Introduction

When it comes to precision in manufacturing, particularly in industries where durability and heat resistance are paramount, ceramic materials often take center stage. Whether it’s aerospace, medical devices, or specialized machinery, the demand for high-quality ceramic components is growing. However, machining ceramics is not without its challenges. This is where CNC machined parts, paired with advanced milling techniques using diamond-coated tools, become crucial. This article explores the intricacies of ceramic milling, focusing on how diamond-coated tools can significantly enhance the precision and efficiency of producing CNC machined parts.

Understanding Ceramic Materials in CNC Machining

Ceramics, known for their hardness and brittleness, pose unique challenges in CNC machining. Unlike metals, ceramics do not deform plastically; instead, they tend to fracture when subjected to stress. This makes the traditional cutting and milling processes more complex. Common ceramic materials used in CNC machined parts include alumina (Al2O3), zirconia (ZrO2), and silicon carbide (SiC). Each of these materials requires a specific approach to machining to maintain the integrity of the final product.

1. Alumina (Al2O3):

Alumina is widely used in CNC machining due to its high hardness, excellent thermal stability, and resistance to wear. It is commonly found in electrical insulators, cutting tools, and biomedical implants.

2. Zirconia (ZrO2):

Zirconia is preferred for its exceptional toughness and resistance to cracking. It is often used in dental implants, automotive components, and knife blades.

3. Silicon Carbide (SiC):

SiC is known for its high thermal conductivity and strength at elevated temperatures. It is commonly used in mechanical seals, semiconductor devices, and heat exchangers.

