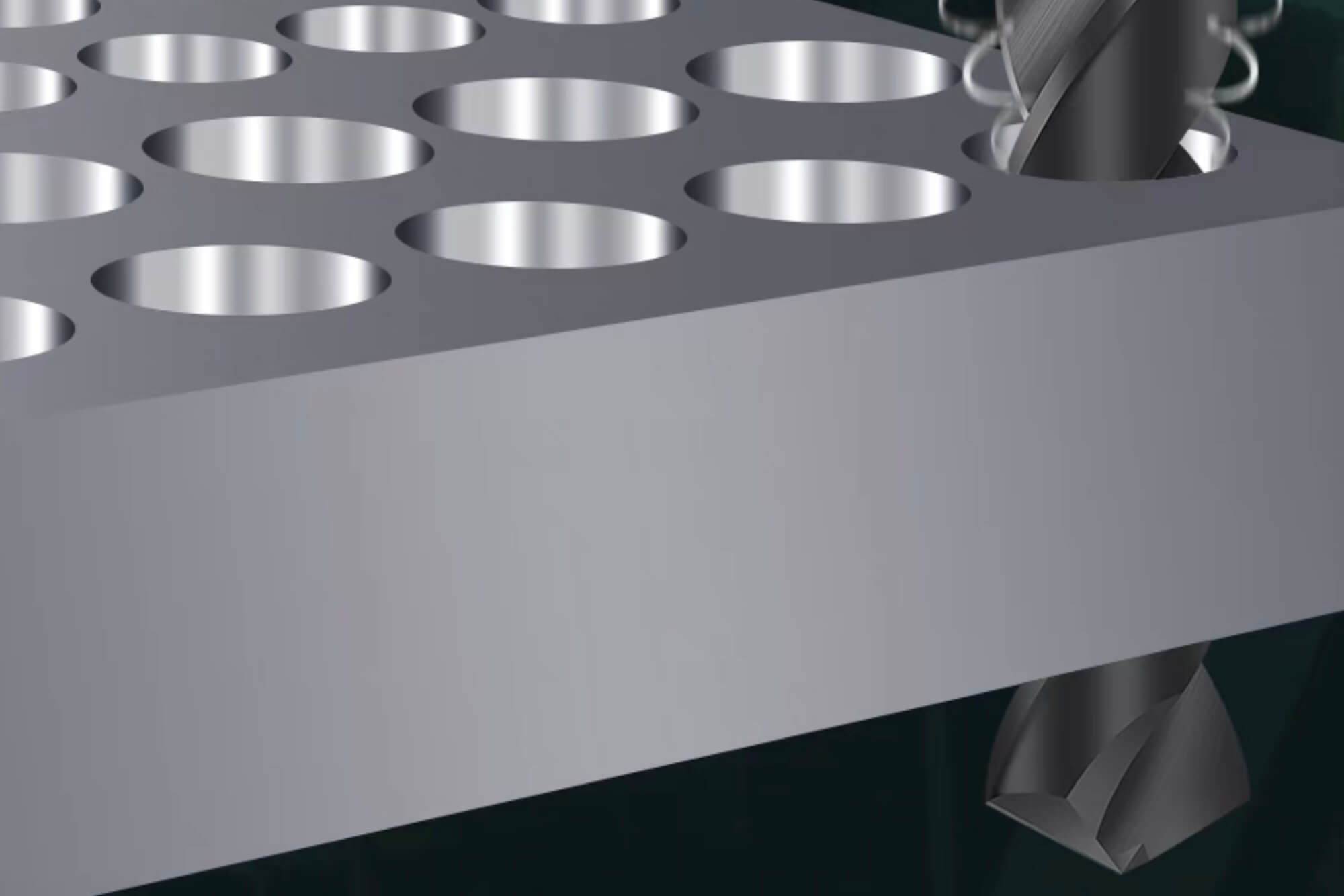

Titanium Drill Bits in CNC: Boost Efficiency Today

Introduction: Unlock Efficiency with Titanium Drill Bits in CNC Titanium drill bits are game-changers for CNC machining. If you’re working

Introduction: Unlock Efficiency with Titanium Drill Bits in CNC Titanium drill bits are game-changers for CNC machining. If you’re working

