Unlock Precision with Our Custom Ceramic Parts Service

As pioneers in custom manufacturing, we proudly present our Custom Ceramic Parts Service, designed to elevate your projects in aerospace, electronics, medical, and beyond. Our expertise delivers ceramic components with unparalleled precision and resilience. Here’s what sets us apart:

Our Custom Ceramic Parts Service excels through advanced manufacturing techniques tailored for ceramics. We employ precision processes like injection molding, isostatic pressing, CNC machining, and sintering to produce components with exceptional accuracy and durability. Our facilities feature high-temperature kilns and multi-axis CNC machines, enabling us to craft intricate geometries and tight tolerances required in demanding applications. Whether it’s a small batch of prototypes or high-volume production, our expertise in green machining (pre-sintering shaping) and post-sintering finishing ensures superior surface quality and structural integrity.

Ceramics demand specialized knowledge, and we deliver. Our team is proficient in handling a broad range of ceramic materials, including alumina, zirconia, silicon carbide, and porcelain, each selected for its unique properties like heat resistance, electrical insulation, or wear resistance. We guide clients in choosing the ideal material for applications such as insulators, cutting tools, or biomedical implants.

Material | Key Properties | Common Applications |

Alumina | High hardness, thermal stability | Electronics, wear parts |

Zirconia | Toughness, biocompatibility | Medical implants, tools |

Silicon Carbide | Extreme heat/wear resistance | Aerospace, semiconductors |

Porcelain | Insulation, cost-effective | Electrical components |

We turn your concepts into reality with precision and flexibility. Our Custom Ceramic Parts Service offers comprehensive design support, using CAD tools to refine your specifications for manufacturability. From rapid prototyping with 3D printing to full-scale production, we adapt to your needs. Our engineers provide design-for-manufacturing (DFM) analysis, optimizing for ceramic-specific challenges like shrinkage during sintering.

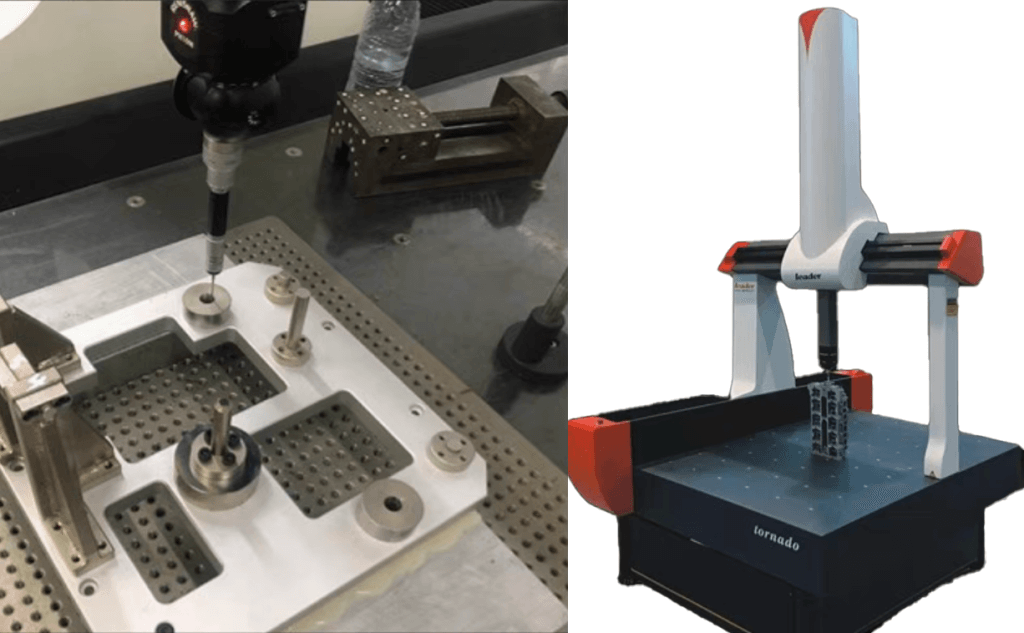

Quality defines our service. We uphold stringent standards, using advanced testing methods like X-ray diffraction, hardness testing, and dimensional inspection with CMMs to verify every ceramic part. Our ISO 9001-certified processes ensure consistency, while compliance with standards like ISO 13485 supports medical-grade applications.

Speed and scalability set us apart. Our streamlined production, powered by automated systems and real-time tracking, delivers ceramic parts on tight schedules—prototypes in days, production in weeks. We scale effortlessly from small runs to mass production, supported by robust supply chains and global shipping options.

You’re one step from the factory-direct price of part manufacturing services.