Advanced CNC Turning Services from WANT.NET

With our online custom machining service, you can order custom parts or prototypes with just a few clicks. Turning: As an essential machining technique for parts, we offer powerful CNC Turning machine and excellent engineers to provide you with reliable and advanced technical support! All products are ISO 9001:2015, ISO 13485, and AS9100D certified or registered under ITAR.

- Free Quote and DfM

- Fast Lead Time

- Pay After Delivery

Home » CNC Machining » CNC Turning

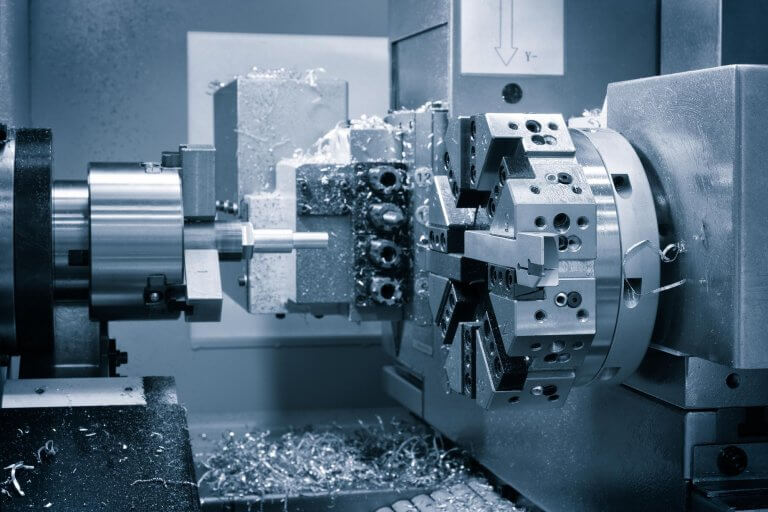

High Precision CNC Turning Service

With our own factory and our robust CNC turning manufacturer networks, we provide high precision turning service for our global clients at the most competitive price possible.

Our precision CNC lathes provide low-cost parts for simple and complex cylindrical geometries. We also use Live tooling to create precise, complex geometries for features like axial and radial holes, grooves, slots, and flats.

Full automation of these versatile machines allows us to produce hundreds of similar dimensions easier, faster, and cost-effectively.

Item | Specification / Capacity | Remarks |

Minimum Turning Diameter | Ø3 mm | Common for high-precision machining of small parts, typically used in small electronic components or precision instruments. |

Maximum Turning Diameter | Ø300 mm | Suitable for general industrial parts, such as mechanical components, automotive parts, etc. |

Maximum Turning Length | 500 mm | Suitable for medium-sized parts, fulfilling the needs of industries like valve bodies, brackets, etc. |

Dimensional Tolerance (Diametrical Tolerance) | ±0.01 mm | Suitable for most industrial parts, especially for high-precision mechanical components such as brackets and shafts. |

Concentricity | ±0.02 mm | Meets higher precision requirements, ensuring mechanical assembly alignment. |

Surface Roughness (Ra) | 0.8 – 3.2 µm | Achievable through appropriate tool selection and feed rate, suitable for most parts with standard surface finish requirements. |

Weekly Production Capacity | Approx. 2,000 pcs/week | Based on order volume and part complexity, average delivery is 2,000 parts per week, offering flexibility in production. |

Finished Goods Acceptance Rate | 98% | Maintained through rigorous quality control processes, ensuring product precision and consistency, meeting customer expectations. |

CNC Turning Precision & Consistency

- Our precision management in CNC Turning Service adopts a dual approach: on-machine probes provide immediate feedback for tool compensation, while post-production checks use CMMs and laser scanners for spot verification.

- We’ve built a dedicated process database for various materials and common part types, listing key cutting parameters like spindle speed, feed rate, and tooling options—this streamlines our CNC Turning Service and minimizes manual errors.

- For products with extremely tight tolerances, we schedule periodic in-process inspections (e.g., every 20–30 pieces) and upload measurements to our MES system. Any anomaly triggers a halt for immediate investigation, preventing large-scale defects.

- Owing to rigorous procedures and data-driven oversight, our CNC Turning Service maintains a consistent acceptance rate of over 98%, even when dealing with intricate geometries or micro-feature parts.

- This high level of precision and uniformity not only highlights our CNC Turning Service expertise but also underpins the reliability of customers’ finished products.

