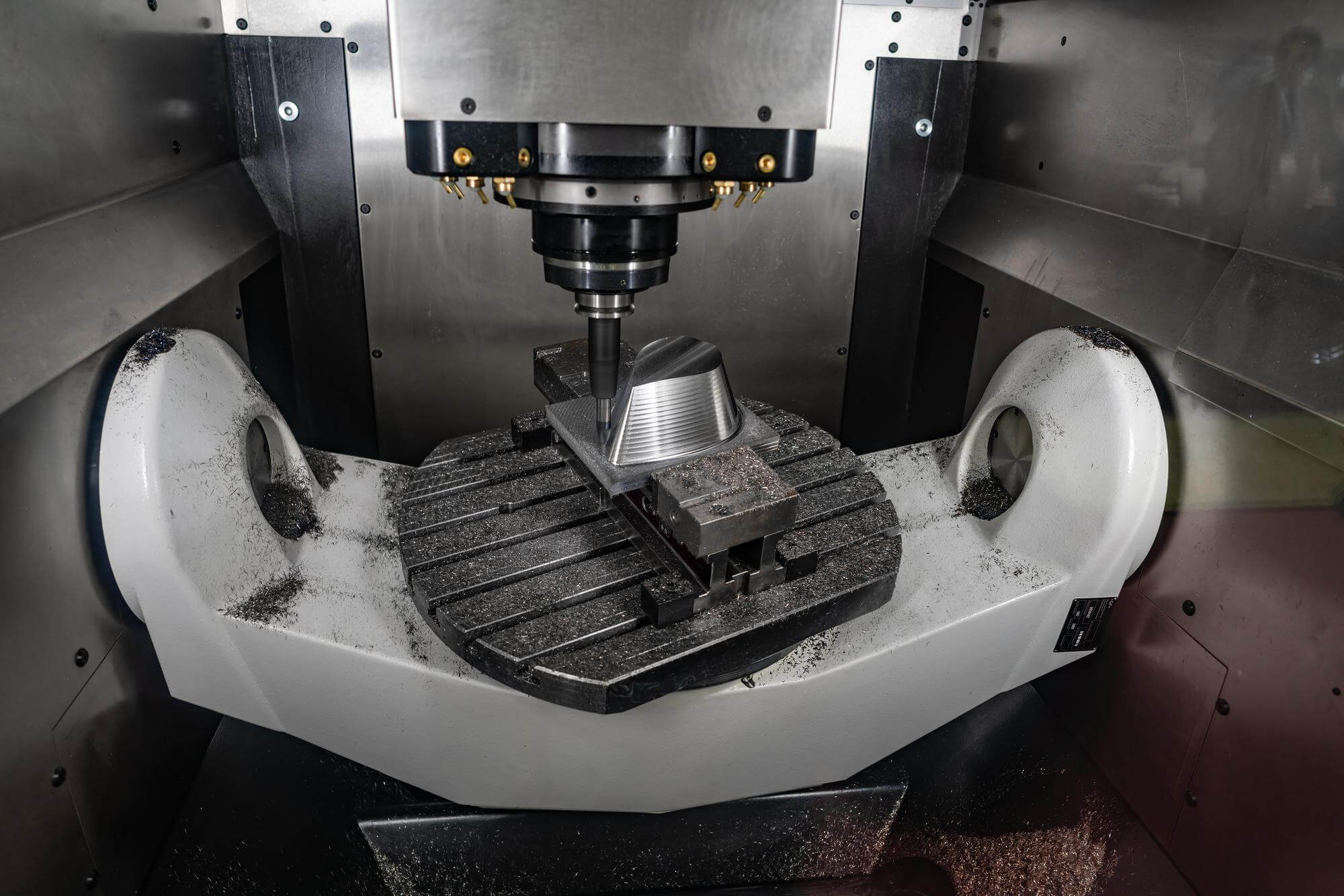

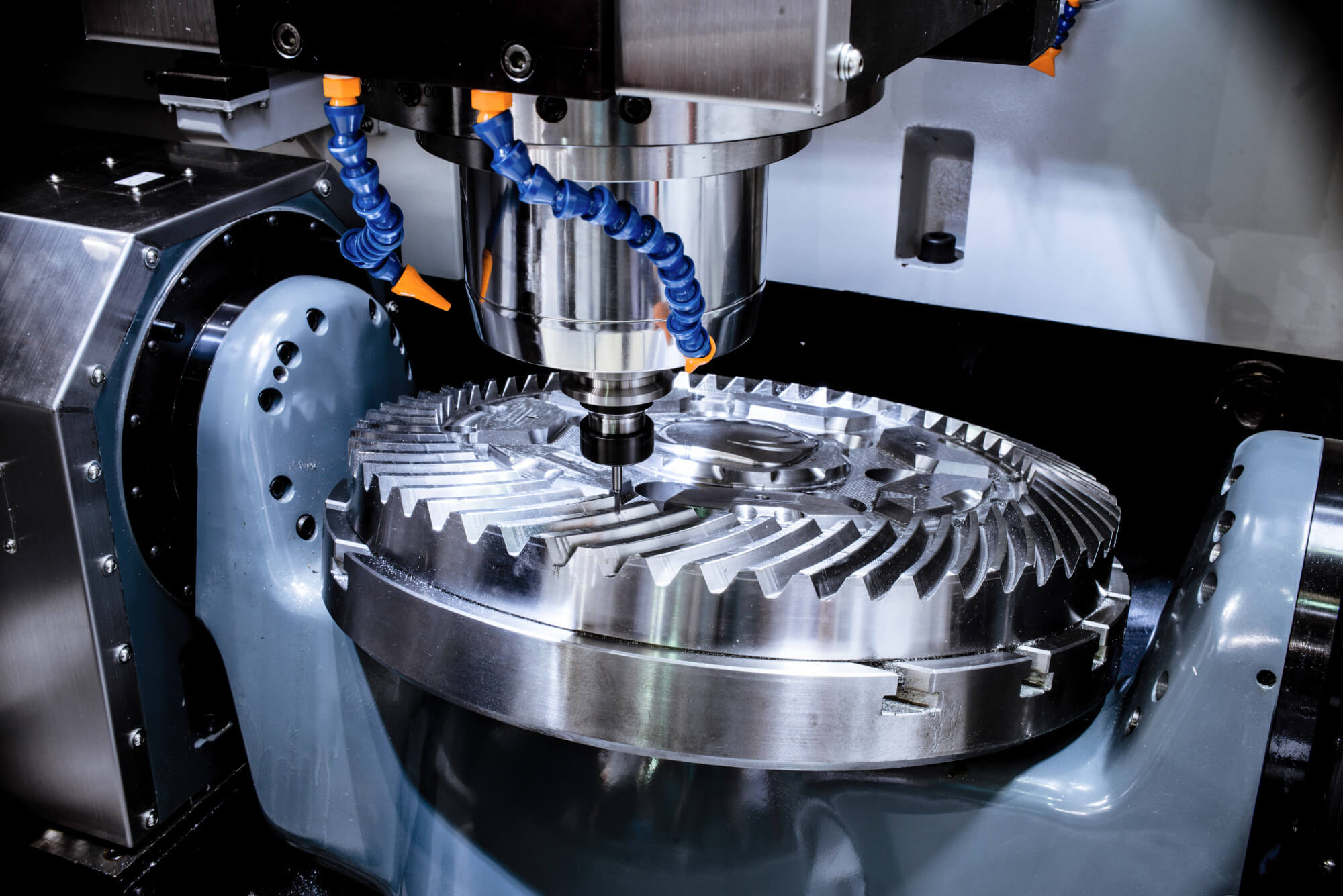

In the world of mold and aerospace machining, two-dimensional cavity machining stands out as one of the most material-intensive and

In mechanical manufacturing, selecting and forming blanks are critical factors that influence product quality, cost, and performance. Choosing the right

Many metals naturally form a protective oxide film on their surfaces, a process known as passivation. Chemical conversion films take

