Plastic and rubber parts are a common sight in the industry. Most of these parts are made through molding techniques, with injection and transfer molding being key examples. But which technique is better in Injection molding vs Transfer molding? That’s the question most manufacturers and product developers raise.

This article aims to provide that answer by thoroughly comparing these two molding methods. It will detail their strengths and weaknesses and discuss suitable applications for each technique.

What is Transfer Molding?

Transfer molding is a plastic molding technique where a preformed thermosetting polymer is placed in a pot, heated, and pressurized to flow into a closed cavity. It cures and attains the desired shape.

Transfer Molding Process

There are two variants. In one case, the preformed plastic is in a “pot” and flows into the mold cavity via vertical runners. Silicone rubber molding is an example. In the second case, a plunger forces the heated material through side channels into the mold. Resin transfer molding is an example of this variant.

The transfer molding technique is best for thermosetting materials but can also work for some thermoplastics. Compatible materials include silicone rubber, unsaturated polyester, epoxy, and PF plastic.

Advantages and Disadvantages of Transfer Molding

Transfer molding is a simpler process and offers multiple advantages over other methods.

Advantages:

- Low Setup and Maintenance: The setup is simple and easy to maintain as there is no complex machinery.

- Best for Metal Inserts: Molding is better suited for adding metal inserts to molded products.

- Sharper and Thicker Edges: Higher pressures enable sharper, more defined edges.

- Part Design Flexibility: Accommodates complex shapes and intricate designs with ease.

Disadvantages:

- Slower Production Speed: The transfer process molding is slower compared to its counterpart, primarily due to the time needed to preheat materials before they enter the mold.

- More Material Waste: Material gets wasted during mold transfer as some of it solidifies in sprue and overflow grooves.

- Small Volume Production: Transfer molding machines are usually designed for fewer cavities, meaning they produce less output per cycle. They are best for low to medium production.

What is Injection Molding?

Injection molding is an advanced form of transfer molding in which a thermoplastic in granular form is fed into the machine. It is heated to change into a highly plastic form and then injected via screw-ram directly into the mold. The whole process is quicker and takes 30 seconds to a minute to create a part.

