High-strength and ultra-high-strength steels (HSS and UHSS) are engineering marvels, known for their exceptional combination of strength and toughness. These steels are crucial in industries such as aerospace, automotive, and heavy machinery, where durability and reliability are paramount. However, their impressive properties also make them some of the most challenging materials to machine. For buyers sourcing CNC machined parts made from HSS and UHSS, understanding the intricacies of machining these materials is essential to selecting the right supplier.

This comprehensive guide delves into the unique characteristics of high-strength and ultra-high-strength steels, the challenges they present in CNC machining, and the advanced techniques required to machine them effectively. By the end of this article, buyers will be better equipped to evaluate suppliers and ensure their high-strength steel components meet the highest standards of precision and quality.

Understanding High-Strength and Ultra-High-Strength Steel

High-strength and ultra-high-strength steels are defined by their superior strength and toughness. Generally, steel is classified as high-strength when its tensile strength exceeds 1200 MPa and as ultra-high-strength when it surpasses 1500 MPa. These steels are typically low-alloy or medium-alloy steels that have been heat-treated to achieve their remarkable properties.

Types of High-Strength and Ultra-High-Strength Steel

- Low-Alloy HSS/UHSS: These steels contain up to 6% alloying elements, such as chromium, nickel, and manganese. Examples include chromium-nickel steels and chromium-molybdenum steels.

- Medium-Alloy HSS/UHSS: These steels have higher alloy content and may include elements like molybdenum, vanadium, and tungsten. Examples include chromium-nickel-tungsten steel and chromium-nickel-molybdenum steel.

- High-Alloy HSS/UHSS: These steels are heavily alloyed with a variety of elements to enhance their mechanical properties. Examples include chromium-manganese-titanium steel and chromium-nickel-molybdenum-vanadium steel.

After heat treatment, such as quenching and tempering, these steels exhibit a tensile strength ranging from 1200 to 1960 MPa and a hardness of 35 to 50 HRC. The relationship between tensile strength and hardness is crucial; while increased hardness often corresponds to increased strength, HSS and UHSS are defined by their overall mechanical properties, including toughness and ductility.

Challenges in Machining High-Strength and Ultra-High-Strength Steel

The very properties that make HSS and UHSS valuable also contribute to the significant challenges encountered during machining. Here are the primary difficulties:

- High Cutting Forces: The high shear strength of HSS and UHSS results in significant resistance to deformation, leading to cutting forces that are 1.25 to 1.8 times greater than those required for machining standard steels like 45 steel.

- Elevated Cutting Temperatures: These steels have lower thermal conductivity, approximately 60% of that of 45 steel, which causes heat generated during cutting to concentrate in the cutting zone. This can raise cutting temperatures by 60% compared to machining standard steels.

- Rapid Tool Wear: Due to the high cutting forces and temperatures, as well as the presence of hard carbides and other alloying elements, tools experience accelerated wear through abrasion, diffusion, and oxidation. This leads to shorter tool life and more frequent tool changes.

- Difficulty in Chip Breaking: The high toughness and strength of these steels make chip breaking difficult. Long, continuous chips can wrap around the tool or workpiece, disrupting the machining process and potentially causing damage.

Best Practices for Machining High-Strength and Ultra-High-Strength Steel

To successfully machine HSS and UHSS, it is essential to optimize tool selection, cutting parameters, and machining strategies. Below are some best practices to consider:

1. Selecting the Right Tool Materials

The choice of tool material is critical when machining HSS and UHSS. The tools must withstand high cutting forces, resist wear, and maintain their cutting edges at elevated temperatures.

- High-Performance High-Speed Steel (HSS): These include high-cobalt, high-vanadium, and powder metallurgy HSS. They offer better wear resistance and higher hot hardness compared to traditional HSS. Examples include M42 and M4 HSS.

- Cemented Carbide: Carbide tools are preferred for their superior hardness and wear resistance. Coated carbides, such as those with TiAlN or TiCN coatings, provide additional resistance to heat and wear, making them ideal for machining HSS and UHSS.

