Introduction to Bronze vs Brass in CNC Machining

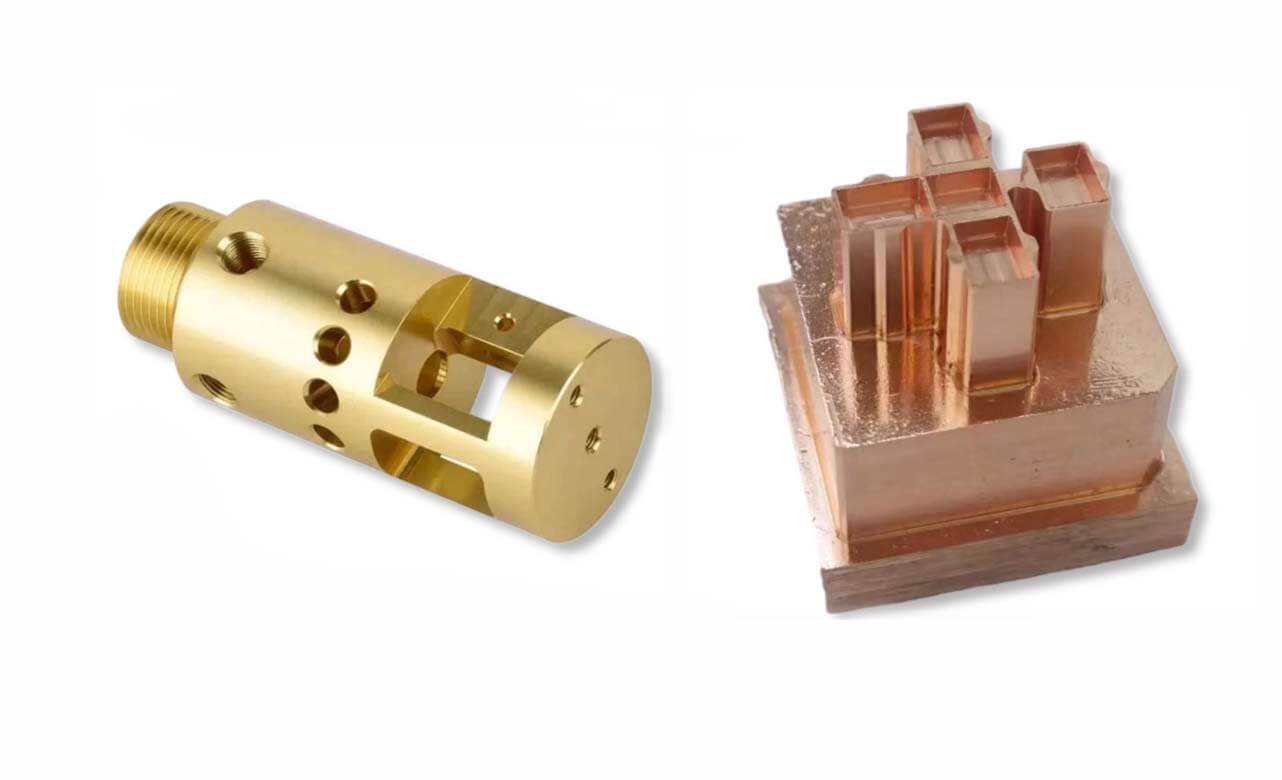

When selecting materials for CNC machining, bronze vs brass is a common comparison for machinists and designers alike. Both materials, bronze and brass, are popular in the CNC machining field due to their unique properties that serve different project requirements. Although both belong to the copper alloy family, the characteristics of bronze vs brass differ significantly due to their distinct compositions, making each material more suitable for specific CNC applications. Understanding the differences between bronze vs brass is essential for achieving optimal results in machining.

In my experience, choosing between bronze vs brass can greatly impact the quality, durability, and cost-effectiveness of a CNC project. For instance, when working with CNC-machined parts that will be exposed to high-stress environments, I often find bronze to be the ideal choice due to its strength and corrosion resistance. In contrast, for decorative CNC projects where intricate detail and aesthetic value are prioritized, brass usually offers a more cost-effective solution.

