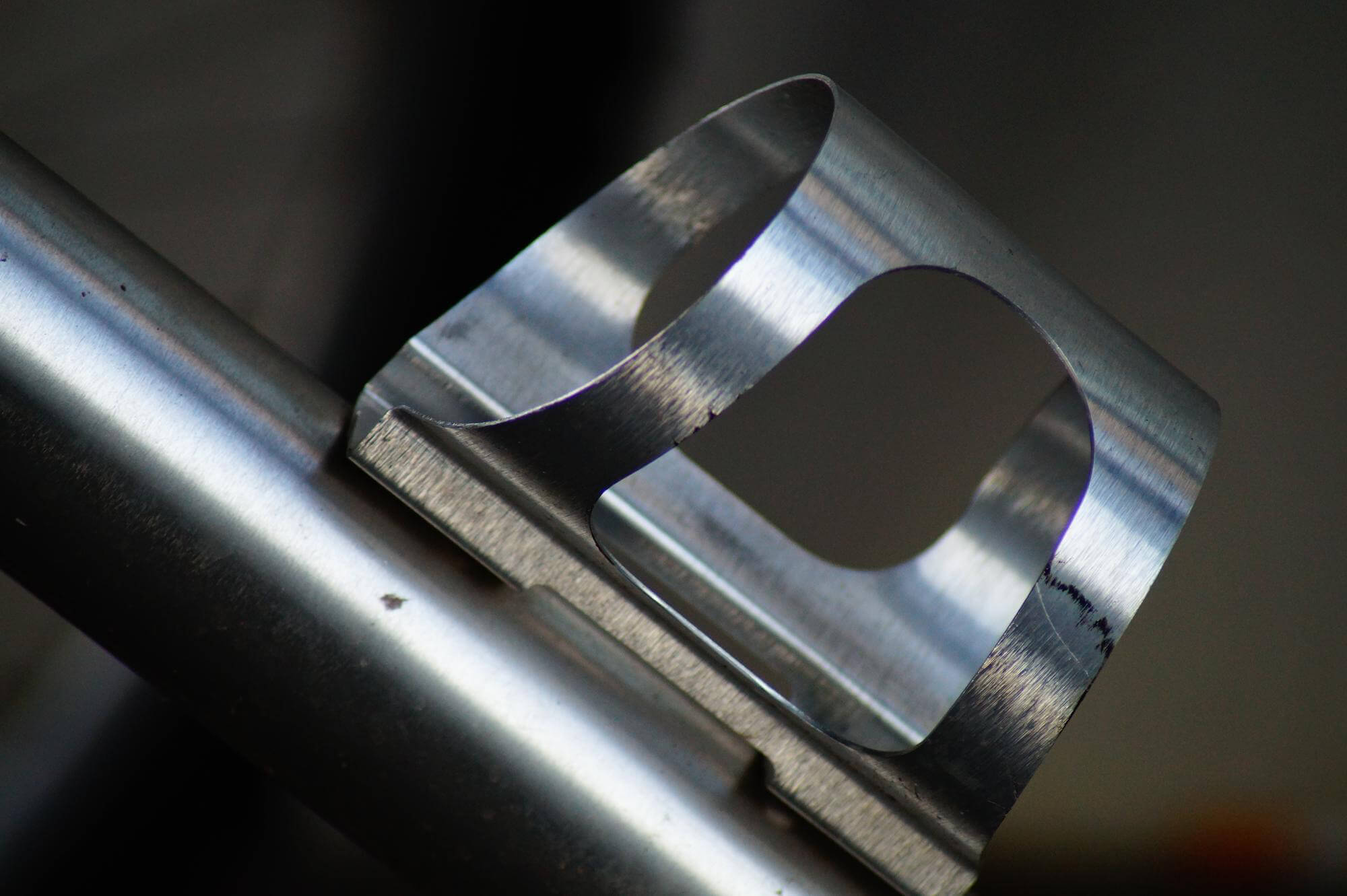

What Are the Challenges of CNC Machining Thin-Walled Stainless Steel Parts?