- Ceramic Tools: Ceramic tools are highly effective for turning and milling operations on HSS and UHSS due to their excellent wear resistance and ability to maintain hardness at high temperatures.

- PCBN (Polycrystalline Cubic Boron Nitride): PCBN tools are among the hardest materials available for cutting tools, making them suitable for high-speed finishing operations on HSS and UHSS.

2. Optimizing Tool Geometry

Tool geometry significantly impacts tool performance and the overall success of machining operations on HSS and UHSS. Proper tool geometry can reduce cutting forces, minimize heat generation, and improve chip control.

- Rake Angle: A reduced rake angle (0° to 4°) enhances tool strength and minimizes the risk of tool breakage. For ceramic tools, negative rake angles (-10° to -4°) may be used to further increase tool strength.

- Relief Angle: A smaller relief angle (5° to 10°) reduces the contact area between the tool and the workpiece, helping to manage heat and reduce tool wear.

- Cutting Edge Radius: A larger cutting edge radius (0.8 to 1.6 mm) helps distribute cutting forces more evenly, reducing the likelihood of tool chipping and improving surface finish.

- Helix Angle (for end mills): A lower helix angle (30° to 35°) is preferred to reduce the radial forces that contribute to tool deflection and wear.

3. Setting Cutting Parameters

Cutting parameters must be carefully selected to balance tool life, machining efficiency, and workpiece quality. Here are the key considerations:

- Cutting Speed: Lower cutting speeds are generally recommended for HSS and UHSS to reduce heat generation. For high-speed steel tools, cutting speeds should be between 3 to 10 m/min, while for carbide tools, speeds can range from 30 to 70 m/min. Ceramic tools can handle speeds of 40 to 120 m/min, and PCBN tools can reach up to 200 m/min.

- Feed Rate: Feed rates should be sufficient to cut through the work-hardened layer from the previous pass. Typical feed rates range from 0.1 to 0.4 mm/rev.

- Depth of Cut: The depth of cut should be deep enough to penetrate beneath any work-hardened layer. For roughing operations, depths of 1 to 5 mm are common, while finishing cuts may use depths of 0.2 to 0.5 mm.

4. Chip Control Techniques

Controlling chip formation is crucial in machining HSS and UHSS. Proper chip control prevents tool damage and ensures smooth machining operations.

- Chip Breakers: Use inserts with built-in chip breakers designed for tough materials to ensure that chips break into smaller, manageable pieces.

- Obstruction-Based Chip Breaking: Employ adjustable chip-breaking plates or elastic chip breakers to force chips to break, especially in continuous cutting operations.

- Tool Geometry Adjustments: Increase the main cutting edge angle and reduce the rake angle to enhance chip deformation and breakage.

- Optimizing Cutting Conditions: If chips are not breaking properly, increasing the feed rate or reducing the cutting speed can often help.

- Pre-Grooving the Workpiece: For extremely tough materials, consider pre-machining grooves into the workpiece surface to encourage chip breakage during the main cutting operation.

5. Advanced Machining Techniques

In addition to standard machining practices, advanced techniques can help overcome the challenges of machining HSS and UHSS.

- Interrupted Cutting: Implement interrupted cutting methods, such as milling, to reduce continuous tool contact and lower heat buildup.

- Cryogenic Cooling: Using liquid nitrogen or other cryogenic coolants can help manage the high temperatures associated with machining HSS and UHSS, prolonging tool life and improving surface finish.

- Vibration-Assisted Machining: Introducing controlled vibration into the machining process can help break chips more effectively and reduce cutting forces.