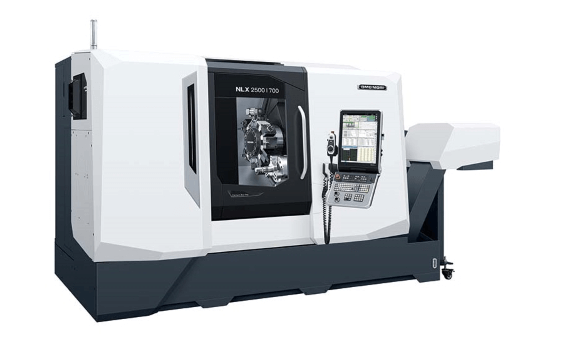

Advanced Equipment & Technology

- We have invested in multiple high-precision CNC Turning machines, including the Mazak Integrex i-200 and DMG MORI NLX2500, each capable of spindle speeds up to 4500 rpm and a repeat positioning accuracy of around ±0.005mm.

- These lathes support multi-axis operations, allowing turning, drilling, and milling to be done in a single setup, minimizing both setup errors and tool-change times.

- In our CNC Turning production line, we also incorporate automatic loading systems and real-time monitoring sensors that track cutting forces, tool wear, and other vital data. Any deviation triggers an alert, prompting immediate parameter adjustments.

- Additionally, we adopt toolpath optimization strategies for each material batch, pairing high-efficiency cutting tools with purpose-specific coolants. This ensures that even at high feed rates, we maintain excellent surface integrity throughout the CNC Turning process.

- We routinely calibrate these machines and log their performance metrics monthly, ensuring our CNC Turning equipment stays in top shape and consistently delivers high-quality results.

Wide Range of Materials

- Our CNC Turning capabilities span common metals such as aluminum alloys (e.g., 6061, 7075), stainless steels (304, 316L), carbon steels, and titanium alloys. We can also handle copper, brass, and other non-ferrous metals.

- Each material exhibits unique cutting behaviors—hardness, heat dissipation, or stickiness—so we adjust tool geometry and cutting parameters accordingly.

- For instance, we employ high-rake tooling and higher cutting speeds for aluminum alloys, while tougher materials like stainless steel or titanium demand wear-resistant carbide tools with lower feed rates.

- We also use coolant spray or mist lubrication systems in specific CNC Turning applications where heat buildup can degrade surface quality.

- By fully understanding these material properties, we deliver reliable CNC Turning parts to various industries, balancing mechanical performance with impeccable surface finishes.

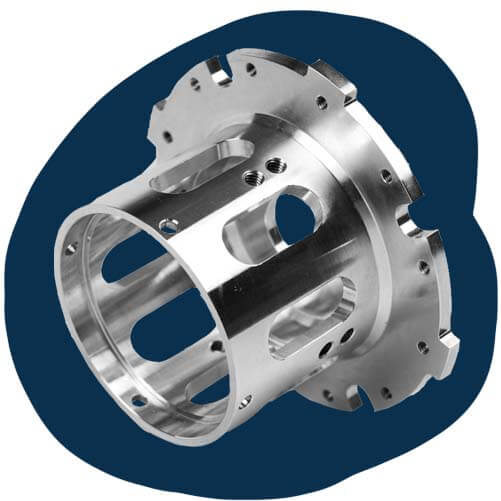

CNC Turning Complex Part

- When dealing with intricate geometries or parts containing internal cavities, our CNC Turning and turn-mill processes reduce multiple setups into a single operation, mitigating alignment errors.

- Before mass production, our team runs CAM simulations of CNC Turning toolpaths, identifying potential collisions or interference points and making preemptive adjustments.

- If the part requires unique clamping solutions—due to irregular shapes or minimal clamping surfaces—we develop custom fixtures and specialized cutting tools for added stability.

- For detailed features such as steps, contours, or thin walls, we employ finishing passes at lower feed rates and cutting depths to achieve precision and minimize cutting forces.

- By combining these methods, we have delivered complex CNC Turning projects for aerospace brackets, medical device components, and high-precision optical assemblies.

Strict Quality Control

- Our QA covers every stage of the CNC Turning workflow, from incoming materials verification to final inspection, with standardized procedures and thorough documentation.

- In-process monitoring features integrated probing systems that compare real-time measurements against setpoints, supplemented by vision inspection to detect surface defects.

- Once CNC Turning is finished, our inspectors run dimensional and surface tests with CMMs on randomly sampled parts. Should any irregularities arise, we immediately isolate that batch and initiate root-cause analysis.

- Each part is traced via a unique code, linking it to machine ID, tooling data, and processing time, aiding future reference or defect analysis.

- We periodically review and refine these quality protocols to keep pace with new CNC Turning methods, consistently delivering a high-quality product.

Why Choose Our Online Custom CNC Machining Service

Advanced turning capabilities are one of the key technologies that make customers choose us for custom part machining.Choose us for your CNC turning needs and get a quick and accurate CNC turning quote for your turning parts online.

What is CNC Turning: Definition, Process & Applications

What is CNC Turning Technology? CNC (Computer Numerical Control) turning is a machining process where a cutting tool, typically a non-rotary tool bit, removes material

Get a Quick Quote Now

You’re 1-step away from our incredible quote of CNC turning service.

- All uploads are secure and confidential