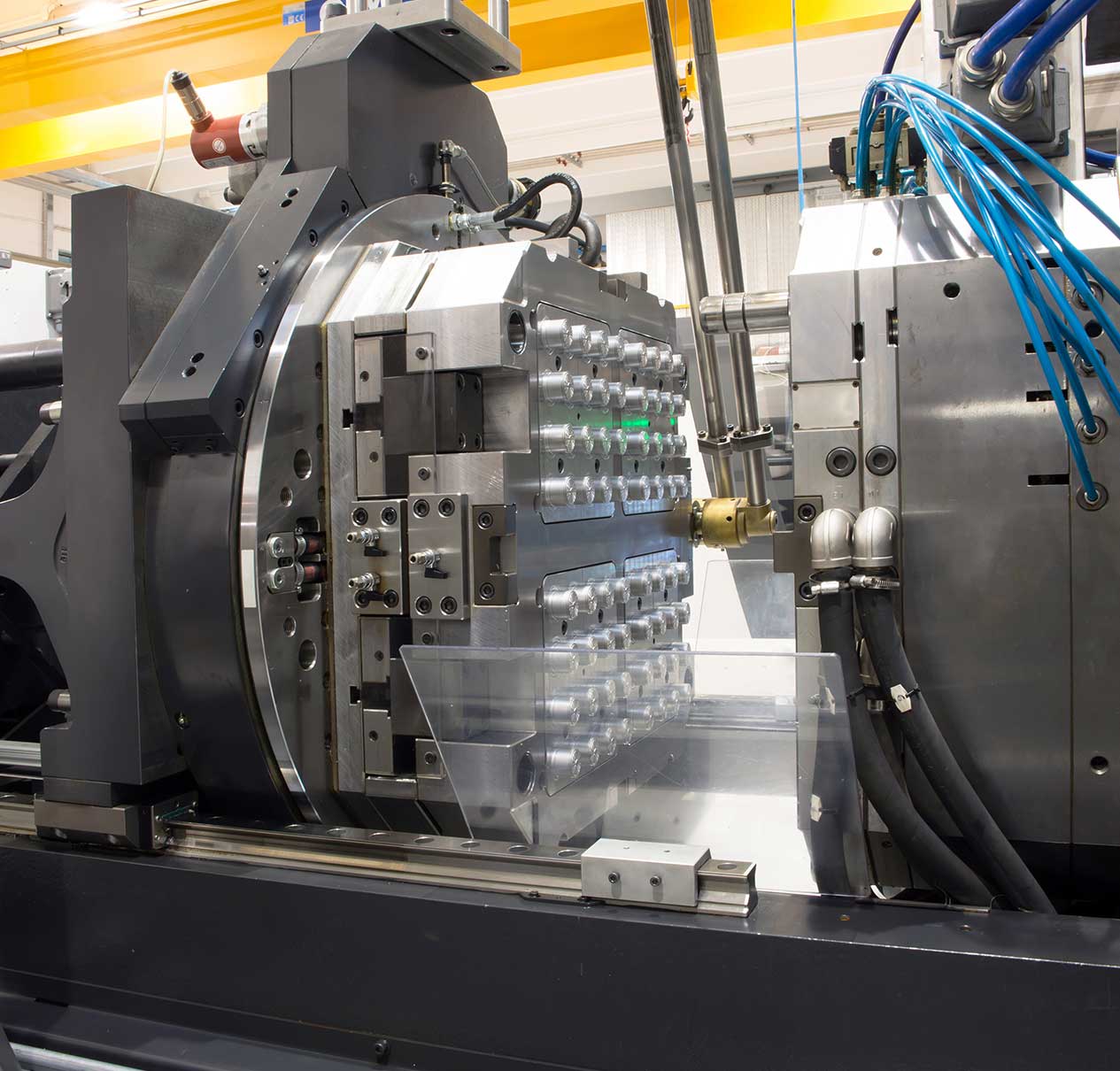

A Typical Injection Molding Setup

Plastic injection molding is ideal for making complex and intricate shapes. But with more cavities and complex designs, it becomes slightly expensive to make the mold. However, in the long term, or bulk production of quantities of larger thin-walled parts, the process becomes economical.

The part weight in injection molding can be as light as 50 g (simple casings) and as high as 25 kg when making large parts such as refrigerator doors and car bumpers.

The injection molding process primarily involves thermoplastics. However, one can also mold thermosets and elastomers but you’ll have to make some modifications to the equipment. The common materials best suited for the process are liquid rubber, polyethylene, polyamide, PVC, ABS, and PP.

Advantages and Disadvantages of Injection Molding

As a relatively modern version of the rubber transfer molding process, it performs better in certain areas. Here are some strengths of the process:

Advantages:

- Quicker Process: The process is relatively quick, with production cycles between 30 seconds to a minute. For larger parts, the cycle might extend slightly.

- Complex and Intricate Parts: This method allows for the creation of complex and intricate shapes. It can handle parts ranging from 50 grams to 25 kilograms.

- Thin-Walled Casings: Particularly effective for manufacturing thin-walled casings for equipment. Ensures precision in molding thinner structures.

- Economical for High Volumes: The molds are expensive to make, which makes the process more economical for high-volume production.

Disadvantages:

- High Setup Costs: Injection molding equipment is relatively more expensive than transfer molding machines. Their setup process is also more complex.

- Rounded Corners: Injection molds produce parts with rounded corners. They are less capable of creating sharp corners compared to other methods.

- Thin Walls Requirement: The process necessitates uniform thin walls between 0.4 mm and 12.5 mm in thickness. Parts that are too thick or molds that are non-uniform can lead to defects in the molding process.

Thermosetting Materials vs. Thermoplastic Materials

Thermosetting Materials

Suitable for: Thermosetting materials are typically used for products requiring high heat resistance, chemical resistance, and structural stability. These materials become very hard and irreversible once cured.

Reasons for Choosing:

- High Heat Resistance: Thermosetting materials remain stable at high temperatures and do not deform or melt.

- Chemical Resistance: Highly resistant to most chemicals, suitable for chemical industries and medical devices.

- Structural Stability: High strength and rigidity once cured, suitable for high-stress environments.

Common Applications: Electrical insulation materials, automotive parts, electronic device housings, high-strength composites.

Thermoplastic Materials

Suitable for: Thermoplastic materials are ideal for products requiring flexibility, reprocessability, and recyclability. These materials soften when heated and can be reshaped multiple times.

Advantages:

- Reprocessability: Can be reshaped by heating, making them highly recyclable.

- Flexibility: Can create complex and intricate structures, suitable for a wide range of applications.

- Less Material Waste: Lower material waste during production, and waste can be recycled.

Disadvantages:

- Lower Heat Resistance: May deform or melt at high temperatures, not suitable for high-temperature environments.

