Online CNC Machining Service For Custom Parts

As an excellent method for custom machining, one-stop online CNC machining services to speed up your product development cycle from protopye to production parts. Get your free quote today!

- Instant Quote

- Fast Turnaround

- Pay After Delivery

- All uploads are secure and confidential

Premium Machining Service Trusted by

Get Your CNC Machined Parts Online Easily

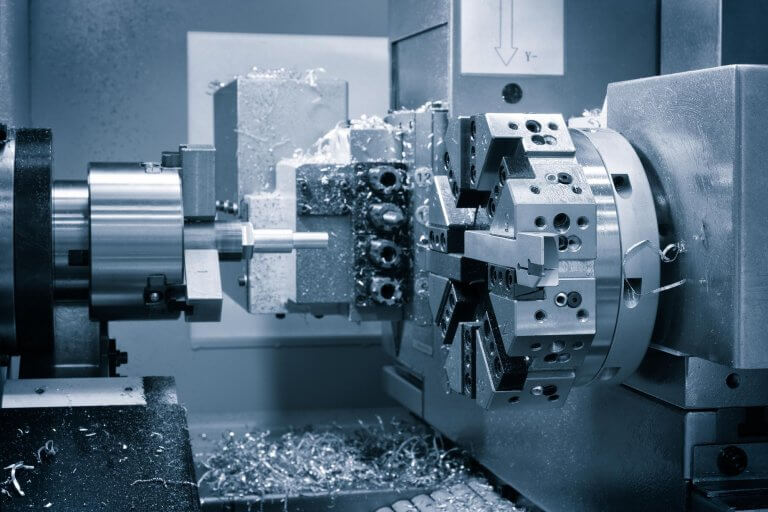

With our hundred sets of CNC machines featuring from 3 to 5-axis, we offer fast CNC machining service to our worldwide customers. Together with our full range of material suppliers, surface finish experts, and well-trained technical support, our customers can source high-quality custom machined parts in the shortest time possible. We specialize in delivering CNC machined parts that meet exact specifications, ensuring precision for every project. For those exploring Prototype Manufacturing, our advanced CNC capabilities allow us to quickly turn concepts into tangible prototypes. This makes us a top choice for both production runs and initial design testing. If you are looking for precision CNC machining service online, Want.net will be your best bet. Click the button below to get a quote now!

Our CNC Machining Service Capabilities

CNC machining service at Want.net provides excellent turning and milling capabilities. We offer instant quotes for CNC machined parts for both small and large-scale manufacturing. To get an online quotation for a CNC machining part, simply send us a drawing with material choice and surface roughness, and we shall respond to your request immediately.

CNC Milling Service

We are ready to provide CNC milling services for a range of applications and materials. Our CNC milling machines can work with the most popular materials, including composites, aluminum, steel, brass, plastics, and polymers with very tight tolerances.

Get a free online CNC quote from us immediately for your CNC milling project.

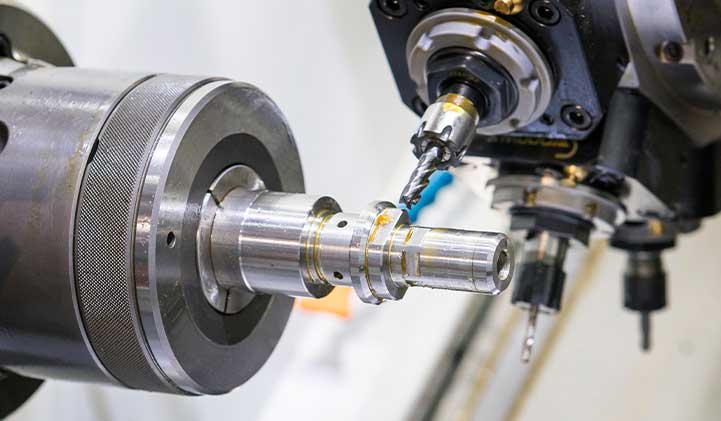

CNC Turning Service

We provide high-precision CNC turning services meeting requirements for a wide variety of applications, such as automotive, aerospace, medical, and industrial.