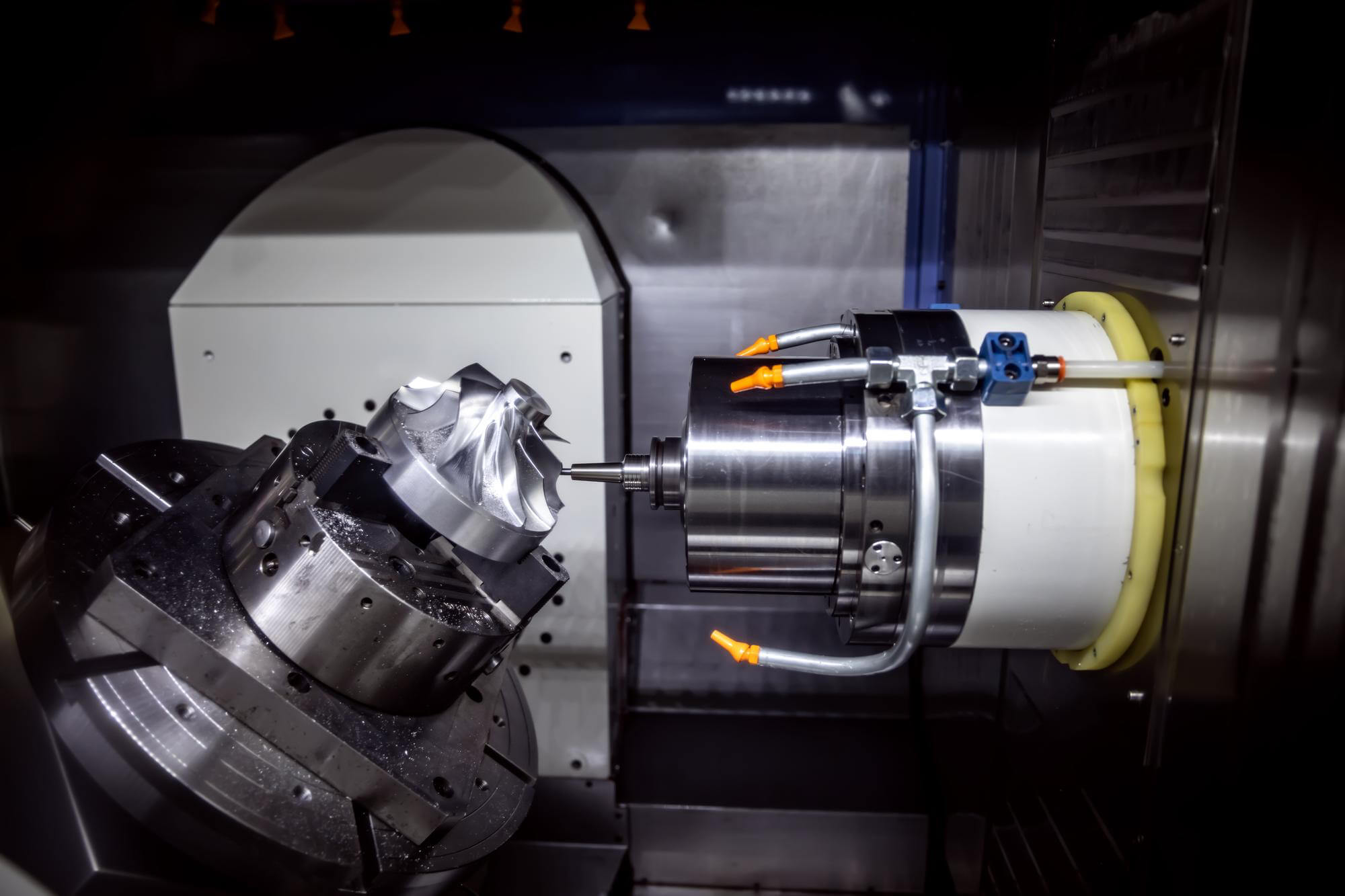

The Role of Diamond-Coated Tools in Ceramic Milling

Diamond-coated tools are essential in machining ceramics because of their superior hardness, which allows them to cut through tough ceramic materials with minimal wear. The diamond coating enhances the tool’s durability, enabling it to maintain sharpness and precision over extended periods.

Advantages of Diamond-Coated Tools:

- High Wear Resistance: The hardness of diamond reduces tool wear, leading to longer tool life and consistent performance.

- Improved Surface Finish: Diamond-coated tools produce smoother surfaces, reducing the need for post-machining polishing.

- Increased Cutting Efficiency: These tools allow for higher cutting speeds and feed rates, improving overall productivity.

Techniques for Precision Ceramic Milling

Precision in ceramic milling requires a thorough understanding of the material properties and the correct application of tools and techniques. Below are some key strategies for achieving optimal results when milling ceramic CNC machined parts.

1. Optimizing Cutting Parameters

Selecting the right cutting parameters is crucial in ceramic milling. This includes the cutting speed, feed rate, and depth of cut. Ceramic materials are sensitive to cutting forces, so it’s essential to balance these parameters to avoid excessive tool wear and material damage.

| Cutting Parameter | Recommended Range for Ceramics | Impact on Milling |

|---|---|---|

| Cutting Speed | 200-500 m/min | Affects surface finish and tool wear |

| Feed Rate | 0.02-0.1 mm/rev | Influences chip removal and tool life |

| Depth of Cut | 0.1-0.5 mm | Controls material removal rate and surface integrity |

2. Toolpath Strategy

The toolpath strategy plays a significant role in minimizing stress on the ceramic material. Climb milling is often preferred over conventional milling because it reduces the cutting force and the likelihood of chipping or fracturing the ceramic part.

3. Cooling and Lubrication

While ceramics have low thermal conductivity, excessive heat can still lead to cracks or microfractures in the material. Proper cooling and lubrication are essential to manage the heat generated during milling. A mist or air blast can be effective, though in some cases, a coolant may be required.

4. Multi-Pass Milling

Instead of trying to remove large amounts of material in a single pass, multi-pass milling allows for more precise control over the machining process. This method reduces the risk of material fracture and ensures a smoother surface finish.

Challenges in Ceramic Milling and How to Overcome Them

Despite the advantages of using diamond-coated tools, machining ceramics still presents challenges. Understanding these challenges and how to mitigate them is key to successful ceramic milling.