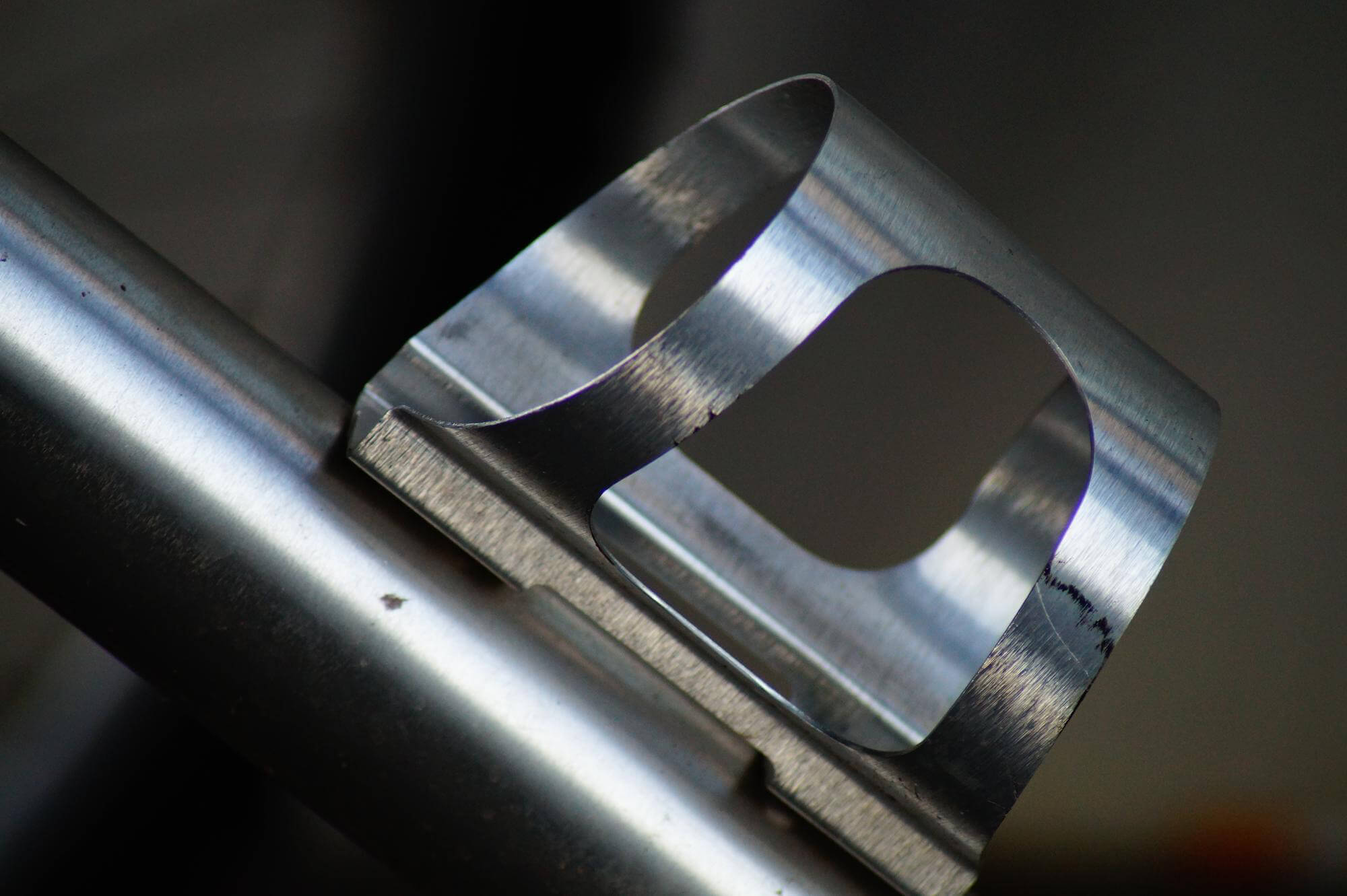

Understanding Thin-Walled Stainless Steel Parts Thin-walled stainless steel parts are essential in various industries due to their unique properties. These

Understanding Thin-Walled Stainless Steel Parts Thin-walled stainless steel parts are essential in various industries due to their unique properties. These

Technical Challenges in Precision CNC Machining of Copper Precision CNC machining of copper involves various technical challenges due to its

Introduction: Brief Overview of CNC Machining and Its Importance in the Aerospace Industry Computer Numerical Control (CNC) machining is a

