Acetal vs Delrin for Machining: A Complete Guide for Engineers and Designers

Introduction When I first started working with plastics in CNC machining, one question kept coming up: Acetal vs Delrin – what’s the difference, and which one should I use? It sounded like a simple choice, but it wasn’t. Both materials are part of the same plastic family, yet they perform differently depending on the use case. This […]

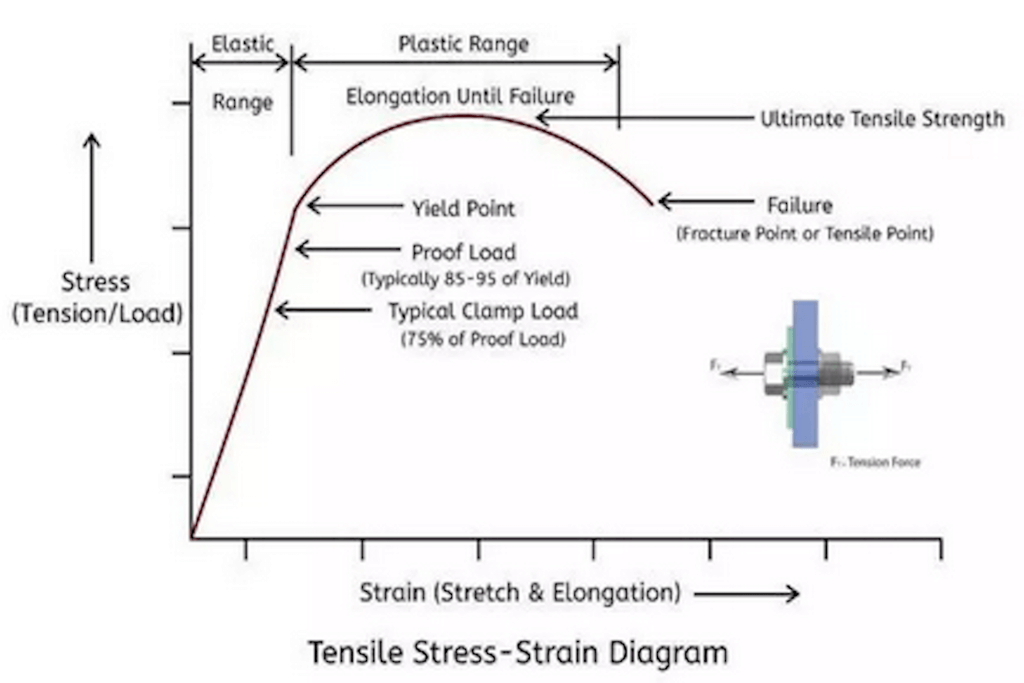

Tensile Strength of Steel Explained for Engineers and Machinist

Introduction The tensile strength of steel is the heartbeat of engineering and machining. It’s the maximum stress a steel part can endure before snapping, and it’s a make-or-break factor for safe bridges, durable gears, or reliable chassis. I learned this lesson painfully early in my career. While designing a steel bracket for an industrial press, […]