Introduction: The Role of Polyester Material in Modern Manufacturing I still remember the first time I stumbled upon polyester material

Introduction I’ve always found “alloy steel” to be a fascinating subject. There’s so much depth to it, from its versatile

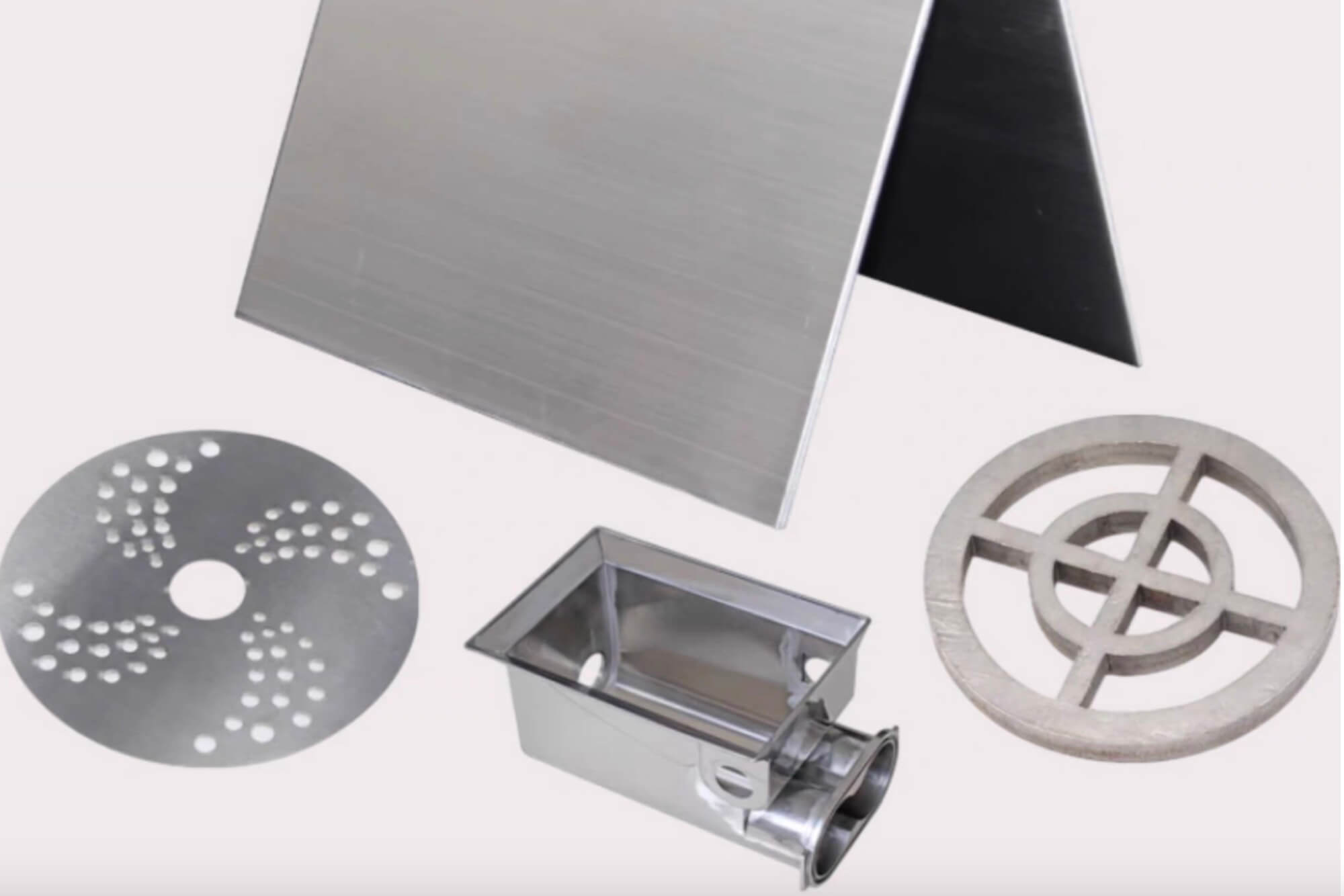

Introduction I’ve worked with all kinds of metals in various shops. Over time, I’ve come to see why 316 stainless steel is

Introduction I’ve spent years working with different metals, but stainless steel has always held a special place in my workshop.

