Why Chamfered Edge Matters in CNC Machining

A chamfered edge may seem like a small detail in machining, but it is a critical element in both design and manufacturing. This beveled or sloped edge, typically cut at a 45-degree angle, enhances a component’s functionality and aesthetics. From improving safety by eliminating sharp edges to ensuring smoother assembly, chamfered edges serve a wide array of purposes across industries.

CNC machining, known for its precision and versatility, is the preferred method for creating chamfered edges. The ability to program complex chamfers with consistent accuracy makes CNC machining indispensable in industries like automotive, aerospace, electronics, and consumer products.

When I first encountered chamfered edges during a CNC machining project, I was struck by their versatility. Whether the goal was to improve safety, enhance assembly, or create a polished appearance, chamfered edges provided the ideal solution. In this article, I’ll delve into the significance of chamfered edges, the techniques used in CNC machining, and the various applications that make them a cornerstone in modern manufacturing.

Chamfered Edge: Types and Functional Benefits

A chamfered edge is a transitional surface created between two intersecting faces of an object. It softens sharp corners, improves usability, and enhances the overall appearance of a product. Chamfered edges can vary in shape, size, and angle, depending on their application and design requirements.

Types of Chamfered Edges

- Straight Chamfer:

A uniform sloped edge, typically cut at a 45-degree angle.

Commonly used in mechanical components such as bolts, nuts, and machine housings to facilitate assembly and reduce wear. - Rounded Chamfer (Fillet Chamfer):

A combination of a chamfer and a rounded edge to create a smoother transition between surfaces.

Ideal for applications where reducing stress concentration is crucial, such as medical devices and aerospace components. - Decorative Chamfer:

Designed primarily for aesthetics, these chamfers enhance the visual appeal of consumer products like electronics and luxury goods. - Complex Chamfer:

- These feature variable angles or intricate patterns tailored for specialized applications, such as turbine blades or precision molds.

| Chamfer Type | Characteristics | Applications |

|---|---|---|

| Straight Chamfer | Uniform slope, typically 45 degrees | Bolts, mechanical components |

| Rounded Chamfer | Blended slope and curve | Stress-reduction parts, medical devices |

| Decorative Chamfer | Designed for visual appeal | Electronics, consumer goods |

| Complex Chamfer | Custom angles or patterns | Aerospace, precision tools |

Functional Benefits of Chamfered Edges

- Improved Safety:

Sharp edges can pose risks in handling and operation. Chamfered edges eliminate these hazards, ensuring a safer user experience.

For instance, stair railings with chamfered edges are less likely to cause injuries in high-traffic areas. - Enhanced Assembly:

Chamfered edges guide components during assembly, making the process smoother and reducing the chances of misalignment.

Automotive manufacturers often rely on chamfers in engine components to improve gasket seating and alignment. - Aesthetic Appeal:

A chamfered edge gives a polished, professional look to products, particularly in consumer goods and electronics.

Smartphones with chamfered edges not only look sleek but also provide a more comfortable grip. - Stress Distribution:

By softening sharp transitions, chamfered edges minimize stress concentration, extending the lifespan of parts.

This is particularly important in high-stress environments like aerospace and heavy machinery.

In my experience, even a simple chamfer can drastically improve a product’s usability and lifespan. It’s a feature that often goes unnoticed by the end user but is critical to the product’s performance.