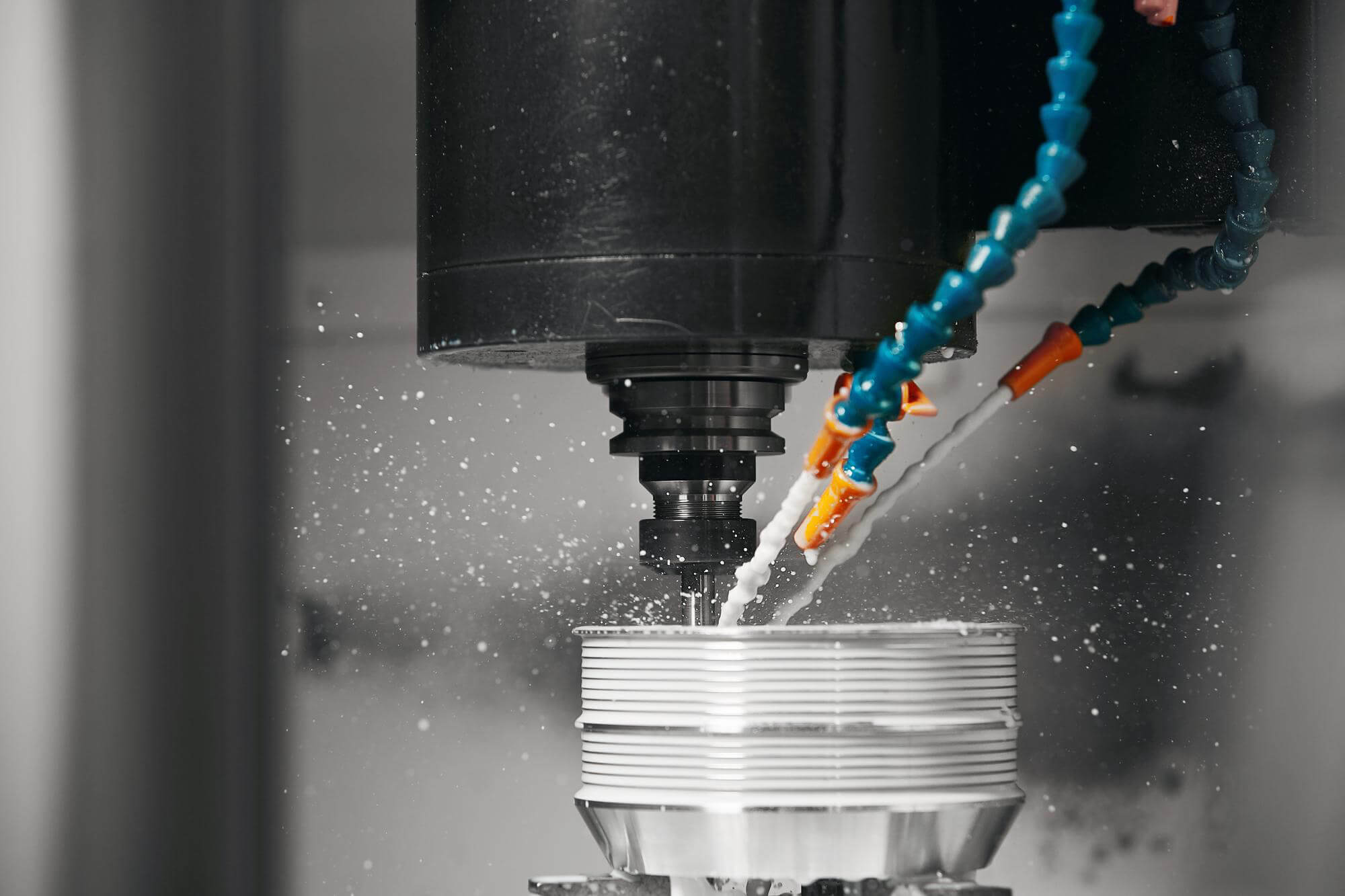

High-speed cutting (HSM or HSC) is not just a technological advancement; it’s a fascinating journey of innovation that has transformed

Boring holes with precision and quality in CNC machining can be a bit tricky, but with the right techniques, it

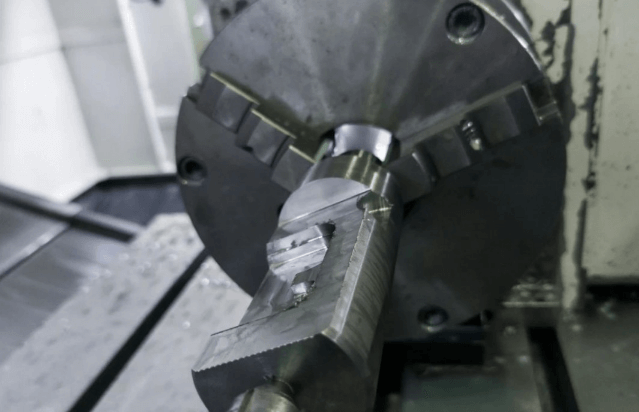

The Basics of CNC Turning-Milling Compound Machining Programming The programming basics for CNC turning-milling compound machining can vary due to