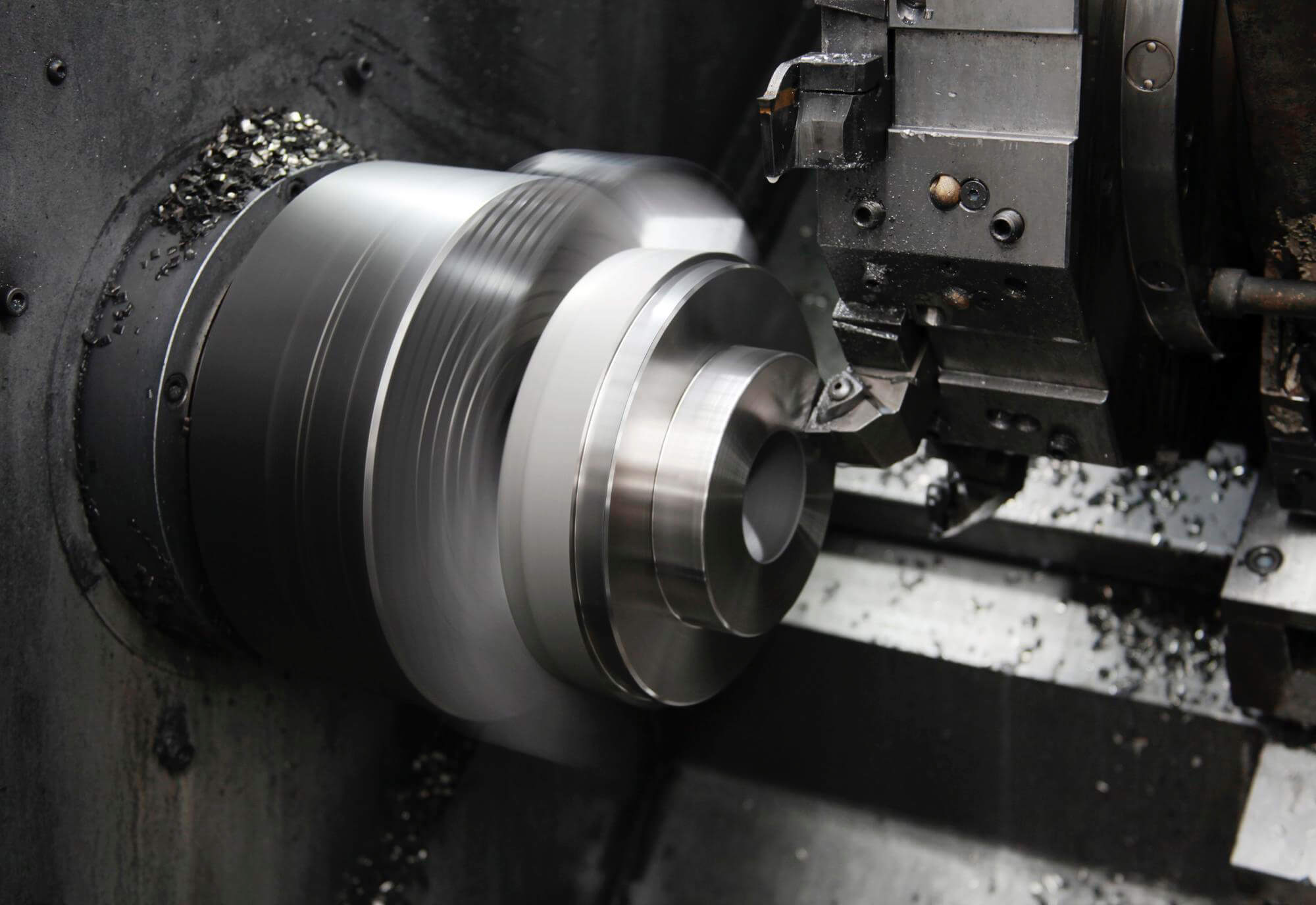

Introduction: Understanding the Function and Importance of Stainless Steel Machining The process of Stainless Steel machining involves shaping stainless steel