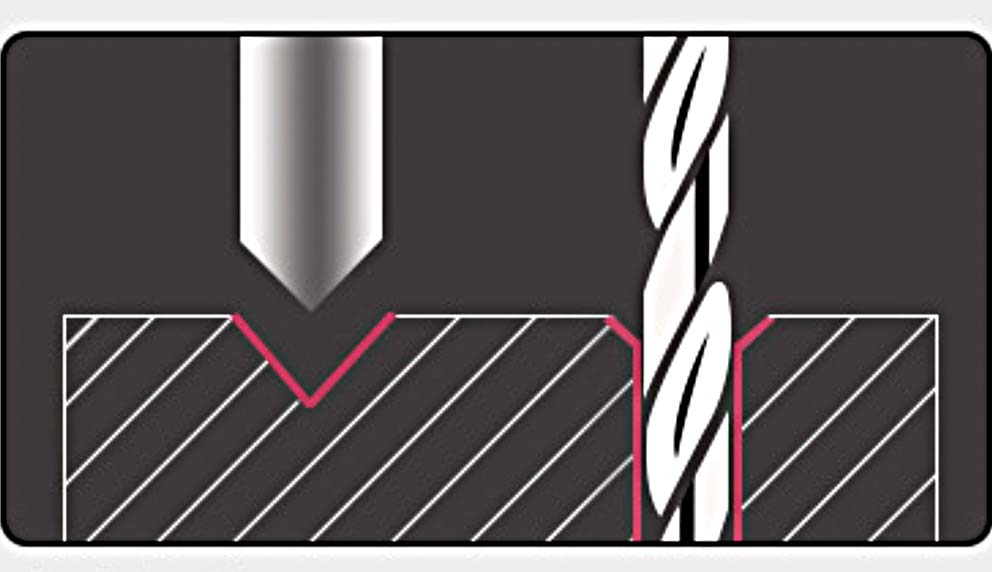

Techniques for Creating Chamfered Edges with CNC Machines

Creating a precise chamfered edge with CNC machining involves careful planning, proper tool selection, and accurate programming. These techniques ensure that the chamfers meet design specifications while maintaining the highest quality standards.

How CNC Machines Achieve Chamfered Edges

- Toolpath Programming:

CNC machines use toolpaths defined in CAM (Computer-Aided Manufacturing) software to create chamfers.

Operators use G-codes such as G01 (linear interpolation) and G02/G03 (circular interpolation) to achieve straight or curved chamfers.

Dimensions such as depth, angle, and length are precisely defined to meet the design requirements. - Tool Selection:

Chamfer Mills: These tools are specifically designed for creating chamfers and are available in various angles, such as 30°, 45°, and 60°.

Countersink Tools: Ideal for creating conical chamfers around holes.

End Mills: Useful for small chamfers and other dual-purpose machining tasks. - Material Considerations:

The material being machined significantly impacts the parameters used for chamfering.

Softer materials like aluminum allow higher cutting speeds, while harder materials like stainless steel or titanium require lower speeds and robust tooling.

| Parameter | Recommended Settings |

|---|---|

| Spindle Speed (RPM) | 500–2000 (depending on material) |

| Feed Rate (mm/min) | 100–500 |

| Chamfer Angle (degrees) | Typically 45, adjustable per design |

| Tool Type | Chamfer mill, countersink tool, end mill |

Programming Tips for Accurate Chamfers

- Simulate the Process:

Use simulation software to check for errors before actual machining. This saves time and prevents material wastage. - Perform Multiple Passes:

For deep chamfers, use multiple passes to avoid excessive tool wear and ensure a consistent finish. - Adjust Feed Rates:

Slower feed rates produce smoother chamfered edges, especially on harder materials.

Advanced Techniques:

In a recent project involving aerospace-grade titanium components, we used 5-axis CNC machining to create complex chamfered edges. This method allowed us to achieve intricate designs with impeccable precision, demonstrating the versatility of modern CNC technology.

Real-World Applications of Chamfered Edges in CNC Machining

Chamfered edges are a universal design element found across multiple industries. They provide both functional and aesthetic advantages that enhance the usability, safety, and visual appeal of products. Below, we explore how chamfered edges are used in various industries and the value they bring.

1. Automotive Industry

Chamfered edges are vital in the automotive sector, where precision and durability are paramount.

- Applications:

Engine Components: Chamfers guide parts like pistons and valves during assembly, ensuring proper alignment and fit.

Bolts and Screws: Chamfered edges make threading easier, reducing wear during assembly.

Structural Parts: Parts such as brackets and joints use chamfers to minimize stress concentrations, extending their lifespan. - Case Example:

While machining engine blocks for a leading car manufacturer, we incorporated chamfered edges into the cylinder heads. This improved the gasket seating and ensured a tight, secure fit, reducing the risk of leaks and enhancing engine performance.

2. Electronics Industry

Modern electronics demand sleek designs, ergonomic handling, and precise assembly—all of which chamfered edges contribute to.

- Applications:

Device Housings: Chamfers provide smooth transitions between surfaces, making devices like smartphones more comfortable to hold.

Connectors and Ports: Chamfers on USB ports and cable connectors ensure smooth plug-in and reduce wear over time. - Case Example:

For a smartphone project, chamfered edges were added to the aluminum casing to give it a premium, polished look. CNC machining allowed us to achieve consistent angles and a flawless finish, meeting both functional and aesthetic demands.

3. Aerospace

In aerospace, chamfered edges are critical for both safety and performance.

- Applications:

Structural Components: Chamfers reduce sharp edges on critical parts, minimizing stress points that could lead to fatigue or failure.