1. Tool Wear and Replacement

Even with diamond coatings, tool wear is inevitable, especially when machining highly abrasive ceramics like silicon carbide. Regular inspection and timely replacement of tools are necessary to maintain precision.

2. Material Chipping

Chipping is a common issue in ceramic milling, particularly at the edges of the machined part. Using the correct toolpath strategy, reducing the depth of cut, and ensuring proper tool sharpness can help minimize chipping.

3. Surface Roughness

Achieving a smooth surface finish is critical in many applications of CNC machined parts. Adjusting the feed rate and cutting speed, along with using fine-grit diamond tools, can significantly improve surface quality.

Case Studies: Real-World Applications of Ceramic Milling

To illustrate the effectiveness of precision ceramic milling with diamond-coated tools, let’s look at a couple of real-world applications.

Case Study 1: Aerospace Components

In the aerospace industry, ceramic materials are often used for their high-temperature resistance and lightweight properties. Milling turbine blades made from zirconia requires extreme precision to ensure they withstand the harsh operating conditions. Using diamond-coated tools, manufacturers achieved a surface finish of less than 0.5 microns, reducing the need for post-machining polishing and improving the overall efficiency of the production process.

Case Study 2: Medical Implants

Ceramic materials like alumina and zirconia are frequently used in medical implants due to their biocompatibility and wear resistance. In manufacturing hip joint replacements, precision milling with diamond-coated tools ensures a perfect fit and smooth surface, crucial for the longevity and comfort of the implant.

Future Trends in Ceramic Milling

As the demand for CNC machined parts made from ceramic materials grows, the technology and techniques used in milling these materials continue to evolve. Future trends include:

1. Advanced Tool Coatings: Beyond diamond coatings, researchers are exploring nanocomposite coatings that could offer even greater wear resistance and thermal stability.

2. Automation in Milling: The integration of AI and machine learning in CNC machining could lead to more efficient and precise milling processes, particularly in complex geometries and materials like ceramics.

3. Hybrid Machining Techniques: Combining traditional milling with other processes like laser ablation could further enhance the precision and efficiency of ceramic machining.

Conclusion

Ceramic materials, with their exceptional properties, are integral to many high-performance applications. However, their hardness and brittleness make them challenging to machine. By leveraging the capabilities of diamond-coated tools in CNC machining, manufacturers can achieve the precision, efficiency, and surface finish required for these demanding applications. As technology advances, the future of ceramic milling promises even greater possibilities, ensuring that CNC machined parts continue to meet the highest standards in industries such as aerospace, medical, and beyond.

Other Articles You Might Enjoy

- Mastering Cavity Milling Techniques for CNC Machined Parts

Cavity milling is a common operation in CNC machining centers. It involves removing material from a closed area defined by its boundary lines, which can include sidewalls and a bottom…

- From Tools to Coatings Efficient Milling Strategies for Composite CNC Machined Parts

Composite materials like Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP) have revolutionized industries such as aerospace, automotive, and marine. Their unique combination of strength, light weight,…

- Unraveling the World of CNC Machined Plastic Parts(CNC machined plastic parts Mabel)

Modern innovations have taken traditional manufacturing methods to new heights. One such innovation that stands out is Computer Numerical Control (CNC) machining, a process used extensively in various industries from…

- CNC Machined Plastic Parts: An In-depth Overview(CNC machined plastic parts Norman)

Computer Numeric Control (CNC) machining is an advanced manufacturing process where pre-programmed software dictates the movement of factory machinery and tools. These applications can carry out complicated manufacturing tasks with…

- Enhancing CNC Machining with Smart Alloys: Shape Memory Metals vs. Traditional Alloys

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated shaping of materials. This technology relies heavily on the…

- CNC Machined Parts Mastering Advanced Ceramic Machining Techniques

In the realm of CNC machining, ceramics represent a significant challenge and opportunity. Their extraordinary properties, such as high hardness, wear resistance, and thermal stability, make them ideal for high-performance…