- Introduction

In the context of manufacturing and industrial applications, Computer Numerical Control (CNC) processing plays a crucial role. Two such techniques integral to these operations are CNC milling and drilling.

1.1 Definition of CNC Milling and CNC Drilling

CNC milling is defined as a machining process where rotating cutting tools remove material from a workpiece in multiple axes. Its diverse capabilities include shaping complex metal parts and creating intricate designs, rendering it instrumental in tool-making and die-casting industries.

On the other hand, CNC drilling is primarily focused on generating holes within a surface using automated machinery. It is characterized by its efficiency and accuracy, making it suitable for mass production industries that require numerous identical perforations.

1.2 Brief Overview of their use in Manufacturing Industry

CNC milling and drilling play an indispensable part in today’s advanced manufacturing processes. For instance, CNC milling empowers production units to create customized components for various sectors including automotive, aerospace, defense, and electronics, among others.

Conversely, CNC drilling’s high-speed performance delivers consistency and precision, particularly in products requiring equal-distance hole placements like circuit boards or radiator cores. Industries such as consumer goods, medical device manufacturing, and telecommunications benefit extensively from this technique.2. Comprehensive Analysis of CNC Milling

This section dedicates itself to a thorough exploration and analysis of the Computer Numerical Control (CNC) milling process, including its intricacies, variations, pros and cons.

2.1 Understanding the Process of CNC Milling

At its core, CNC milling is a machining method that employs computer-operated machines to perform high-precision cuts and shapes on materials such as metals and plastics. The CNC machine relies on digital instructions derived from CAD/CAM (Computer-Aided Design/Manufacturing) software, consequently providing exceptional accuracy. During operation, rotating multi-point cutting tools progressively remove material from the workpiece, eventually resulting in the desired shape or design.

2.2 Different Types of CNC Milling Machines

There are several types of CNC milling machines categorized based on their operational capabilities and structural features. These include vertical mills—mainly for flat surfaces with cut layers; horizontal mills used for making slots and grooves; turret mills suitable for tweaking moving parts; bed mills for larger tasks due to lack of moving sections; and mill-drills which serve dual purpose drilling and end milling.

2.3 Advantages of CNC Milling

The most striking advantage of CNC milling lies in its precision—an aspect vital to industries where utmost exactitude is mandatory. Apart from high accuracy levels, other benefits of this method encompass repeatability – ensuring consistent outcomes, scalability for high production volumes, versatility through the utilization of different cutters, shorter lead time, and minimal errors leading to reduced waste.

2.4 Disadvantages of CNC Milling

While immensely beneficial, certain drawbacks persist within CNC milling. High upfront costs associated with procuring and maintaining complex machinery can be discouraging, particularly to small-scale entities. Another downside includes the steep learning curve agents operating these machines often face. Furthermore, neglection towards regular maintenance can result in compromised performance over time.

2.5 Case Studies on Effective Usage of CNC Milling

To illustrate real-world use of CNC milling, several successful case studies will be presented. These instances are drawn from diverse industries where this methodology has proven instrumental in improving profitability, time efficiency, and accuracy. The goal of these stories is to highlight the manifold ways in which CNC milling can optimize operations when deployed effectively.3. Detailed Explanation of CNC Drilling

