Introduction to Custom Aluminum Machining Services

Custom aluminum machining services is a specialized field within the manufacturing industry, offering bespoke solutions for producing high precision parts and components. These services involve processes such as milling, drilling, or turning raw aluminum pieces into meticulously designed units that cater to specific customer needs. The versatility of aluminum coupled with advanced technology in CNC machining has enhanced production efficiency extensively – especially within industries where intricacies, accuracy, light weight and strength are vital like the aerospace sector.

Key Components Involved

The key elements involved in custom aluminum machining include:

- The raw material: High-quality grade Aluminum stock. Lightweight yet strong, it produces durable machine parts.

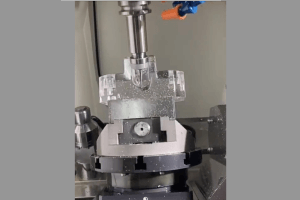

- Machining equipment: This includes computer numerically controlled (CNC) machines that guarantee reliability and precision down to micrometers, enabling complex geometries to be replicated flawlessly.

- Cutting tools: Made from resistant materials, they maintain their sharpness even under extreme pressures essentially offering clean and accurate cuttings.

- Lubrication/Cooling System: Ensures smooth operation by minimizing friction-induced heat damage, thereby enhancing lifespan of both tool as well as workpiece.

By integrating these four major components, custom aluminum machining achieves unparalleled effectiveness in generating lightweight yet robust components which significantly enhance performance efficiencies particularly in the Aerospace Industry.

Aerospace Components: Definition and Function

The term aerospace components refers to the various parts used in the design and construction of aircraft, spacecraft, satellites, and missiles. These could range from structural elements like wings or fuselage segments to complex mechanical systems such as propulsion devices and navigation controls. In essence, these components ensure the vehicle’s functionality, security, and performance during flight.

- Structural Elements: This includes vital parts like wings, tail assemblies, and fuselages that provide the primary structure and shape for any air or space vehicle.

- Propulsion Devices: Engines and propellers fall under this category. They generate thrust and power required for the vehicle’s movement.

- Control Systems: These inventory align with pieces like ailerons, elevators, and rudders which are fundamental for managing the direction and altitude of an aerial vehicle.

- Avionic equipment: They tag along all electronic equipment designed for use in aviation or space exploration, including communication devices, navigational aids, and collision-avoidance systems.

Altogether, these varied components form the basic construct of our modern aviation and space travel capabilities, requiring precise engineering and manufacturing.

Importance of Custom Aluminum Machining in Aerospace Industry

In the aerospace industry, custom aluminum machining plays a pivotal role in creating high-performance components. Its significance lies not only in its ability to provide lightweight and durable parts but also in offering high precision and optimal performance necessary for maintaining aircraft safety parameters. As such, manufacturers who offer these specialized services can effectively enhance production efficiency in aerospace construction.

Take, for example, the case of constructing an aircraft’s fuselage or engine parts. By utilizing cutting-edge technology and meticulous design strategies, custom aluminum machining renders it possible to create complex geometries that are critical to the functionality of aerospace components. This efficiency proves how indispensable these services have become in the arena of modern aviation manufacturing.

- Aircraft Fuselage: Customized machining allows the manufacture of uniquely shaped components while ensuring they retain strength and durability.

- Engine Parts: Due to their intricate designs and the need for heat resistance, custom-made parts crafted with exact specifications ensure maximum operational efficiency.

Understanding Production Efficiency in Custom Aluminum Machining Services for Aerospace Components

In the context of manufacturing, specifically custom aluminum machining for aerospace components, production efficiency is defined as the optimal use of resources (materials, labor, and machinery) to produce high-quality goods within a minimal time-frame. It involves managing the input costs while maximizing output quality and quantity. High efficiency rates are crucial in the manufacturing sector.

- A higher efficiency rate translates into increased productivity which directly impacts profitability. When companies utilize their resources effectively, fewer wastes are produced, leading to cost savings.

- Likewise, high efficiency improves turnaround times – getting products ready for market faster. This gives the manufacturer a competitive edge, especially important in the fast-paced aerospace industry. Speedy delivery enhances customer satisfaction and loyalty.

- Fostering efficiency also promotes reliance on innovative technology and procedures that streamline processes, improve product uniformity and reduce human error. An ideal example would be the incorporation of computer-aided designs (CAD) or automated machinery in custom aluminum machining services. Ensuring consistent quality and exact iterations of intricate component outputs reliably.

In conclusion, understanding and implementing measures for enhancing production efficiency play a vital role in propelling successful manufacturing operations, ensuring sustainability and competitiveness in the global aerospace industry arena.

How Does Custom Aluminum Machining Enhance Efficiency?

Custom aluminum machining enhances efficiency by leveraging the lightweight yet high-strength properties of aluminum to produce aerospace components with precision and reliability. The use of advanced CNC machining technology ensures the production of intricate and complex aluminum parts, contributing to the overall efficiency of the manufacturing process.

Potential Challenges in Custom Aluminum Machining

In the realm of custom aluminum machining, there are several potential challenges that can hinder efficiency. Fragmentation or chipping is a common issue largely due to the material’s softer nature and relatively low melting point. This could lead to inferior quality or faulty components. Another obstacle lies in controlling the dimensional accuracy of parts as aluminum tends to expand or contract significantly with fluctuations in temperature.