This guide provides a detailed comparison of bronze vs brass specifically for CNC applications. By examining each material’s properties, application suitability, and pros and cons, you’ll gain valuable insights into selecting the right option for your CNC project needs.

Comparative Analysis: Bronze vs Brass

A thorough comparison of bronze vs brass highlights the unique attributes that influence each material’s performance in CNC machining applications. In this section, we’ll explore the machinability, corrosion resistance, and strength of bronze vs brass to understand their best uses in CNC applications.

Machinability in Bronze vs Brass

Machinability is a key consideration when comparing bronze vs brass for CNC machining. Due to their different hardness levels, bronze vs brass behaves differently during cutting and shaping, impacting tool wear, surface finish, and overall machining efficiency.

| Property | Bronze | Brass |

|---|---|---|

| Hardness | Harder, more tool wear | Softer, less tool wear |

| Cutting Speed | Slower due to hardness | Faster, easy to machine |

| Surface Finish | Excellent after polishing | Smooth and bright |

| Ideal Applications | High-stress parts, outdoor | Decorative, intricate parts |

Bronze Machinability: When considering bronze vs brass, bronze is generally harder and therefore causes more tool wear during CNC machining. This hardness requires specialized cutting tools and slower speeds, making bronze a bit more challenging to work with. However, with the right approach, bronze can achieve a high-quality surface finish, especially after polishing, making it ideal for applications that demand both durability and an appealing finish.

Brass Machinability: In the comparison of bronze vs brass, brass stands out for its excellent machinability. Its softness allows for faster cutting speeds, reduced tool wear, and lower production costs. For CNC applications focused on decorative parts or designs requiring intricate detail, brass often proves to be a more efficient material choice.

Corrosion Resistance in Bronze vs Brass

Corrosion resistance is another critical factor in the bronze vs brass debate, especially for parts exposed to various environmental conditions. The corrosion resistance of bronze vs brass makes each suitable for distinct environments.

| Environment | Bronze Resistance | Brass Resistance |

|---|---|---|

| Humid/Marine | Excellent | Moderate |

| Acidic | Moderate | Lower |

| Industrial | Very Good | Moderate |

| Ideal Use Case | Outdoor, marine environments | Indoor, low-stress environments |

Bronze Corrosion Resistance: In the bronze vs brass comparison, bronze has superior corrosion resistance, particularly in marine or humid environments. This makes bronze highly suitable for outdoor applications, as its composition with tin helps prevent rusting. For CNC projects involving outdoor sculptures or marine equipment, bronze remains the material of choice due to its long-lasting resilience.

Brass Corrosion Resistance: In the bronze vs brass context, brass offers moderate corrosion resistance, making it ideal for indoor applications. While brass can tarnish over time, it is widely used in decorative and indoor environments where humidity is not a major concern.

Cost and Application Suitability in Bronze vs Brass

Cost is a pivotal factor in choosing bronze vs brass for CNC applications, especially when balancing material performance with budget considerations. Both bronze and brass have distinct cost implications that impact their application suitability in CNC projects.

| Property | Bronze | Brass |

|---|---|---|

| Raw Material Cost | Higher | Lower |

| CNC Tool Wear | Higher due to hardness | Lower due to softness |

| Machining Time | Longer, slower cutting speeds | Shorter, faster cutting speeds |

| Ideal Applications | High-strength, corrosion-resistant | Decorative, budget-sensitive |

Bronze Cost and Suitability: In comparing bronze vs brass for cost-effectiveness, bronze tends to have a higher raw material cost. Its superior durability and corrosion resistance often justify this cost in CNC projects where long-term performance is essential. However, bronze’s hardness can lead to greater CNC tool wear and longer machining times, which adds to production expenses. Despite these factors, when CNC machining components for high-stress or outdoor applications, bronze’s benefits outweigh its costs, especially in marine or heavy-duty settings. For projects that demand strength and longevity, bronze remains a sound investment over time.

Brass Cost and Suitability: On the other hand, bronze vs brass cost analysis often favors brass for budget-conscious projects. Brass’s softer nature leads to lower tool wear, faster cutting speeds, and reduced machining costs, making it ideal for decorative applications or parts that don’t require extreme durability. Brass’s affordability and machinability make it a popular choice for CNC machinists, especially in the design of interior fixtures, decorative hardware, and plumbing elements. For applications that prioritize aesthetics and efficiency, brass provides an economical and visually appealing option.