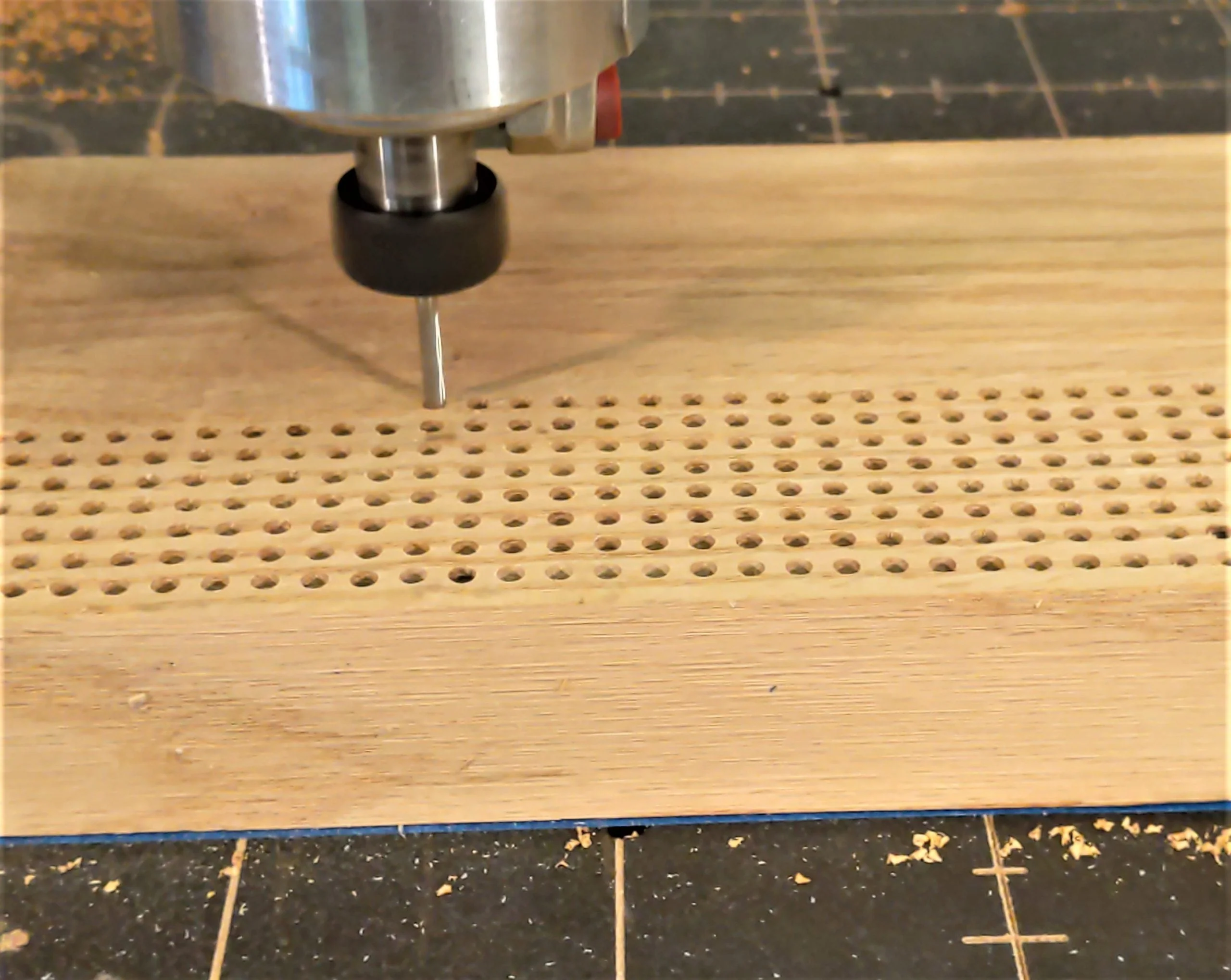

3.1 Understanding the Process of CNC Drilling

CNC Drilling is an automated process that employs computer-guided machinery to drill holes into materials. This technique uses programming software to input specifications and coordinate system instructions, which guide a series of drills in creating precise holes in various patterns at high speeds.

3.2 Variety of CNC Drilling machines

There are several types of CNC drilling machines available in the market, each designed for specific applications. These include vertical drills, horizontal drills, and radial arm drills. Vertical drills are ideal for lightweight workpieces; horizontal drills manage heavy-duty tasks efficiently, while radial arm drills allow significant maneuverability with adjustable machinery arms.

3.3 Benefits of CNC Drilling

The use of CNC Drilling comes with numerous benefits. It increases efficiency by executing complex drilling tasks quickly and precisely. It enhances consistency as the machine’s programming allows repeatable accuracy. Its automation reduces labor costs and human errors, contributes to safer working conditions, and provides flexibility due to its adaptability to different jobs.