Data Tables: Cutting Parameters and Tool Selection for HSS/UHSS Machining

Table 1: Recommended Cutting Parameters for HSS/UHSS Machining

| Tool Material | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Application Notes |

|---|---|---|---|---|

| High-Speed Steel (HSS) | 3 – 10 | 0.1 – 0.3 | 0.3 – 3 (Roughing) | Suitable for low-speed machining |

| Cemented Carbide | 30 – 70 | 0.15 – 0.4 | 1 – 5 (Roughing) | Use coated tools for longer life |

| Ceramic | 40 – 120 | 0.05 – 0.5 | 1 – 4 (Finishing) | Best for high-speed operations |

| PCBN | 100 – 200 | 0.1 – 0.3. | 0.5 – 3 | Ideal for high-speed finishing |

Table 2: Tool Material Selection for HSS/UHSS Machining

| Tool Material | Characteristics | Recommended Operations |

|---|---|---|

| High-Speed Steel (HSS) | Good toughness, moderate wear resistance | Drilling, tapping, low-speed milling |

| Cemented Carbide | High hardness, excellent wear resistance | General turning, milling, roughing |

| Ceramic | Excellent high-temperature hardness | High-speed turning, milling, finishing |

| PCBN | Extreme hardness, high thermal stability | Precision finishing, hard turning |

Practical Tips for Machining High-Strength and Ultra-High-Strength Steel

To maximize efficiency and precision when machining HSS and UHSS, consider the following practical tips:

- Use Climb Milling: For milling operations, climb milling helps reduce work hardening and tool wear by ensuring that the cutting edge engages the workpiece material favorably.

- Monitor Tool Wear: Regularly inspect tools for signs of wear, particularly when machining UHSS. Early tool replacement can prevent machining defects and reduce downtime.

- Optimize Tool Paths: Plan tool paths to minimize the tool’s exposure to work-hardened material, which helps extend tool life and improve surface finish.

- Custom Tooling: Consider custom-designed tools if standard options are not providing the desired performance. Custom tools can be optimized for specific operations, such as deep hole drilling or complex geometries.

- Advanced Coolants: Use advanced coolants or lubrication systems that can manage the extreme heat generated during machining, such as high-pressure cooling systems or cryogenic coolants.

Mastering the machining of high-strength and ultra-high-strength steels requires expertise, the right equipment, and optimized processes. As a buyer, selecting a CNC machining supplier who possesses these capabilities is critical to ensuring the quality and performance of your HSS and UHSS components. Look for suppliers who:

- Have extensive experience in machining HSS and UHSS materials.