Thanks to our state-of-the-art machining technology, we have high tech-CNC machine, seasoned machinists, and committed customer service.

3-5 Axis Machining

Custom metal parts with flat surfaces are produced using 3-axis machining, while components with highly curved geometries are produced using 5-axis machining.

Surface finishing techniques including grinding, polishing, and deburring are also available as part of CNC machining services.

Carrying the highest standard in CNC machining, we aim to provide quick CNC machined parts at the lowest possible price with a faster turnaround. Since we have comprehensive CNC machining capabilities, you can order CNC machining parts online. For this purpose, we provide a quick quotation option available on our website where you can drop your query. Our team ensures to reply to every request in the minimum possible time.

Huajian - CEO of Want.net

Get Advantage From Factory-Direct Pricing Today!

Discover The Amazing World Of CNC Machining

Want.Net specializes in CNC machining using the turning and milling processes. We work with an extensive network of suppliers to cover your requirements as completely as possible.

CNC stands for Computerized Numerical Control. It’s a technology that allows a computer to control machine tools during manufacturing. This makes it possible to produce complex parts made from various materials like metal and plastic cost-effectively and efficiently. CNC machined parts are used in various industries, such as automotive, aerospace, and industrial engineering. With the versatility of this technology, the possibilities for implementation are vast.

Why Choose Our Online CNC Machining Service

CNC Machining Material

Aluminum 6061

Aluminum 5052

Aluminum 2024

Aluminum 6063

Aluminum 7050

Aluminum 7075

Aluminum MIC-6

Nitronic 60 (218 SS)

Stainless Steel 15-5

Stainless Steel 17-4

Stainless Steel 18-8

Stainless Steel 303

Stainless Steel 316/316L

Stainless Steel 416

Stainless Steel 410

Stainless Steel 420

Stainless Steel 440C

Titanium (Grade 2)

Titanium (Grade 5)

Learn about Titanium

Zinc

Learn about Zine

If you can’t find what you are looking for, we are still able to source additional alloys and tempers from within our material supplier network. Just tell us what you need and we will send you a custom quote within 1 day.

High-strength engineering plastic used for many commercial products.

Learn More

A clear glass-like plastic. Good wear and tear properties. Great for outdoor use.

Learn More

Resin with good moisture resistance, high wear-resistance, and low friction.

Learn More

Constructed of an epoxy resin with fiberglass fabric reinforcement, and also called epoxy-grade industrial laminate and phenolic, this material offers high strength and low moisture absorption.

High-density polyethylene is a moisture and chemical-resistant plastic with good impact strength. The material is outstanding for outdoor applications as well as watertight containers or seals.

Learn More

Offers increased mechanical strength, rigidity, good stability under heat and/or chemical resistance.

Learn More

With almost twice the tensile strength of ABS, polycarbonate has superior mechanical and structural properties. Used widely in automotive, aerospace, and other applications that require durability and stability.

Learn More

Offering excellent tensile strength, PEEK is often used as a lightweight substitute for metal parts in high-temperature, high-stress applications. PEEK resists chemicals, wear, and moisture.

Has excellent electrical properties and little or no moisture absorption. It carries light loads for a long period in widely varying temperatures. It can be machined into parts requiring chemical or corrosion resistance.

This material surpasses most plastics when it comes to chemical resistance and performance in extreme temperatures. It resists most solvents and is an excellent electrical insulator.

Ultra-high molecular weight polyethylene. A general-purpose material. It offers a unique combination of wear and corrosion resistance, low surface friction, high impact strength, highchemical resistance, and does not absorb moisture.

Polyvinyl chloride (Type 1) is a highly chemical-resistant synthetic plastic, PVC is commonly in environments exposed to liquids or requires electrical insulation.

Learn More

High-performance composite material used for advanced engineering applications.

Lightweight and high-strength material used for diverse industrial and aerospace applications.

Durable and cost-effective material used for construction and automotive applications.

Lightweight and impact-resistant material used for defense and protective gear applications.