3.4 Limitations of CNC Drilling

While beneficial, CNC Drilling does have limitations. For one, it simply can’t match the versatility provided by milling since it only executes linear vertical movements. That said, careful consideration should be taken when selecting tooling for materials prone to heat damage or distortion. Moreover, initial setup and maintenance costs could be higher due to many sophisticated parts and necessary periodic calibration.

3.5 Real-world Examples showcasing efficient use of CNC Drilling

Several industries employ CNC Drilling for their production processes. For instance, the automotive industry uses it for manufacturing precision components such as brake systems and engine parts. In aerospace, CNC Drilling is utilized for constructing fuselage sections, wings, and other critical aircraft structures due to highly demanding standards for durability and precision. Similarly, electronics manufacturers also leverage this technology to produce printed circuit boards (PCBs), where highly accurate drilling is crucial in the production process.4. Comparative Study between CNC Milling and CNC Drilling

In this section, we conduct a comparative study of both CNC milling and drilling processes based on several crucial factors.

4.1 Point by Point Comparison Based on Various Factors:

a. Material Types: Both processes work with numerous materials. However, CNC milling might not be as efficient with harder materials as CNC drilling that easily penetrates solid objects due to its focused point pressure.

b. Precision: While both methods offer high precision, CNC milling has an advanced edge due to its multi-axis capability which enables it to perform complex cuts more accurately.

c. Capabilities: CNC mills handle more versatile operations such as contouring or slotting compared to the primary role of CNC drills; making holes in materials. CNC mills are also better at creating unique designs and complicated shapes.

d. Cost Efficiency: In terms of operation, CNC milling machines might require higher expenditures because they use more tools and take bigger space than CNC drilling machines.

e. Labor Intensity: CNC Mills often need professional operators for configuration or set up, while CNC drills have simpler procedures that even less-skilled workers can operate.

f. Production Volume: For larger production volumes involving peculiar but identical parts, CNC drilling is the likely option, whereas for short-run productions of diverse components, CNC milling would be more suitable.

4.2 Situational Analysis: When to Use Which Process?

Choosing between CNC milling or drilling depends directly on the specific requirements of your project.

CNC milling is best suited when dealing with complex geometric patterns. It is the go-to solution when designing intricate cuts, slots, engravings, and other surface details since it operates through multiple axes. This makes it ideal for projects requiring intense detailing and precision.

On the contrary, CNC drilling excels in repetitive production processes where straightforward holes need to be drilled into materials. From deep hole drilling to counterboring, countersinking or even for tapping, CNC drilling is an efficient option. Whether it’s mass scale productions in the automotive industry or small-scale household items manufacturing, the use of CNC drilling proves high effectiveness.

In conclusion, recognizing the parameters pertaining to each process helps manufacturers choose correctly- between CNC milling and drilling operations as per project requisites, thereby attaining superior results with cost-effective measures.5. Industry Perspectives

5.1 Opinions from industry experts on choosing between CNC milling and CNC drilling

Several industry professionals suggest the choice between CNC milling and drilling should depend upon the specific project requirements. Precision, complexity, and volume are pivotal deciding factors.

Experts highlight that CNC milling is an optimal option for projects requiring complex shapes and high-precision cuts. Its 3D capabilities allow it to generate a wider variety of highly detailed parts compared to its counterpart.

On the other hand, for simpler designs where creating holes in material is a priority, CNC drilling becomes an ideal choice. It executes these functions faster and more accurately than with manual methods or traditional drilling machinery.

However, these pros do not discourage cross-functionality. Many manufacturing industries adopt both processes for different stages of production, offering flexibility and comprehensive machining solutions.

5.2 Impact of these processes on different industries

The automotive industry utilises CNC milling for producing intricate engine parts. The aerospace sector also heavily relies on it due to the requirement of elaborate components and absolute precision.

Conversely, the construction industry often employs CNC drilling machines for their speed and efficiency in mass-producing uniform building materials like pipes and beams.

In electronic sectors, both techniques see usage; milling for manufacturing precisely printed circuit boards (PCBs), while drilling creates exact-sized holes within them.

Simultaneously, the medical sector benefits from both processes. Milling aids in fabricating customised prosthetic parts, whereas drilling assists in developing precise equipment like bone screws.

