Transform Ideas with Our Custom Composite Material Parts Service

As innovators in custom manufacturing, we proudly offer our Custom Composite Material Parts Service, crafted to empower your projects in aerospace, automotive, marine, and more. Our expertise delivers lightweight, high-strength composite material parts tailored to excel in any environment. Here’s what makes us your ideal partner:

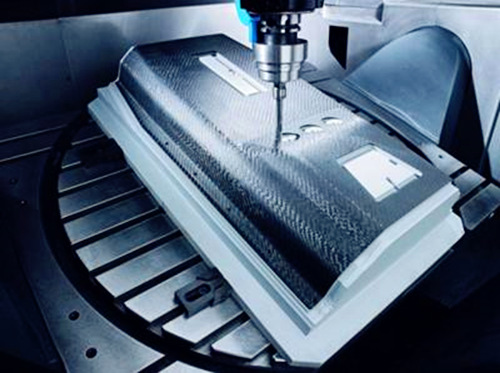

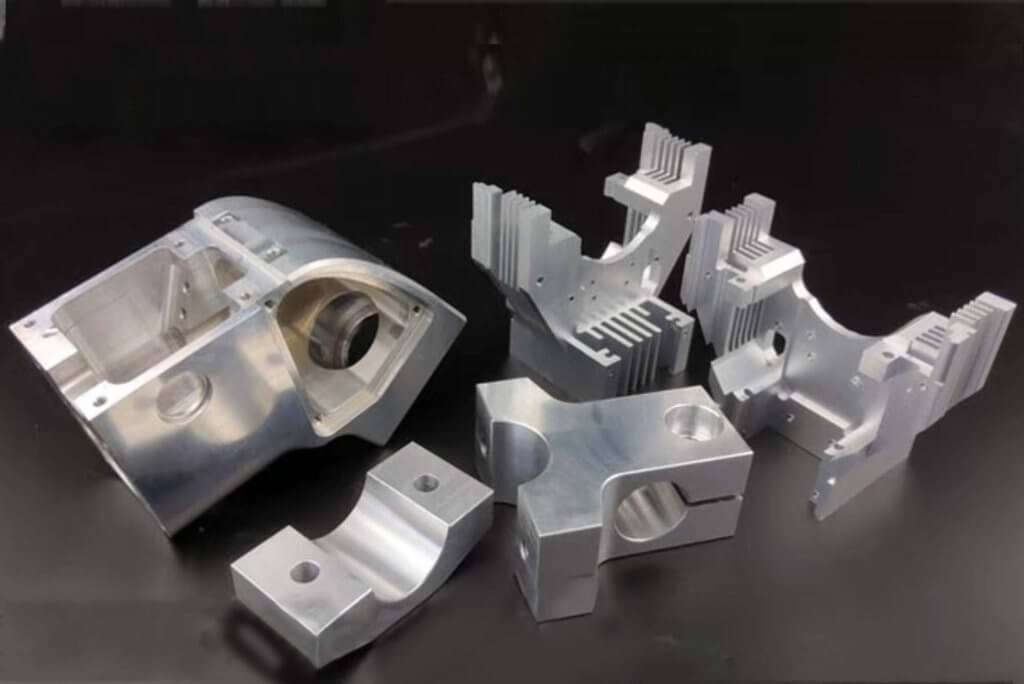

Our Custom Composite Material Parts Service excels with cutting-edge manufacturing techniques designed for composites. We utilize processes like resin transfer molding (RTM), vacuum bagging, compression molding, and filament winding to produce lightweight, high-strength parts. Our CNC machining and automated fiber placement systems ensure precision in complex geometries, while our curing ovens optimize material properties through controlled heat and pressure. From prototypes to large-scale production, we tailor our methods to meet your specifications, delivering parts with exceptional structural integrity and surface finish.