Fasteners: Chamfered edges on rivets and bolts ensure secure assembly even under extreme conditions. - Case Example:

When machining titanium components for an aircraft landing gear system, chamfered edges were added to distribute stress evenly and prevent micro-cracks during operation.

4. Construction and Architecture

Chamfered edges are a common design feature in both functional and decorative architectural elements.

- Applications:

Metal Railings and Frames: Chamfers eliminate sharp corners, enhancing safety and aesthetic appeal.

Decorative Panels: Chamfers add depth and dimension to wall panels, improving their visual impact. - Case Example:

For a modern building project, CNC-machined metal panels with chamfered edges were used to create a clean, contemporary look while ensuring the panels were safe to handle during installation.

5. Medical Devices

In the medical industry, precision and biocompatibility are key. Chamfered edges improve the safety and functionality of medical devices.

- Applications:

Surgical Tools: Chamfered edges reduce sharpness, minimizing the risk of accidental cuts during procedures.

Implants: Chamfers ensure a smooth interface between implants and bones, improving patient comfort.

Benefits Across Industries

The versatility of chamfered edges makes them indispensable across industries. Whether enhancing safety, improving assembly, or elevating design, chamfered edges deliver unparalleled value.

Common Challenges in Chamfered Edge Machining and Solutions

Machining chamfered edges, while straightforward in concept, can present challenges in practice. These issues can arise from material properties, tool wear, or improper programming. Here’s how to identify and address common problems:

Common Challenges and Their Solutions

| Challenge | Cause | Solution |

|---|---|---|

| Inconsistent Dimensions | Misalignment during machining or programming errors | Calibrate workholding fixtures and validate CNC program parameters. |

| Tool Wear and Breakage | Hard materials or prolonged usage | Use coated tools like TiN (Titanium Nitride) or DLC (Diamond-Like Carbon) coatings. |

| Burr Formation | High cutting speeds or dull tools | Reduce spindle speed and use sharp, high-quality chamfer mills. |

| Surface Roughness | Inadequate cooling or incorrect feed rate | Apply efficient cooling systems and optimize feed rates. |

| Overheating | Excessive friction during machining | Use appropriate cooling fluids and decrease cutting depth per pass. |

Troubleshooting Tips

Tool Inspection: Regularly inspect tools for wear to maintain consistent performance.

Material Testing: Conduct test runs on scrap material to fine-tune machining parameters.

Monitor Machine Calibration: Ensure that all machine axes are properly aligned and calibrated.

Chamfered Edge Tools and CNC Technologies

The tools and technologies used in CNC machining play a pivotal role in creating precise and consistent chamfered edges. Advanced tools and techniques can enhance efficiency, reduce errors, and improve the final product’s quality.

1. Tools for Chamfered Edges

- Chamfer Mills: Specifically designed for creating chamfers, these tools come in various angles and sizes.

- Countersink Tools: Ideal for chamfering around holes, creating clean, beveled edges.

- Multi-Purpose End Mills: These tools can handle smaller chamfers and other tasks, offering versatility in machining.

| Tool Type | Best Use Case | Advantages |

|---|---|---|

| Chamfer Mills | Standard chamfered edges | High precision and durability |

| Countersink Tools | Holes requiring beveled edges | Uniform conical chamfers |

| Multi-Purpose End Mills | Small-scale chamfers or dual-purpose machining | Versatile and cost-effective |

2. Advanced CNC Technologies

- 5-Axis CNC Machining: Allows for machining of complex chamfered edges with varying angles and geometries.

- High-Speed Machining (HSM): Reduces heat buildup, ensuring smooth edges, especially on delicate materials.

- Toolpath Simulation: Modern CAM software enables toolpath simulation, reducing errors and waste.

Cost and Quality Optimization in Chamfered Edge Machining

Optimizing cost and quality in chamfered edge machining is crucial for maintaining competitiveness in manufacturing.

Strategies for Cost Optimization

Batch Processing: Group similar parts to minimize setup time and reduce costs.

Efficient Tool Usage: Invest in high-quality tools with advanced coatings to increase tool lifespan.

Material Selection: Select materials that balance machinability and application needs.

Quality Assurance Practices

- Precision Measurement: Use coordinate measuring machines (CMM) to verify chamfer dimensions.

- Regular Maintenance: Maintain CNC machines to ensure consistent performance.

Future Trends: Smart Manufacturing and Chamfered Edge Innovations

The future of chamfered edge machining is driven by advancements in automation, AI, and sustainable manufacturing practices.

AI-Driven Optimization: Real-time toolpath adjustments for enhanced efficiency.

