Understanding CNC Machining

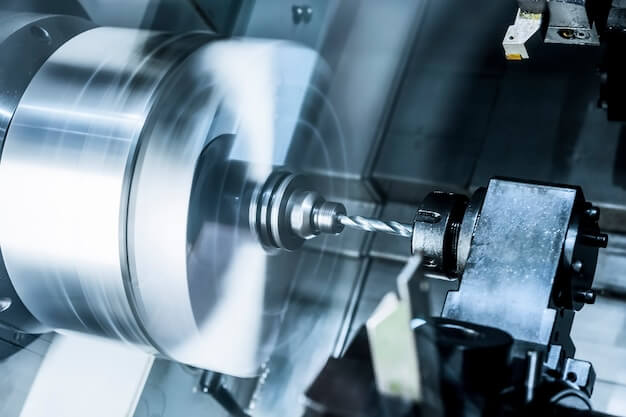

In manufacturing, Computer Numerical Control (CNC) machining is a crucial method that enables high precision and efficiency through automated control of machine tools. Its significance rests on its ability to produce complicated parts with limited human intervention, thereby increasing productivity while reducing errors and production time. When it comes to specialized applications —each material has specific characteristics that make it suitable for a particular application— choosing the right metal, such as beryllium copper or tantalum, is vital.

- Beryllium Copper: Known for its excellent thermal conductivity, electrical resistivity and high strength, this alloy is commonly utilized in electronic connectors and hard drive components due to its nonmagnetic nature.

- Tantalum: This rare, hard, blue-gray metal is highly resistant to corrosion and wear, making it ideal for capacitors in power supply applications, surgical implants, and aircraft engines.

Selecting the correct material can have a huge impact on the durability, functionality, and longevity of the end product. Hence, understanding the distinctive properties of each material becomes imperative for manufacturers to ensure optimal performance.

Overview of Rare Metals: Beryllium Copper and Tantalum

Rare metals are indispensable for manufacturing, particularly in industries that require the utmost precision, durability, and specialized features. Two such metals, beryllium copper and tantalum, stand out for their unique characteristics.

Beryllium copper is renowned for its beneficial attributes, allowing it a multitude of applications across different sectors. The key traits of this alloy include high strength, non-magnetic nature, excellent heat dissipation, resistance to wear and tear, good electrical conductivity, and flexibility. Therefore, it serves significantly in fields like automotive, aerospace, defense systems, telecommunication equipment, among others, where these attributes contribute to superior performance.

Tantalum on the other hand, carries vital features making it an optimal choice for many specialized usages. This rare metal scores high on ductility, melting point, corrosion resistance, biological compatibility, and capacitance. These properties make it valuable for a wide range of products, from mobile phones and computers to cutting-edge medical devices and chemical processing equipment. With these exceptional properties, both beryllium copper and tantalum play integral roles in meeting the demanding requirements of modern technology and manufacturing.

Application of Beryllium Copper in CNC Machining

When considering the application of beryllium copper in CNC machining, it is important to take into account its properties such as high strength, conductivity, and corrosion resistance. Beryllium copper is commonly used in specialized applications where these properties are crucial, such as in aerospace, automotive, and electronic industries.

Role of Tantalum in CNC Machining Industry

Tantalum, a refractory metal known for its incredible versatility and reliability, possesses a vital role within the computer numerical control (CNC) machining industry. This is primarily due to its exceptional properties which include high melting point, excellent corrosion resistance, and remarkable ability to conduct electricity and heat. Tantalum’s capacity to withstand harsh environmental conditions makes it an indispensable asset specifically in industrial scenarios such as aerospace and military applications. For instance, in the production of jet engines, tantalum is employed owing to its resistance to extreme temperatures, thereby offering increased engine efficiency and longevity.

Beryllium Copper vs. Tantalum in Specialized Applications

Direct comparison between beryllium copper and tantalum reveals distinct differences that bear significance in specialized applications. Beryllium copper earns a high score for strength, rivalling even steel and maintaining this attribute at elevated temperatures. On the other hand, tantalum is not as strong but offers unrivalled malleability which makes it highly shapeable. When it comes to resistance to corrosion, both tantalum and beryllium copper excel. However, tantalum outperforms most metals with its exceptional corrosion resistance even against potent acids like nitric and sulfuric acid.

- Regarding conductive capabilities, beryllium copper stands tall exhibiting excellent electrical conductivity.

- In terms of suitability based on the nature of application:

- Beryllium copper finds extensive use in parts requiring high reliability under stress such as springs, connectors and contacts in electronics due to its resilience and conductivity.

- Tantalum, owing to its malleability and corrosion resistance, serves perfectly in chemical processing equipment and surgical implants.

Making the Right Material Choice: Beryllium Copper vs. Tantalum

In the arena of CNC Machining, selecting the correct material is crucial for achieving desired results in specialized applications. Being aware of the main differences between beryllium copper and tantalum is the first step towards making an informed decision. Beryllium copper stands out due to its impressive strength, high conductivity, excellent formability, and resistance to stress relaxation. On the other hand, tantalum is admired for its extreme density, corrosion resistance, and exceptional ability to withstand high temperatures and pressures.

- Beryllium Copper: Excellent in strength, conductivity, formability, and resistance to stress relaxation.

- Tantalum: Known for extreme density, corrosion resistance, withstanding high temperatures and pressures.

Your understanding of these properties and how they apply to your specific project requirements could be pivotal when choosing a suitable material for precision metal parts. Accurate knowledge about the qualities and performance characteristics of both metals will aid not only in meandering through technical selection but also in optimizing cost-efficiency and ensuring long-term durability of machined components.

Understanding Beryllium Copper and Tantalum in CNC Machining

In the realm of Computer Numerical Control (CNC) machining, two particular metals stand out due to their unique properties: Beryllium Copper and Tantalum. These may not be common household names, but they play critical roles in various industries for specialized applications. Simply put, Beryllium Copper is a type of metallic alloy that marries the strength of steel with the conductivity of copper while Tantalum is a rare metal known for its exceptional resistance to corrosion and extreme temperature tolerance.

- Beryllium Copper: Characterized by high strength and excellent electrical and thermal conductivity, it’s commonly used in situations demanding low spark risk (like explosive environments) or non-magnetic requirements (such as electronics industry).

- Tantalum: Known for its ability to withstand extreme conditions without corroding, making it ideal for uses in chemical processes or high-temperature applications like aerospace or nuclear sectors.

The choice between these two materials hinges on several factors; including the specific demands of an application, cost considerations, and compliance standards within different industries. Essentially, understanding these metals and their respective strengths are vital in choosing the right material for any given project.

Other Articles You Might Enjoy

- Advantages of Using Beryllium Copper in CNC Machining Applications

Introduction to Beryllium Copper and CNC Machining Beryllium copper, often referred to as beryllium bronze or spring copper, is a strong, corrosion-resistant, and highly conductive metal alloy. Notably, it contains…

- Applications and Advantages of Bronze CNC Machining

1. Introduction: The Enduring Allure of Bronze in CNC Machining In this opening section, we explore the timeless appeal of bronze as a material for CNC machining. From its rich…

- The Multifaceted Applications of Bead Blasting in CNC Machining

1. Introduction: Unveiling the Versatility of Bead Blasting In this opening section, we introduce the concept of bead blasting in CNC machining and set the stage for an in-depth exploration…