Visual and Aesthetic Considerations in Bronze vs Brass

The visual characteristics of bronze vs brass play a crucial role in material selection, particularly in applications where appearance is a primary concern. Each metal offers a distinct aesthetic, making both bronze and brass highly desirable in decorative and architectural CNC applications.

| Property | Bronze Appearance | Brass Appearance |

|---|---|---|

| Initial Color | Reddish-brown | Golden-yellow |

| Aging/Patina | Darkens, develops greenish tint | Retains color, may tarnish |

| Aesthetic Applications | Vintage, rustic aesthetics | Elegant, polished finishes |

Bronze Aesthetic: In the bronze vs brass debate regarding appearance, bronze’s warm reddish-brown color and natural patina development give it a timeless, rustic look. Over time, bronze develops a darker patina, often with green hues when exposed to the elements, adding to its vintage appeal. This aging process enhances bronze’s durability, as the patina serves as a protective layer against further corrosion. Bronze’s aesthetic qualities make it a popular choice in CNC-machined sculptures, outdoor installations, and antique-style architectural features. For projects that benefit from a classic look, bronze offers a distinctive and durable finish that ages gracefully.

Brass Aesthetic: Brass, with its bright golden-yellow hue, provides a more polished and refined look, making it highly sought-after for decorative CNC applications. In the bronze vs brass comparison, brass stands out for its ability to retain its color and luster over time, especially with minimal tarnishing indoors. Brass is frequently chosen for interior design elements, plumbing fixtures, and decorative hardware, where its elegant appearance adds value to the design. CNC machinists can achieve high levels of detail and polish with brass, creating parts that blend aesthetic appeal with ease of production.

Industry Case Studies in Bronze vs Brass Applications

Examining real-world applications of bronze vs brass in different industries reveals why specific sectors prefer one material over the other. The following case studies demonstrate how unique attributes of bronze vs brass align with various project requirements in CNC machining.

Case Study 1: Marine Industry – Bronze vs Brass

- Application: Propeller shafts and marine fittings

- Material Choice: Bronze

- Reasoning: When comparing bronze vs brass for marine applications, bronze is favored for its corrosion resistance and strength, essential in saltwater environments. Bronze’s durability justified the higher cost, as it extended the lifespan of the marine components, reducing maintenance needs.

Case Study 2: Interior Design and Furniture – Bronze vs Brass

- Application: Decorative handles and hardware accents

- Material Choice: Brass

- Reasoning: In the bronze vs brass choice for interior design, brass’s golden appearance and lower cost made it ideal for decorative fixtures. Its excellent machinability allowed the designer to create intricate, polished handles that met both aesthetic and budget goals. Brass’s smooth surface also provided a high-quality finish with minimal post-processing, an advantage in detailed CNC designs.

Case Study 3: Heavy-Duty Industrial Parts – Bronze vs Brass

- Application: Bearings and bushings in industrial machinery

- Material Choice: Bronze

- Reasoning: When choosing bronze vs brass for industrial parts, bronze’s superior tensile strength and wear resistance made it the preferred material. These qualities ensured that the components could withstand heavy loads and continuous movement without significant wear, making bronze a cost-effective choice over time for high-stress applications.

Case Study 4: Artistic Sculptures – Bronze vs Brass

- Application: Outdoor statues and installations

- Material Choice: Bronze

- Reasoning: In the realm of bronze vs brass for outdoor sculptures, bronze’s patina development and weather resistance provided a timeless look that suited the artistic intent. Bronze’s aging process added character to the artwork while protecting it from environmental damage, making it ideal for public installations designed to endure over time.

Case Study 5: Plumbing Fixtures – Bronze vs Brass

- Application: Faucets, pipe fittings, and valves

- Material Choice: Brass

- Reasoning: In the bronze vs brass comparison for plumbing applications, brass was selected for its corrosion resistance in indoor settings and its visual appeal. Brass’s ease of machining and affordability allowed for the production of detailed, functional plumbing fixtures that also met aesthetic standards, making it a popular choice in residential and commercial plumbing.