Learn More

High-strength and wear-resistant material used for aerospace and automotive components. chemical-resistant plastic with good impact strength. The material is outstanding for outdoor applications as well as watertight containers or seals.

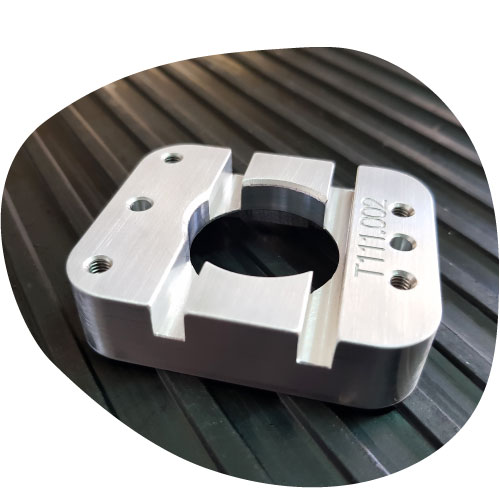

From CNC Prototyping to End-Use Production

CNC rapid prototyping is a manufacturing technique that uses computer-controlled machines to produce items with greater precision and repeatability in a minimum time. This technology is frequently used to create low-volume parts with complicated geometries that might be difficult to create using traditional methods.

At Want.net, customers can access the most versatile rapid prototype machining shop where they can order prototyped CNC machining parts with our online quoting system with faster lead time.

Rapid Prototyping

With our cost-effective and fast production of prototypes, you can quickly turn your idea into reality no matter you need a full-function or display prototype.

There are many things you can check on a prototype before going into production. Take the chance and put your ideas to the test and find the small mistakes and optimization potentials that will make your product even better afterwards!

Bridge Production

Low-volume runs of the part or products will be produced during this step using CNC machining or 3D printing. Bridge production will allow you to:

- Reduce the risk of design error

- Tweak designs and try different iterations of your products

- Test the market before investment in mass production

Mass Production

With all the savings and benefits from bridge production and the attention gained from prototyping and presales, it's time to enter mass production. In this step, we will produce your order on a large scale. Our high automation and optimized production process can ensure the unit prices are still very low.

What is CNC Machining?

CNC machining, short for Computer Numerical Control machining, is a sophisticated manufacturing process that utilizes computerized automation to produce precise and intricate parts. It involves the use of computer-controlled machines and tools to shape and cut materials according to programmed specifications.

At its core, CNC machining relies on a combination of software, computer-aided design (CAD), and computer-aided manufacturing (CAM) to generate the necessary instructions for the machines. These instructions, typically written in G-code, dictate the precise movements and actions of the tools, workpiece, and other machine components.

CNC machining offers several advantages over traditional manual machining methods. It provides greater accuracy, repeatability, and efficiency, allowing for the creation of complex geometries and intricate details that would be challenging or impossible to achieve manually.

Additionally, CNC machining reduces the need for extensive manual labor, as human operators focus on programming and overseeing the process.

Types of CNC Machining

CNC machining encompasses various processes, including CNC milling, CNC turning, CNC drilling,CNC grinding…….

CNC Milling

The CNC milling process utilizes milling machines equipped with rotating cutting tools. These machines can move along multiple axes, enabling the creation of intricate shapes and profiles. CNC mills are ideal for producing cnc machined parts with complex geometries, such as prototypes, molds, and precision parts. They play a significant role in subtractive manufacturing, where material is gradually removed to shape the final product.

CNC Turning

Also known as lathe machining, CNC turning involves rotating a workpiece while cutting tools shape the part. The workpiece spins, while the cutting tool moves linearly to create the desired shape. CNC turning is commonly used for cylindrical components like shafts, pins, and fittings. It is another crucial aspect of the subtractive manufacturing process.

Electrical Discharge Machining (EDM)

Electrical discharge machining employs electrical discharges to precisely erode the material and create intricate cuts. This technique is particularly beneficial for machining hard materials and intricate designs that may pose challenges with other methods. EDM machines find applications in industries such as aerospace, tooling, and mold making.