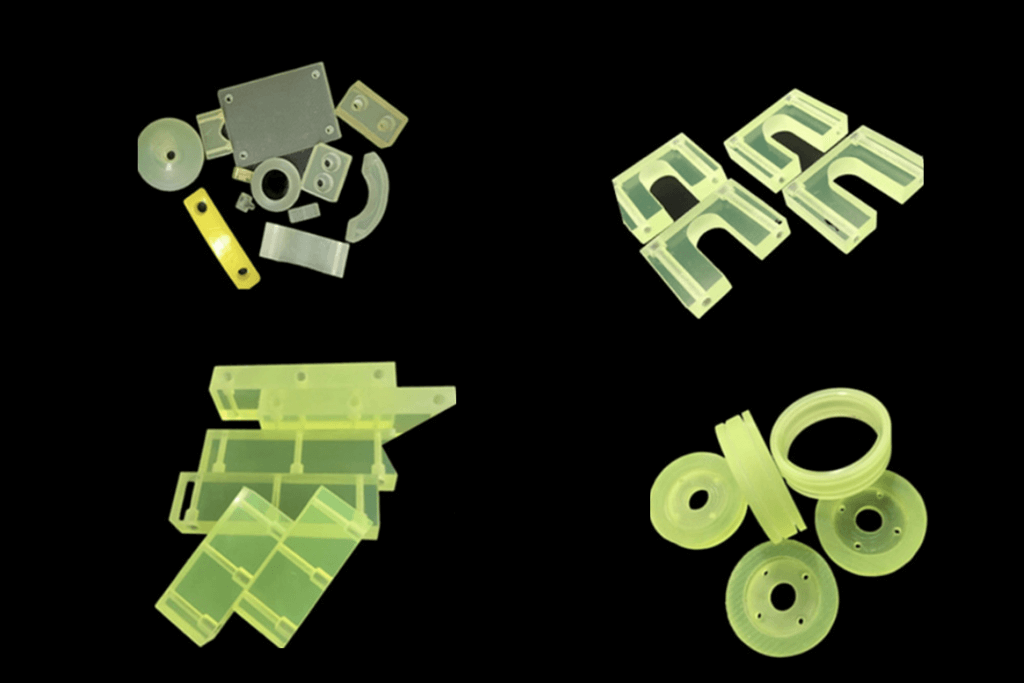

How Urethane is Machined in Modern Manufacturing: Tips, Tools, and Real-World Use Cases

Introduction I’ve been fascinated by the way Urethane shapes modern manufacturing ever since I first encountered this material in a small prototyping workshop. It was early in my career, and I remember wondering if it could be machined as easily as metals or more common plastics. Back then, I was juggling multiple projects, and I […]