Introduction I still recall the day I had to choose a material for a small test project back when I

Introduction I remember the first time I dealt with Self Tapping Screws in a production setting. I was an intern,

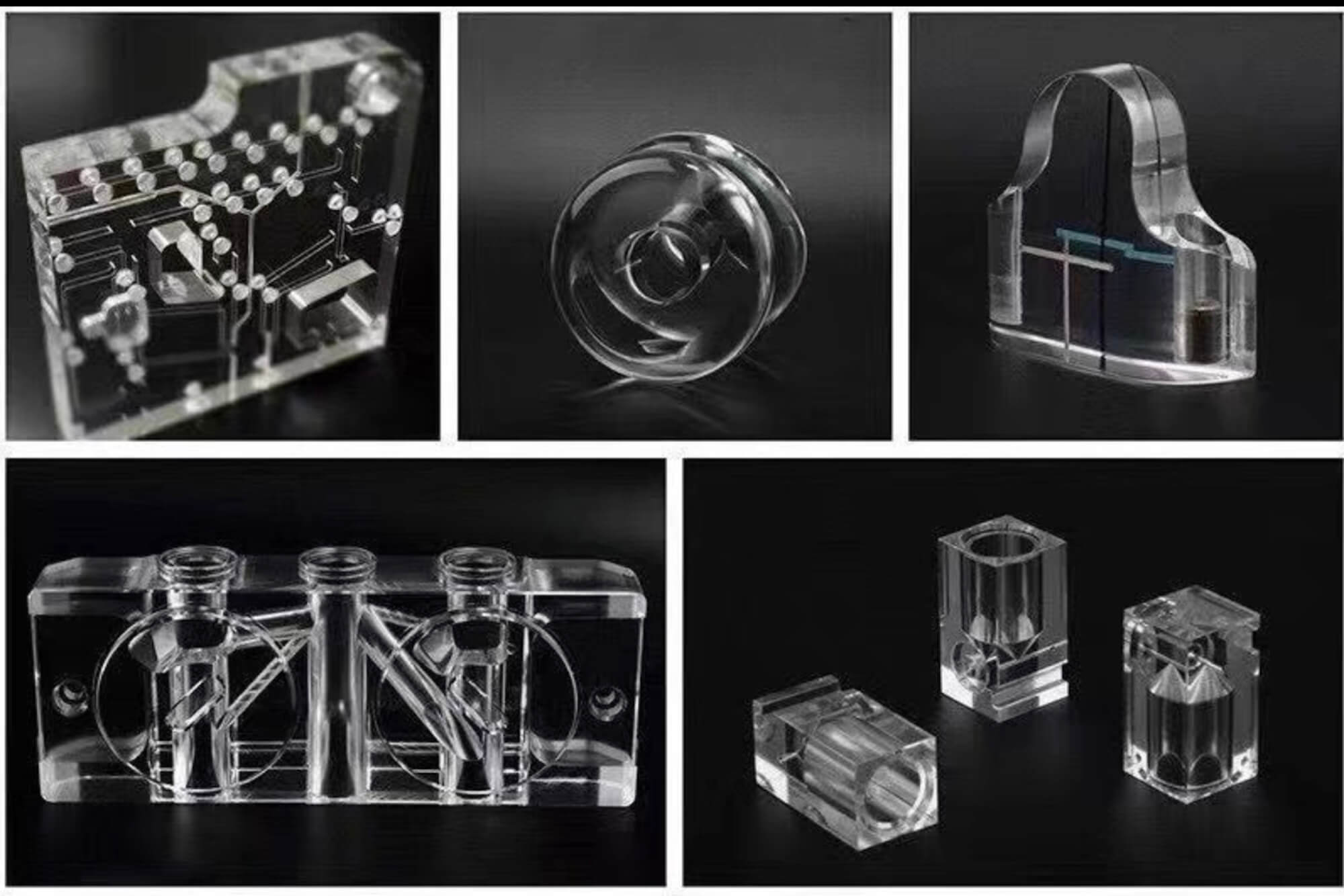

Introduction Several years ago, when I was managing a small manufacturing shop, I first encountered the term “CNC fabrication.” At that time,

Introduction to C-276 Alloy 1.1 Why C-276 Alloy? When I first encountered c-276 alloy, I was looking for a material that