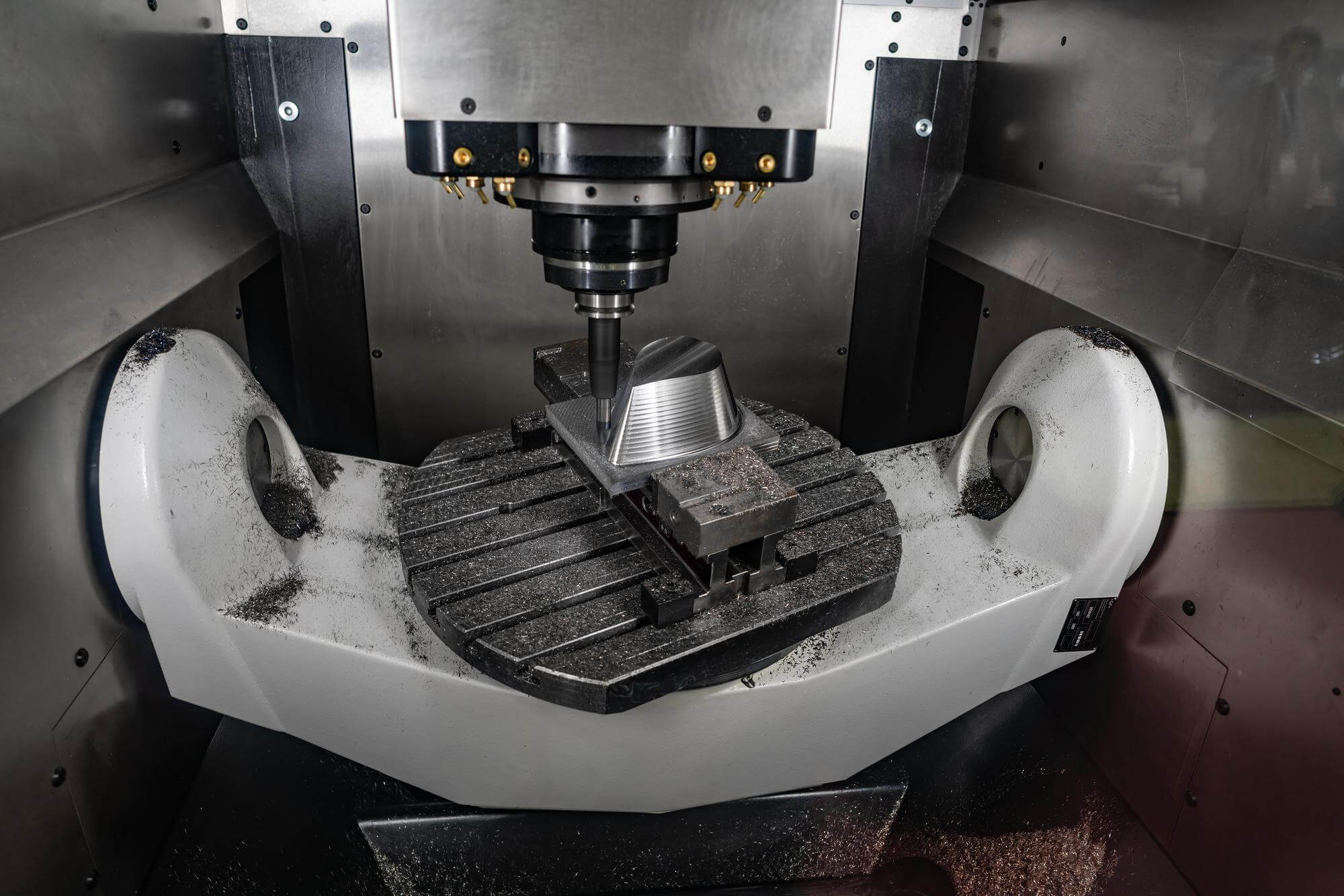

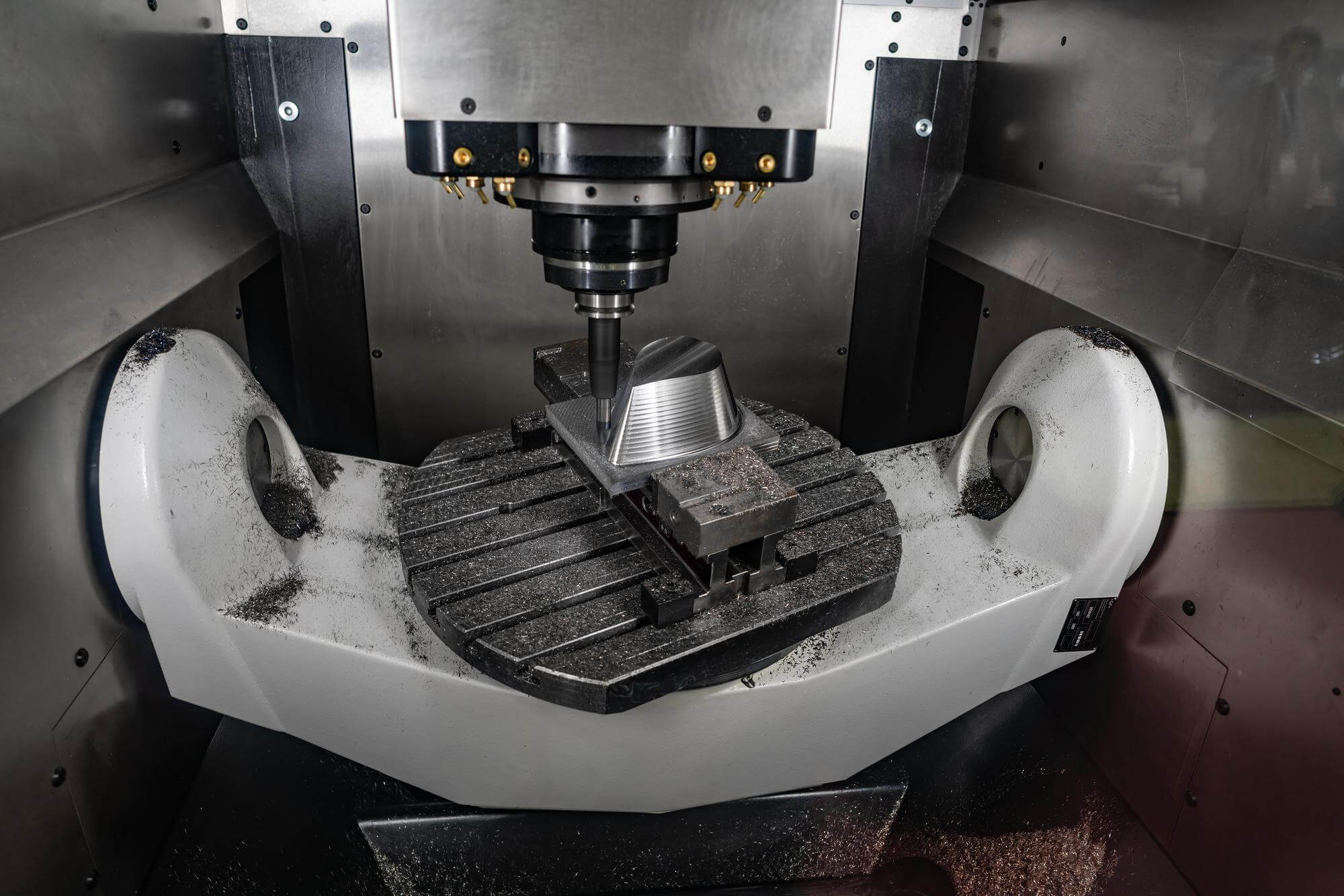

Introduction to 5-Axis CNC Machining and its Role in Manufacturing Industry The revolutionary technique of Five-axis Computer Numeric Control machining,

Plastic manufacturing involves the process of converting plastic raw materials into final products through various techniques. These techniques range from

What Are the Global Import Regulations for Brass CNC Machining Parts? The global landscape for importing brass CNC machining parts

High-speed machining (HSM) is an intriguing and evolving field within CNC machining. The term “high-speed” is relative and varies depending

How Are Global Market Dynamics Shaping the Sourcing of Brass CNC Machining Parts? The global landscape for sourcing brass CNC

In the world of CNC machining, creating precise and complex parts from aluminum alloys is a common yet challenging task.

Mechanical preprocessing When it comes to CNC machining, achieving a perfect surface finish is crucial. It’s not just about making

Peck drilling, also known as intermittent feed drilling, is an essential technique in the world of CNC machining. It uses

You’re one step from the factory-direct price of part manufacturing services.