- Lower Chemical Resistance: Less resistant to certain chemicals, limiting their use in some fields.

Common Applications: Packaging materials, everyday items, medical devices, automotive interiors, electronic product housings.

Material Waste and Recycling

Material Waste

Injection Molding: The material primarily stays within the cavity, resulting in less waste. The waste material can be reprocessed by reheating and reusing it.

Transfer Molding: The material solidifies in the sprue and overflow grooves, resulting in more waste. Thermosetting materials, in particular, cannot be reused once they solidify.

Recycling Processing

Injection Molding Waste Processing:

- Reprocessing and Reuse: Waste can be reheated and reused in production, reducing material waste.

- Circular Economy: Waste is converted into new raw materials through recycling systems, supporting sustainable production.

Transfer Molding Waste Processing:

- Limited Recycling: Thermosetting material waste is difficult to recycle and often requires incineration or landfilling.

- Optimized Design: Reducing material waste through optimized mold design and process flow.

Energy Consumption

Injection Molding: Due to shorter production cycles, energy consumption is high, especially in mass production. Optimizing the production process can reduce energy consumption, such as using efficient heating systems and automated equipment.

Transfer Molding: Preheating the material and longer production cycles increase energy consumption. Improving preheating equipment and process flow can reduce energy consumption.

Optimizing Production Processes to Reduce Energy Consumption

- Using Efficient Heating Systems: Adopting energy-efficient heaters and temperature control systems to improve energy efficiency.

- Automation and Smart Manufacturing: Introducing automated equipment and smart manufacturing technologies to enhance production efficiency and reduce energy waste.

- Process Optimization: Reducing unnecessary energy consumption through process flow optimization and equipment maintenance.

Key Differences Between Injection Molding and Transfer Molding

Comparison of Working Processes

The principle behind the processes is similar, both involving heating and pressurizing the polymer into the mold. However, there’s a slight difference in their working process.

In injection molding, the polymer is fed in the form of pellets into the machine, transforming into a molten state and then getting injected under pressure. Typically, the assembly and injection are horizontally aligned.

Whereas, in transfer molding, a pre-heated preform material is pushed by a plunger into the mold. The force or push is in this case in the vertical direction.

Production Speed and Efficiency

In injection molding, the material moves directly into the mold cavity. And in most cases, it hardly takes a couple of seconds to a minute to make one mold product.

However, in transfer molding, the charge moves from the pot into the sprue and then cures inside the mold, significantly adding more time. Also, in this case, we preheat the material before placing it in the pot, which further adds more time to the production cycle.

Precision and Tolerances

The precision in both processes is dependent on the mold. If the mold is CNC machined, you can expect precision between 0.05 to 0.01mm in each case. However, injection molding doesn’t make sharp edges. In most cases, you end up getting rounded edges.

Waste and Flash

Since both are plastic molding techniques, when the material solidifies in between channels, waste is common. But the amount varies.

In injection molding, the polymer largely stays within the cavity, so you see very little flash (extended portion of the material). Whereas, in transfer molding, the amount of waste is significantly higher. This is because of large sprue channels, air holes, and overflow grooves. It is particularly more when working with thermosetting material, which we cannot reuse after they solidify.

Materials Used

Transfer molding is more suitable for thermoset materials, although they

can work with some thermoplastic materials. Examples include silicone rubber, unsaturated polyester, epoxy, and PF plastic.

Likewise, injection molding is more suitable for thermoplastics but can also mold a few thermosets. Liquid silicone rubber, polyethylene, polyamide, PVC, ABS, and PP are common materials.

Equipment Differences

Both processes utilize different equipment. The transfer molding machine is vertically designed with a charge pot and plunger mechanism on the top and a mold cavity beneath it – a vertical configuration. The pre-heating equipment is separate.

In the case of injection molding, the machine itself contains two compartments, one for heating the thermoplastic pellets and one for the clamping mold cavity. The machine expands lengthwise, where the material is fed from one end and pushed horizontally through a screw into a mold on the other end. However, this setup can vary based on applications.

Applications

The two plastic processes seem similar but considering their materials compatibility and machine configurations, the applications and use cases are quite different.

Transfer molding is suitable for small to medium-scale production of small rubber parts. Its common applications are seals, pins, connectors, and studs. Whereas, injection molding is for high-volume production of small to large parts, particularly thin-walled substrates.

Its applications spread across a range of industries, including automotive, medical, food, electronics, and construction. Car bumpers, refrigerator doors, packaging, electronic equipment casing, and overcaps – all are injection molded products.