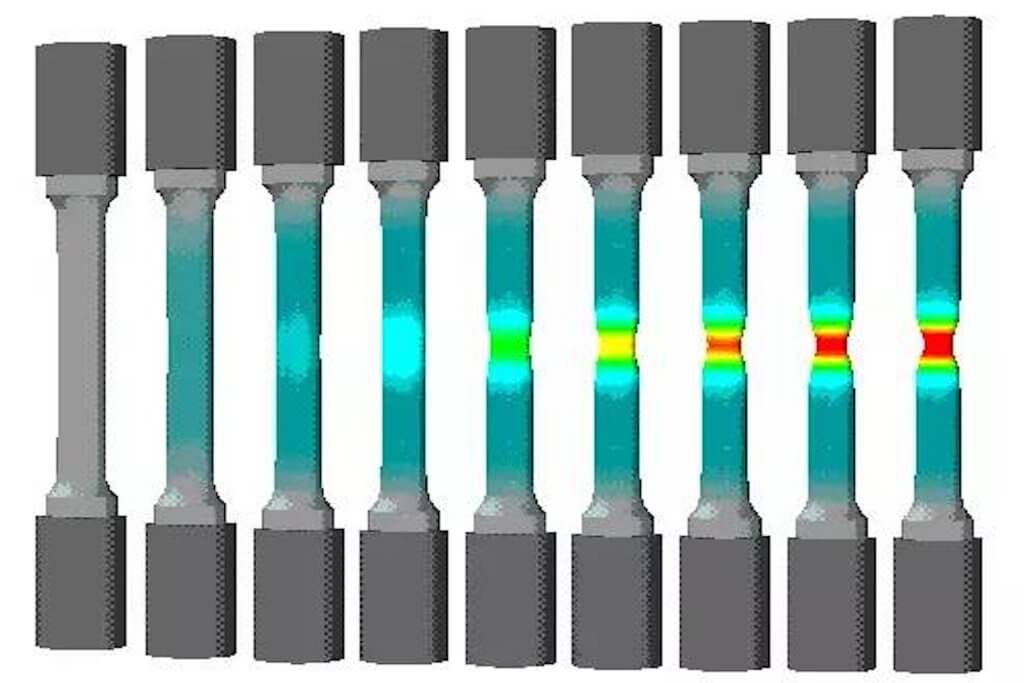

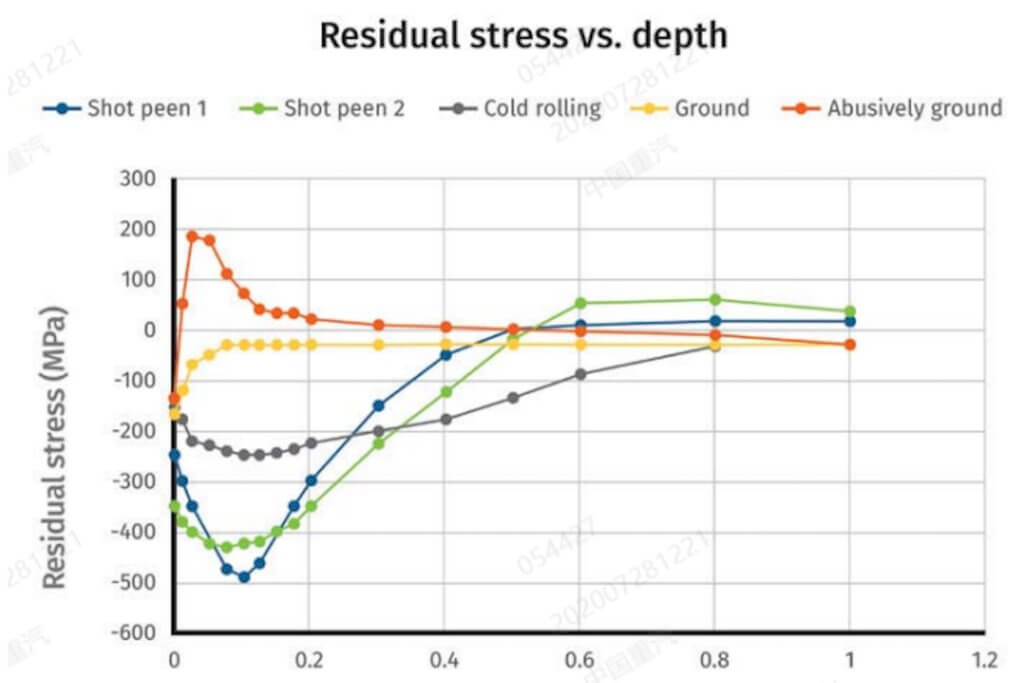

The Ultimate Guide to Stress Relieving for CNC Parts: When, Why, and How

Introduction Stress relieving has always been a point of fascination for me. I remember the first time I discovered how much of a difference it makes in CNC machined parts. I was visiting a friend’s small fabrication shop in the Midwest. We were working on a batch of steel components for a heavy machinery client. […]

How to Cut, Drill, and Modify ABS Pipe Using CNC Machines

Introduction ABS pipe is everywhere—from plumbing systems to DIY projects, from prototypes to structural parts in lightweight assemblies. But recently, I’ve noticed a growing trend: people want to take their ABS pipe applications further with precision customization, using CNC machines. I’ve done it myself, and it can be incredibly rewarding—when done right. This article is […]

HDPE Machining Guide: Material Properties, Techniques and Applications

Introduction to HDPE and CNC Machining I remember the first time I encountered HDPE. I was working on a small project that required a lightweight, food-safe, and chemically resistant plastic. A friend mentioned HDPE (High-Density Polyethylene), and I was intrigued. I did some research and realized that HDPE offers a pretty interesting balance of strength, durability, and ease of machining. […]

Yield Strength vs Tensile Strength: CNC Material Choice and Process Optimization

I. Introduction 1. Definition of Yield Strength and Tensile Strength I remember the first time I encountered the terms yield strength and tensile strength in my early machining projects. Yield strength refers to the stress level at which a material begins to deform permanently. When stress is lower than the yield point, the material returns to its original shape […]

Plexiglass vs Acrylic: A Complete Guide to Properties, Applications, and Fabrication for Your Project Needs

I. Introduction: Why Compare Plexiglass and Acrylic? I’ve noticed that many people—myself included—sometimes wonder about the differences between plexiglass and acrylic. Both terms are often used interchangeably. But there are subtle distinctions worth exploring. When I first started working with clear plastics, I often questioned which material was truly better: plexiglass vs acrylic? Would I benefit […]