Thus, optimized industrial productivity can derive benefit from either technique based upon specific needs and goals.6. Future Trends

The subsection deals with the ongoing patterns and expected future advancements in CNC Milling and Drilling processes.

6.1 Current trends impacting the choice between CNC milling and CNC drilling

Automated technology is the focal point of current trends that influence the decision-making process between CNC milling and drilling. The emergence of multi-axis machines has eased operations in CNC milling, enhancing efficiency and precision execution for complex cuts. Concurrently, drilling benefits from automation by integrating robotics to handle repetitive actions leading to increased accuracy and elimination of human error.

Additionally, sustainability influences modern manufacturing techniques. There’s a steady drive towards energy-efficient machines that minimize harm to the environment. High-speed machining or HSM is also becoming mainstream due to its ability to produce parts faster, reducing production costs for both milling and drilling procedures.

6.2 Anticipated future developments in both processes

Forecasts indicate an upsurge in integrated applications within the overall CNC industry. Integrated systems such as CAD/CAM software align both processes more tightly, contributing to fewer errors, reduced waste, improved productivity and shorter lead times while maintaining superior quality standards. As advanced materials continue to emerge within the manufacturing spectrum, there will likely be enhanced machine tools to cater to these needs in both milling and drilling.

Another significant development is the growing incorporation of AI (Artificial Intelligence) and Machine Learning algorithms. These technological innovations are expected to optimize efficiencies, enhance predictive maintenance, increase tool life and reduce downtime, thus transforming both CNC milling and drilling processes moving forward.

Lastly, anticipated regulatory changes emphasizing worker safety may catalyze further automation adoption, facilitating less manual intervention and risking lesser workplace hazards in both CNC milling and drilling operations.7. Key Takeaways

7.1 Summarized Insights from the Article

The differences between CNC milling and drilling operations largely stem from their distinct machining approaches, capabilities, and applications. Milling is an inherently versatile process, best-suited for detailed and intricate jobs involving creating slots, cutting complex shapes, or producing high precision parts. It accommodates a varied range of materials from metals to plastics.

On the other hand, drilling specialises in generating holes and is more fitting for specific tasks requiring depth accuracy, quick hole creation, and repeatability. It is proficient with hard materials like steel and works efficiently on large volume production runs.

These comparisons not only highlight the fundamental distinctions but also encourage selecting between milling and drilling based on project requirements rather than general attractiveness.

7.2 Conclusion and Expert Recommendations

Both CNC milling and drilling hold significant importance in modern manufacturing industries,yet one is not inherently superior to the other; this depends entirely on the specific need. For complex geometries and precise detailing, consider the wide-ranging versatility of CNC milling. Alternatively, for a straight-forward approach primarily involved in making accurate, consistent holes, CNC drilling emerges as a competent choice.

Thus, evaluate your needs carefully before deciding on one over the other. The correct understanding of these technologies can maximize productivity, reduce costs, and improve quality in the long run. Therefore, specifying each operation’s relevance concerning the expected deliverables will contribute significantly towards effective decision-making in the selection process.

Expert recommendations are inclined towards a comprehensive analysis defined by the nature of the task at hand – whether speed, precision, complexity, or material hardness is paramount – conditions that directly impact the choice between CNC milling and drilling.

Other Articles You Might Enjoy

- The Role of Precision in CNC Machining: How Tight Tolerances Impact Cost and Quality?

Introduction: Understanding Precision in CNC Machining In manufacturing contexts, precision is epitomized by Computer Numerical Control (CNC) machining. In essence, CNC machining is a process utilized widely within the manufacturing…

- Using the Right Milling Technique: Down Milling vs. Back Milling

In the world of CNC milling, experts employ a myriad of techniques to maximize the capabilities of their CNC machines. These techniques are tailored to the size, shape, features, and…

- Hard Milling vs. Soft Milling in CNC: Material Considerations and Strategies

Introduction to Milling in CNC Manufacturing Milling, a fundamental process in Computer Numerical Control (CNC) manufacturing, plays an integral role in the production of diverse components across various industries. This…