These diverse CNC machining processes enable the production of custom CNC parts through a subtractive manufacturing process. By carefully removing material, CNC mills, CNC turning, and EDM machines can transform raw materials into highly accurate and intricate components. This precise manufacturing approach empowers industries to create complex parts with exceptional accuracy and reliability.

Applications of CNC Machining

CNC machining finds applications across a wide range of industries and sectors. Notable examples include aerospace, automotive, medical, electronics, and prototyping and rapid manufacturing. In the aerospace industry, CNC machining plays a crucial role in manufacturing aircraft components such as engine parts, turbine blades, and structural elements. The automotive industry extensively utilizes CNC machining for producing engine components, transmission parts, brake system components, and customized automotive accessories. In the medical field, CNC machining enables the production of precise and intricate medical devices, implants, prosthetics, and surgical instruments. The electronics industry relies on CNC machining to manufacture circuit boards, connectors, enclosures, and various electronic components. Additionally, CNC machining is instrumental in rapid prototyping and low-volume production, allowing for quick design iterations and cost-effective manufacturing. These diverse applications demonstrate the versatility and significance of CNC machining in modern industries.

Online CNC Machining Services

Online CNC machining services empower businesses to streamline their manufacturing processes, reduce costs, and accelerate product development. Whether you require one-off prototypes, low-volume production, or customized parts, the convenience and efficiency of online services make CNC machining accessible and beneficial for a wide range of applications.

More Knowledge about cnc machining

What is Grinding: Definition, Methods & Applications?

The Concept and History of Grinding Technology Introduction Grinding is one of the most critical processes in modern manufacturing, especially for achieving high levels of

What is CNC Drilling: Types, Process & Key Techniques?

What is CNC Drilling Technology? CNC (Computer Numerical Control) drilling is a precise and automated manufacturing process used to create holes in various materials with

What is CNC Turning: Definition, Process & Applications

What is CNC Turning Technology? CNC (Computer Numerical Control) turning is a machining process where a cutting tool, typically a non-rotary tool bit, removes material

What is CNC Milling: Types, Processes & Benefits

What is CNC Milling? How Does it Differ from Traditional Milling? Milling is one of the most versatile machining processes used to manufacture parts with

CNC Machining FAQs

The cost of your CNC machining project depends on some factors such as the design, tolerance require, material, machining times, and human resources that have to be input into the project. You can send us your CAD file so we can prepare the quote for you.

- Select The Right Machining Process: One of the best techniques to reduce the cost f CNC machining is to choose an efficient machining process. Generally, you need a professional machining company that will guide you through the complete CNC machining cost-reduction process.

- Refine The Design of The Part: If you have a perfect design for the CNC machining part, it can significantly reduce machining costs.

- Right Tooling Reduces The Cost: Generally, traditional machining centers have manual tooling which increases the cost of the metal part. Find the best CNC machining company near you with the latest CNC machining equipment.

We can accommodate the prototyping and production of large machined parts, plastic or metal. Our maximum CNC machining build envelope is 2000 mm x 1500 mm x 300 mm — suitable even for large-scale furniture and architectural components.

If you want to start CNC machining parts production with Want.net, the process is quite convenient. Get in touch with us by clicking the Instant Quote button.

We follow the highest standards for manufacturing custom CNC machined parts. Since we have the latest CNC milling and turning equipment, you can drop your order in both small and bulk quantities.

Yes, we provide 5 Axis CNC machining solutions for metal parts with complex geometry and high precision standards. We offer our services for a range of materials with precise tolerances, curved surfaces, and fine detailing. Additionally, we provide post-processing services like plating, powder coating, and anodizing.

In a traditional machining shop, accuracy and precision are the biggest problems. Similarly, they follow traditional tooling methods which lack precision. Want.net ensures the highest manufacturing standards and has the industry’s leading CNC machining equipment along with expert operators.

Down to 0.001mm.

Put Your Machined Parts into Production Today!

You’re one-step away from the most affordable CNC machining service. Fill the form beside and we will get back to you within 24 hours.

GET QUICK QUOTE

- All uploads are secure and confidential