Surface quality in machining refers to the overall condition of a part’s surface after machining, encompassing its geometric shape, physical-mechanical

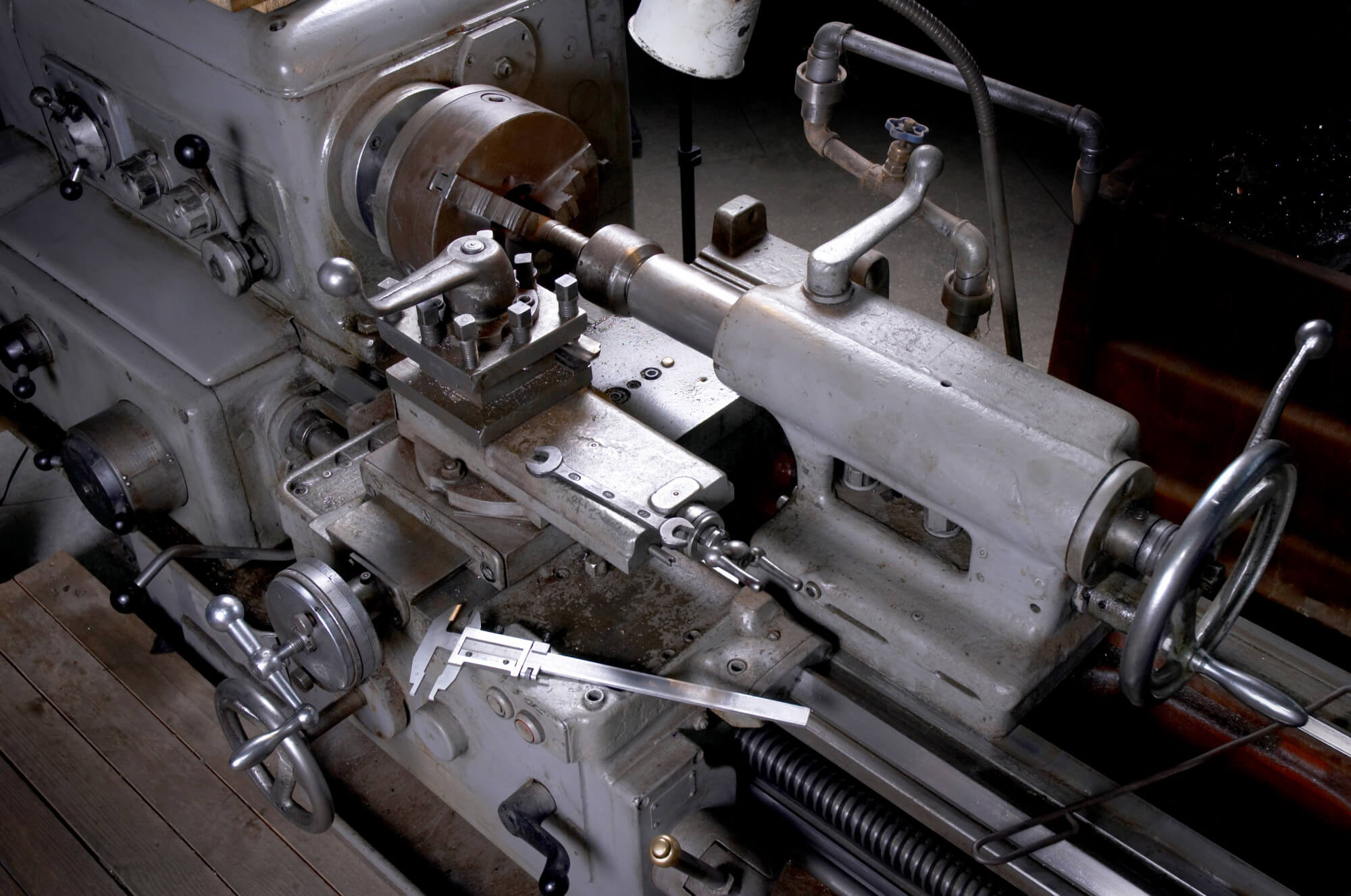

Shaft Parts Machining Function of Shaft Parts Shaft parts are primarily used to support transmission components and transmit torque. Common