Custom Acrylic Frames Guide: Techniques, Tools, and Best Practices

Introduction Acrylic frames are widely appreciated for their elegance, durability, and versatility across various industries. Whether it’s for advertising displays, home decor, or precision-made electronic enclosures, acrylic frames provide a sleek, modern appearance that enhances any design. In this guide, I will share everything I’ve learned about custom acrylic frames and how to use CNC […]

Brass Screws Custom Machining Guide: Techniques, Tools, and Best Practices

Introduction Brass screws are among the most popular fasteners used across various industries due to their unique combination of aesthetics, corrosion resistance, and excellent machinability. If you’re considering CNC machining custom brass screws, you’re making an excellent choice. I’ve personally seen brass screws used effectively in electronics, decorative items, precision instruments, and more. In this […]

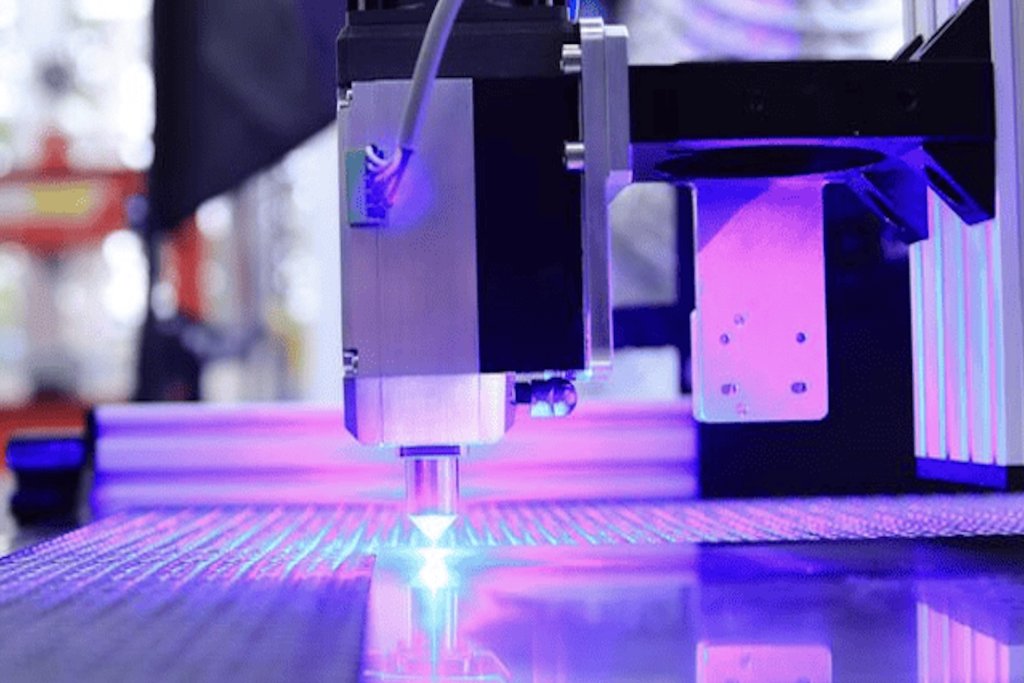

Laser Cut Acrylic: A Complete Guide to Precision CNC Cutting Techniques and Best Practices

Introduction When I first started using CNC laser cutting technology, acrylic quickly became my favorite material.It’s versatile, beautiful, and easy to shape into detailed designs.But achieving the perfect laser cut acrylic result isn’t always straightforward. I’ve experienced challenges like burnt edges, inaccurate cuts, and inconsistent finishes.Over the years, I’ve learned how to overcome these issues.Now, […]

Best CNC-Cut Acrylic Signs for Retail and Events: Design and Production Guide

Chapter I:Introduction I want to start by sharing how I first realized the power of CNC-cut acrylic signs.I was working with a small retail client who wanted eye-catching store signage without spending a fortune on metal letters or neon.We tried standard plastic letters, but they lacked the modern appeal we aimed for.Eventually, we discovered acrylic […]