Part 1: Introduction If you’re like me and work with automotive, heavy machinery, or any industry that involves precision mechanical

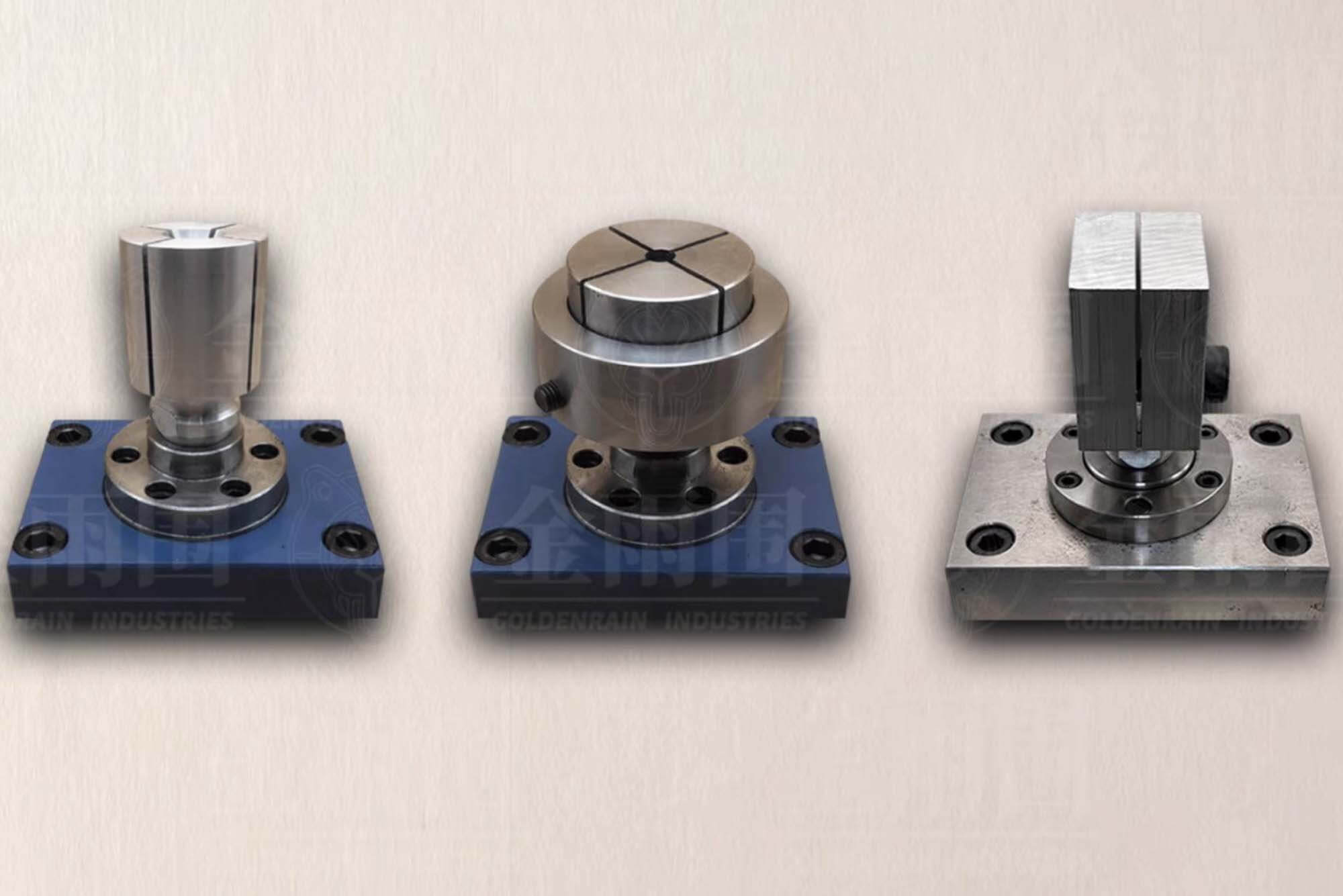

Introduction Jigs are the unsung heroes of CNC machining, making sure every cut lands exactly where it should. In manufacturing,

Introduction If you’re involved in construction, metal fabrication, or precision machining like me, you’ve probably encountered galvanized square steel. Galvanized square

You’re one step from the factory-direct price of part manufacturing services.