What is CNC Machining Boring CNC boring is an advanced machining process that uses computer numerical control (CNC) technology to

Introduction Aluminum alloy frame parts are like the unsung heroes of the aerospace industry. These components, found in aircraft frames,

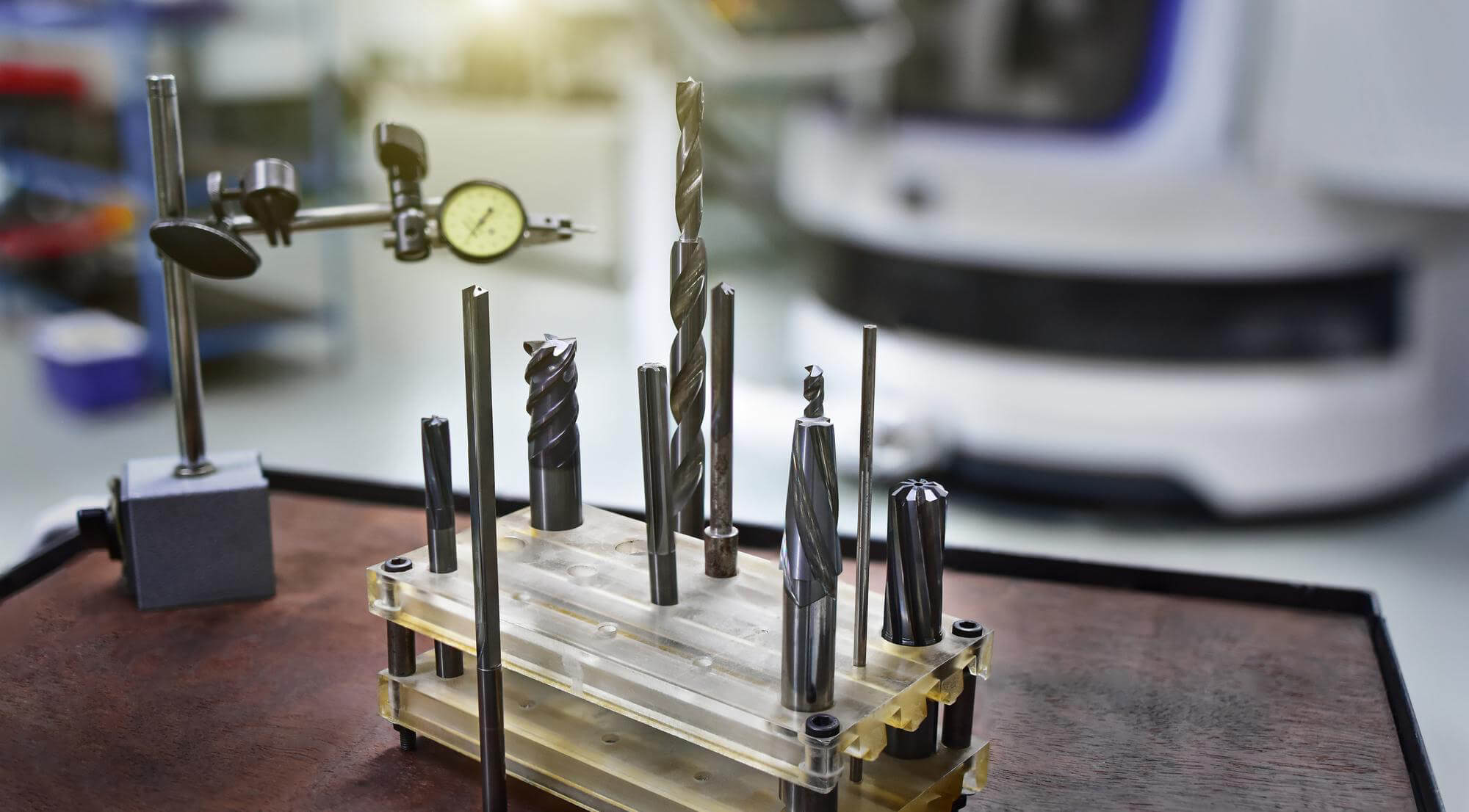

Introduction Reaming might not be the most glamorous topic in the world of CNC machining, but it’s an essential process

en

en