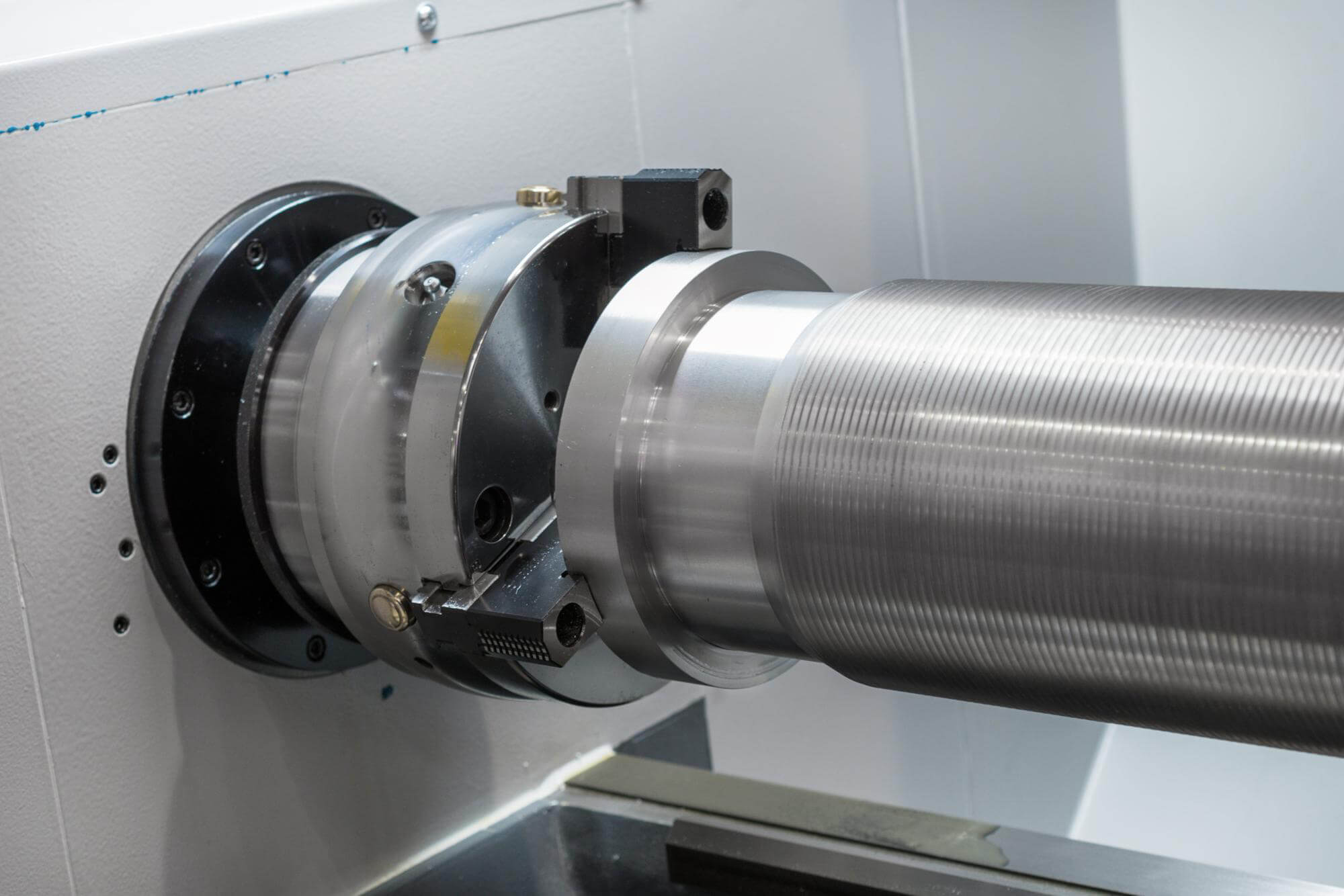

- Utilize advanced CNC machinery with high precision and high rigidity.

- Implement rigorous tool management systems to ensure consistent quality.

- Provide detailed process documentation, including cutting parameters and tool usage data.

By choosing a supplier with these capabilities, you can ensure that your CNC machined parts, particularly those made from high-strength and ultra-high-strength steel, meet the highest standards of quality and performance.

Other Articles You Might Enjoy

- The Efficiency of CNC Machining: Titanium vs. Steel for High-Performance Components

Introduction to CNC Machining and Material Selection Computer Numerical Control (CNC) machining revolutionizes the manufacturing space by enabling highly accurate, repeatable, and complex component production. In high-performance industries like aerospace…

- Understanding Bead Blasting in CNC Machining(compressive strength Otto)

Bead blasting is a process appended to Computer Numerical Control (CNC) machining used prominently for surface finishing. It gives the products a clean and appealing look by eliminating tool marks…

- High-Precision CNC Machining for Military Applications

Introduction to High-Precision CNC Machining in Military Applications The technical realm of high-precision Computer Numeric Control (CNC) machining is fast becoming integral to the military sector. This process, which relies…

- CNC Machining for the Automotive Industry: Steel vs. Aluminum Weight and Strength Analysis

CNC Machining and Its Use in the Automotive Industry: Steel vs. Aluminum CNC (Computer Numerical Control) machining, a method used to control machine tools via computers, has proven indispensable in…

- Using Acrylic in CNC Machining: Does It Offer Clear Advantages?

Introduction to CNC Machining and Acrylic CNC machining, an abbreviation for Computer Numerical Control, is a process utilized broadly in manufacturing where pre-programmed computer software directs the movement of factory…

- High-Speed Machining Techniques in CNC Machining Parts: Secrets to Enhanced Efficiency and Quality

High-speed machining (HSM) is an intriguing and evolving field within CNC machining. The term "high-speed" is relative and varies depending on the machining method, workpiece material, and tool material. Defining…