Conclusion: Choosing Between Bronze vs Brass

The bronze vs brass decision for CNC applications ultimately depends on a project’s specific needs, such as durability, appearance, cost, and environmental suitability. For CNC machining projects that prioritize strength, corrosion resistance, and long-term durability, bronze is often the better choice, especially in industrial, marine, or heavy-duty applications. Conversely, brass offers a cost-effective, aesthetically appealing solution for decorative applications, interior design elements, and components where machinability and visual appeal are more important than extreme durability.

Throughout my CNC machining experience, I’ve observed that choosing between bronze vs brass requires balancing practical and aesthetic considerations. With the insights provided in this guide, CNC machinists and designers alike can make informed choices that enhance the quality and appeal of their projects.

FAQ about Bronze vs Brass

- Which is easier to machine, bronze or brass?

Brass is generally easier to machine due to its ductility and lower tool wear, making it the preferred choice in the bronze vs brass comparison for ease of CNC machining. - Is coolant necessary when CNC machining bronze or brass?

Yes, especially with bronze. Coolant helps reduce tool wear and overheating, particularly for the harder material in this bronze vs brass comparison. - What are the main components of bronze and brass?

Bronze is primarily composed of copper and tin, while brass is mainly copper and zinc. These differences are central to understanding the bronze vs brass comparison in terms of performance and application. - How do bronze and brass compare in terms of corrosion resistance?

In the bronze vs brass comparison, bronze offers superior corrosion resistance, especially in marine environments. Brass, while decent, is more suited to indoor or low-humidity applications. - Which material is better for decorative CNC machining?

Brass is often better for decorative applications in the bronze vs brass debate due to its golden color and smooth finish, which is ideal for interior and ornamental uses. - Is the cutting speed higher for brass than for bronze in CNC machining?

Yes, in most bronze vs brass comparisons, brass allows for faster cutting speeds due to its softer nature, while bronze requires slower speeds. - What is the cost difference between bronze and brass?

Brass is generally more affordable than bronze, which impacts decisions in bronze vs brass selection for budget-sensitive projects. - How can I decide if my project needs bronze or brass?

For high-strength, corrosion-resistant needs, bronze is recommended. For decorative or cost-effective applications, brass is often the better choice, as highlighted in this bronze vs brass comparison. - Can both bronze and brass be machined to tight tolerances with CNC?

Yes, but in the bronze vs brass comparison, bronze may require more precise tooling due to its hardness, while brass is easier to machine accurately. - Is brass suitable for high-load mechanical components?

Brass is less suited for high-load applications compared to bronze, which excels in strength and wear resistance in this bronze vs brass comparison.

Other Articles You Might Enjoy

- Applications and Advantages of Bronze CNC Machining

1. Introduction: The Enduring Allure of Bronze in CNC Machining In this opening section, we explore the timeless appeal of bronze as a material for CNC machining. From its rich…

- Brass vs. Bronze: Unveiling the Superior Metal for CNC Machining

Introduction CNC machining stands for Computer Numerical Control machining, a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This technique is pivotal for creating…

- Brass vs. Bronze in CNC Machining: Which Offers Better Precision and Durability?

CNC Machining and Material Selection CNC (Computer Numerical Control) machining is a digitally automated process used in manufacturing sectors where computers control machine tools. This intricate technology enables high precision,…

- Bronze vs. Brass in CNC Machining: Properties, Uses, and Selection Criteria

Introduction to CNC Machining and Importance of Metals CNC machining, or Computer Numeric Control machining, is a commonly utilized method in the manufacturing sector that involves the use of computers…

- Bronze vs. Aluminum in CNC Machining: Which Offers Better Precision?

Introduction to CNC Machining and Commonly Used Materials CNC machining is an indispensable part of modern manufacturing processes, being a widespread method by which digital design data directs the operation…

- Global Metal Material Standards Comparison Table for CNC Machining

In the world of precision manufacturing, CNC machining plays a pivotal role across various industries, from aerospace and automotive to medical devices and consumer electronics. One of the key elements in CNC…