Cost Comparison

Typically, the manufacturing processes have three types of costs: setup costs, operational costs (materials, power, and labor), and maintenance costs.

In terms of investment, an injection molding machine is quite costly, with prices ranging between $50,000 to $100,000. Transfer molding machines are relatively cheaper, available for $10,000 to $50,000.

Materials costs are relatively similar, but more material gets wasted in transfer molding, affecting costs slightly. In some cases, the material properties demand different machinery. For instance, materials requiring a high injection pressure also demand more powerful molding machinery, which is costly.

The larger share of operational costs goes to mold design. In both cases, if the mold design is complex, both processes will incur high costs. Transfer molding may be easy to set up with low investment costs, but for large-scale productions, injection molding is more cost-effective.

Comparison Summary

| Injection Molding | Transfer Molding | |

|---|---|---|

| Production Volume | Medium to Large | Small to medium |

| Speed | Quicker | A bit slower |

| Equipment | Heating Equip+ Hydraulic Screw+ Mold | Plunger + Mold |

| Waste | Less Waste | More Waste |

| Tolerance | 0.05 – 0.01mm | 0.05 – 0.01mm |

| Materials | PP, PA, PVC, Liquid Silicone Rubber, ABS | Epoxy, PF Plastic |

| Applications | Studs, connectors, rubber seals | Bumpers, equipment casing, over caps |

| Machine Costs | $50,000-$100,000 | $10,000-$50,000 |

How to Choose Between Injection Molding and Transfer Molding?

Transfer molding and injection molding both have their use cases and strengths. Overall, injection molding is an advanced technique with a large number of applications. However, choose based on your needs and requirements.

Choose injection molding if you want to bulk-produce thin-walled castings or complex structure thermoplastic components. Select transfer molding if you want to design rubber seals.

Looking for expert injection molding services? Look no further than RapidDirect Custom Injection Molding Services. We specialize in crafting plastic parts to meet specific size, complexity, and volume needs. Choose from over 30 thermoset and thermoplastic materials for your project.

Our facility has machines from 30t to 1800t, perfect for both prototypes and full-scale production. Benefit from our complimentary design consultation with every order. We promise quick delivery, with lead times starting at just 15 days.

Try RapidDirect Now!

Get Quote

Comparing Differences Between Injection Molding and Compression Molding

Compression molding stands as a time-tested, straightforward method for shaping thermoset materials. In this process, a pre-heated mass, or ‘charge,’ is placed into the lower section of a heated mold. The closing of the upper mold exerts pressure, sculpting the charge into the desired form. The heat within the mold not only shapes but also triggers polymerization, essential for curing the material.

On the other hand, injection molding takes a different approach. It begins with feeding thermoplastic pellets into a hopper. These pellets are then melted and injected under high pressure into a secured mold, where they take on the mold’s shape.

Compression Molding Working Process

Firstly, both processes differ in the working process. Then, in material placement. In compression molding, the material is fed into the mold directly whereas in injection molding the material is fed to the feed hopper. The machine orientation also differs. In compression molding technique, it’s vertical while in injection molding it is usually horizontal.

The best materials for compression molding are melamine, urea-formaldehyde, epoxies, urethane, and elastomers. Whereas, injection molding works best with polyamide, polypropylene, ABS, PVC, and liquid silicone.

Other Articles You Might Enjoy

- Finishing Options for Injection-Molding

Factors that impact the injection molding surface finish The best way to control the texture of plastic parts is to treat them with a specific finishing process. There are steps…

- Best Wall Thickness for Injection Molding

Injection molding has been the dominant method of consumer manufacturing since the 1950s. It is responsible for everything, from action figures to denture boxes. Injection molding is versatile, but there…

- The Basics of Injection Molding: Procedure, Pros, and Applications

Introduction to Injection Molding Injection molding is a predominant manufacturing process used to create plastic parts by injecting molten material into a specific mold shape. This technique allows for the…

- Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is a high-precision manufacturing process used in producing miniature and intricate plastic parts. This procedure, employing specialised machines with high-pressure moulding capabilities…

- Everything You Should Know About ABS Injection Molding

ABS is a common plastic injection molding material that contains three main ingredients. ABS's "A", acrylonitrile, confers hardness, heat, and chemical resistance. The "B", which is butadiene, gives toughness and resistance…

- Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is an advanced manufacturing technique that miniaturizes traditional injection molding processes. The principle of micro injection molding revolves around producing tiny, intricate…