To navigate these hurdles effectively, possible solutions involve deploying suitable machinery with high-speed spindles and sharp tools for enhanced precision and decreased fragmentation. Applying consistent cooling processes might help contain thermal expansions, thus maintaining dimensional integrity. Furthermore, using appropriate feed rates and depth-of-cut parameters based on material characteristics can minimize errors while maximizing productivity.

Current Innovations and Developments in Custom Aluminum Machining Services

Innovative advancements have catapulted the efficiency of custom aluminum machining services to new levels. Developers are pushing boundaries, utilizing progressive technologies like 3D printing and advanced CNC automation which redefine production limits for aerospace components. For instance, these tools reduce manufacturing time by streamlining complex processes such as molding and cutting aluminum alloys.

- 3D Printing: This state-of-the-art technology bolsters the capability of creating intricate part geometries with a high level of outline precision, rendering traditional casting techniques obsolete.

- CNC Automation: Computer Numerical Control (CNC) automation has risen to prominence due to its propensity to perform repetitive tasks accurately without human involvement. It optimizes productivity while curbing labor costs and minimizing errors.

A vivid illustration of a trailblazing development is machine learning integrated into CNC systems. Machine learning enables smart automated adjustments on the go by recognizing patterns or anomalies which prevents defective outputs in aerospace components assembly lines. Hence, recent technological advances in custom aluminum machining services ensure optimum output quality, speed, and cost-efficiency needed in this demanding industry.

Conclusion

In summary, custom aluminum machining services play an invaluable role in enhancing the production efficiency of aerospace components. The adoption of this innovative technology allows manufacturers to create precise, high-quality parts that meet specific and rigorous design requirements for aerospace applications. Whether forging crucial engine elements or crafting intricate interior fittings,

- The versatility enabled by customizing machining processes accommodates a wide variety of designs and sizes.

- An increased rate of production, without compromising on quality, is guaranteed due to automation and cutting-edge equipment utilization.

- Sustainability objectives are met with resource-efficient operations reducing waste generation

Indeed, these benefits underscore how custom aluminum machining can boost performance, durability, and safety standards within the aerospace industry. Thus, it emerges as a critical player driving manufacturing excellence.

Other Articles You Might Enjoy

- Aluminum CNC Machining Service for Custom Parts

Aluminum CNC machining stands at the forefront of modern manufacturing, epitomizing precision, versatility, and efficiency. With its widespread applications across industries ranging from aerospace to automotive and beyond, aluminum CNC…

- CNC Machining for Aerospace: Aluminum 2024 vs. 6063

CNC Machining and Aerospace Manufacturing In the world of aerospace manufacturing, CNC (Computer Numerical Control) machining carries significant importance. As a modern machining method that leverages computer programming to dictate…

- CNC Machining for Aerospace Applications: Titanium vs. Aluminum Alloys

CNC Machining in Aerospace: An Introduction and Overview Computer Numerical Control (CNC) machining is a manufacturing process that utilizes software-directed machines to fabricate complex parts with high accuracy and repeatability.…

- Custom CNC Machining Services for Titanium Parts: Enhancing Aerospace and Medical Industries?

Custom CNC Machining in the Aerospace and Medical Sectors In response to the steady growth of both the aerospace and medical industries, increasingly sophisticated manufacturing techniques have become a necessity.…

- Aluminum vs. Brass in CNC Machining: Determining the Best Metal for Your Precision Components

Introduction to CNC Machining and Precision Components CNC machining, an acronym for Computer Numerical Control machining, is a manufacturing process in which pre-programmed computer software dictates the movement of machinery.…

- CNC Machining for Aerospace: Titanium Alloys vs. Aluminum - Performance and Cost Analysis

CNC Machining in the Aerospace Industry: An Introduction and Importance of Material Selection CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software directs the movement of…

Afrikaans

Afrikaans Albanian

Albanian Amharic

Amharic Arabic

Arabic Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Chichewa

Chichewa Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Corsican

Corsican Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Esperanto

Esperanto Estonian

Estonian Filipino

Filipino Finnish

Finnish French

French Frisian

Frisian Galician

Galician Georgian

Georgian German

German Greek

Greek Gujarati

Gujarati Haitian Creole

Haitian Creole Hausa

Hausa Hawaiian

Hawaiian Hebrew

Hebrew Hindi

Hindi Hmong

Hmong Hungarian

Hungarian Icelandic

Icelandic Igbo

Igbo Indonesian

Indonesian Irish

Irish Italian

Italian Japanese

Japanese Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korean

Korean Kurdish (Kurmanji)

Kurdish (Kurmanji) Kyrgyz

Kyrgyz Lao

Lao Latin

Latin Latvian

Latvian Lithuanian

Lithuanian Luxembourgish

Luxembourgish Macedonian

Macedonian Malagasy

Malagasy Malay

Malay Malayalam

Malayalam Maltese

Maltese Maori

Maori Marathi

Marathi Mongolian

Mongolian Myanmar (Burmese)

Myanmar (Burmese) Nepali

Nepali Norwegian

Norwegian Pashto

Pashto Persian

Persian Polish

Polish Portuguese

Portuguese Punjabi

Punjabi Romanian

Romanian Russian

Russian Samoan

Samoan Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sesotho

Sesotho Shona

Shona Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Somali

Somali Spanish

Spanish Sundanese

Sundanese Swahili

Swahili Swedish

Swedish Tajik

Tajik Tamil

Tamil Telugu

Telugu Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Uzbek

Uzbek Vietnamese

Vietnamese Welsh

Welsh Xhosa

Xhosa Yiddish

Yiddish Yoruba

Yoruba Zulu

Zulu