Smart Tooling: Sensors in tools to monitor wear and performance.

Sustainable Practices: Techniques like Minimum Quantity Lubrication (MQL) reduce environmental impact while maintaining quality.

FAQ

- What is the standard angle for a chamfered edge?

The standard angle is 45°, but chamfers can be cut at other angles like 30° or 60° depending on the design requirements and application. - How does a chamfered edge differ from a beveled edge?

While both involve angled cuts, a chamfered edge typically connects two surfaces at a uniform angle, whereas a beveled edge is broader and may serve structural or aesthetic purposes. - What’s the difference between a chamfer and a fillet?

A chamfer is a flat, sloped edge, while a fillet is a rounded edge used to smooth transitions between surfaces. - Can chamfered edges be created on curved surfaces?

Yes, especially using 5-axis CNC machines, which can handle complex geometries and create chamfers on curved or irregular surfaces. - Why are chamfered edges important for mechanical components?

Chamfered edges reduce stress concentrations, prevent sharp edges that could cause injury, and facilitate easier assembly of parts. - What are the best tools for machining chamfered edges?

Chamfer mills, countersink tools, and multi-purpose end mills are commonly used, depending on the material and chamfer geometry. - How do you ensure chamfer size consistency in CNC machining?

Use precise toolpath programming, stable workholding, and regular tool inspections to maintain uniform chamfer dimensions. - What materials are suitable for chamfered edges?

Most materials, including metals (aluminum, steel, titanium), plastics, and composites, can have chamfered edges, though machining parameters vary by material. - Does a chamfer weaken or strengthen a part?

A chamfer can strengthen a part by reducing stress concentrations. It also prevents sharp edges that may crack or chip under load. - What industries rely heavily on chamfered edges?

Automotive, aerospace, electronics, construction, and medical industries frequently use chamfered edges for functional and aesthetic purposes. - What’s the difference between a chamfer and a countersink?

A chamfer is a sloped edge connecting two surfaces, while a countersink is a conical cut around a hole to accommodate screws or bolts. - How do I program a chamfer in CNC machining?

Use CAM software to define the chamfer angle, depth, and length. Codes like G01 (linear) and G02/G03 (circular) are commonly used in programming chamfers. - Can chamfered edges be polished?

Yes, chamfered edges can be polished for a smoother finish, especially for aesthetic applications like jewelry or electronic devices. - What cooling strategies are effective for chamfering hard materials?

Flood cooling and Minimum Quantity Lubrication (MQL) are effective methods for controlling heat and reducing tool wear during chamfering. - Are there alternatives to chamfering for edge finishing?

Alternatives include filleting for rounded edges or deburring for a simpler, less precise edge treatment.

Other Articles You Might Enjoy

- Chamfer in CNC Machining: A Complete Guide to Precision Edge Processing

Chapter 1: Introduction Chamfering is one of the most essential finishing operations in precision manufacturing. Over my many years working in CNC machining, I’ve discovered that a well-executed chamfer does…

- Chamfer Tool Essentials: Boost Your CNC Machining Efficiency

As I embarked on my journey in the world of CNC machining, one tool quickly became indispensable in my arsenal—the Chamfer Tool. Whether you’re a seasoned machinist or just starting…

- Choosing the Right Chamfer Bit for Optimal CNC Edge Processing

In the world of CNC machining, precision is everything. Whether you're crafting complex components for aerospace or simple fixtures for everyday use, the attention to detail can make all the…

- Countersink in CNC Machining: A Complete Guide

Understanding Countersink in CNC Machining In CNC machining, precision isn't just a feature—it's a requirement. One critical process that often gets overlooked is the countersink. A small, conical recess at the…

- Understanding Counterbore and CNC Techniques Tools and Applications

What is Counterbore and Why Does It Matter in CNC Machining? Counterbore is a term that frequently comes up in machining and manufacturing, especially in industries that require precision assembly.…

- Applications and Advantages of Bronze CNC Machining

1. Introduction: The Enduring Allure of Bronze in CNC Machining In this opening section, we explore the timeless appeal of bronze as a material for CNC machining. From its rich…

- Maximizing Precision in CNC Machining: Techniques and Tips

Importance of Precision in CNC Machining Precision is an fundamental component in the field of Computer Numerical Control (CNC) machining. It entails producing parts that are not only accurate but…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Optimizing CNC Machining Parts Using Constant Surface Speed Techniques

CNC machining, particularly on lathes, can be a complex process, but understanding and utilizing constant surface speed (CSS) techniques can simplify and enhance the efficiency of your operations. The key…