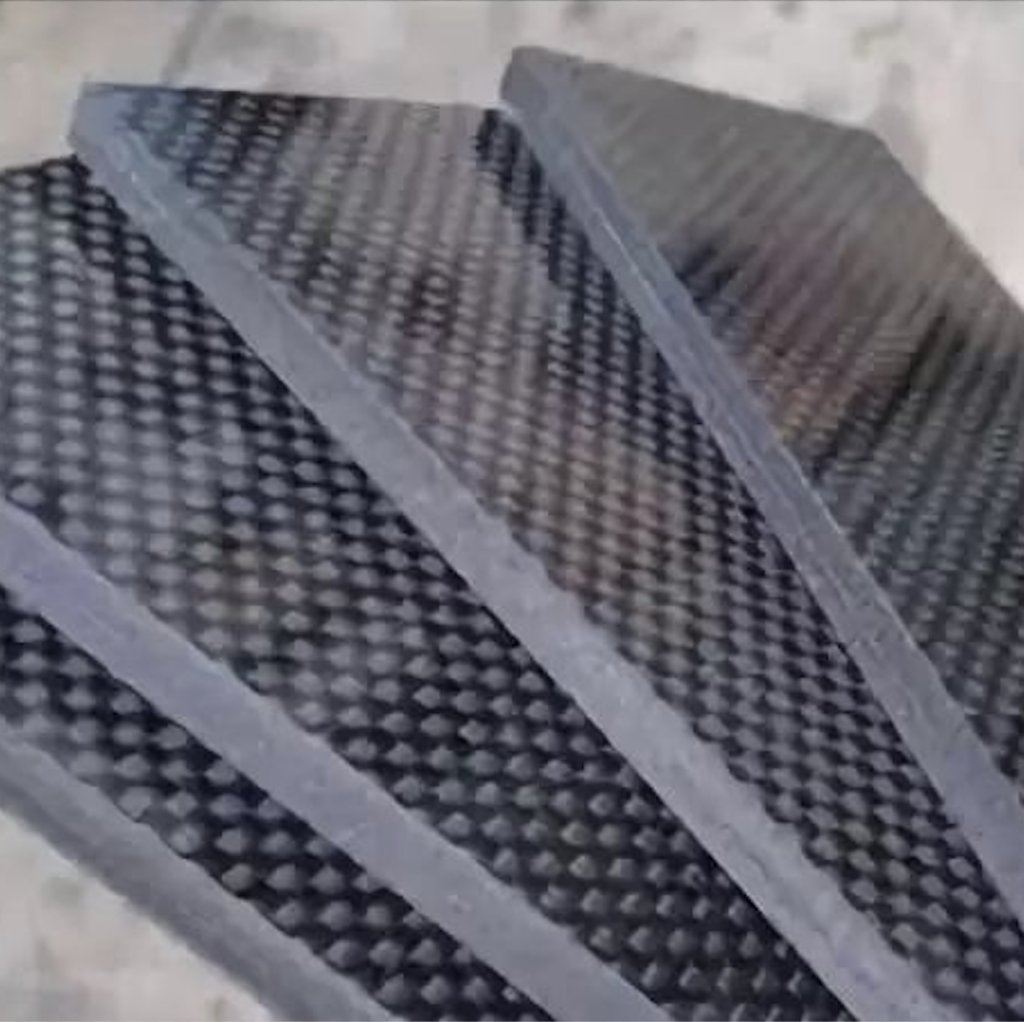

Composites demand specialized knowledge, and we deliver exceptional proficiency across an extensive range. Our team excels in a wide array of materials, including carbon fiber, fiberglass, aramid (Kevlar), hybrid composites, as well as advanced metal matrix composites like Alumina-Reinforced Metal Matrix Composites and Silicon Carbide Reinforced Aluminum Matrix Composites (SiC/Al). We guide clients in selecting the optimal composite for applications such as aerospace structures, automotive panels, marine hulls, or high-performance industrial components, ensuring the best strength-to-weight ratio, stiffness, or durability.

Material | Key Properties | Common Applications |

Carbon Fiber | High strength, lightweight | Aerospace, sports gear |

Fiberglass | Cost-effective, durable | Marine, automotive parts |

Aramid (Kevlar) | Impact resistance, flexibility | Protective gear, aerospace |

Hybrid Composites | Balanced properties | Custom structural parts |

Alumina-Reinforced Metal Matrix Composites | High hardness, wear resistance | Industrial tools, wear parts |

Silicon Carbide Reinforced Aluminum Matrix Composites (SiC/Al) | Lightweight, heat resistance, strength | Aerospace components, brakes |

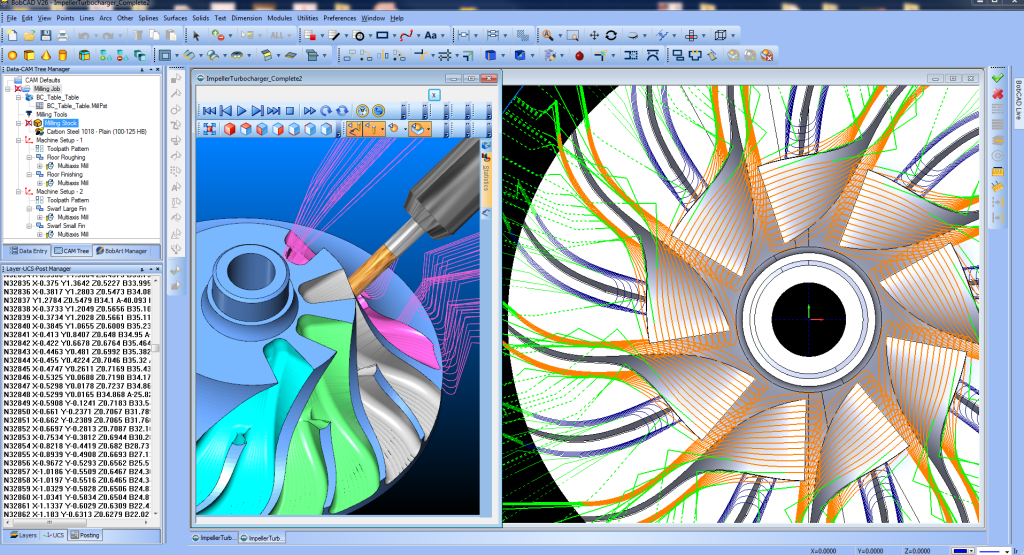

We bring your vision to life with precision and flexibility. Our Custom Composite Material Parts Service offers comprehensive design support, leveraging CAD software and finite element analysis (FEA) to optimize part performance. From rapid prototyping with 3D printing to full production, we adapt to your needs. Our design-for-manufacturing (DFM) expertise addresses composite-specific challenges like layup optimization and curing shrinkage.

Quality is our priority. We enforce rigorous standards, using non-destructive testing (NDT), ultrasonic inspection, and mechanical testing to validate every composite part. Our ISO 9001-certified processes guarantee consistency, while compliance with standards like AS9100 (aerospace) supports specialized applications.

en

en