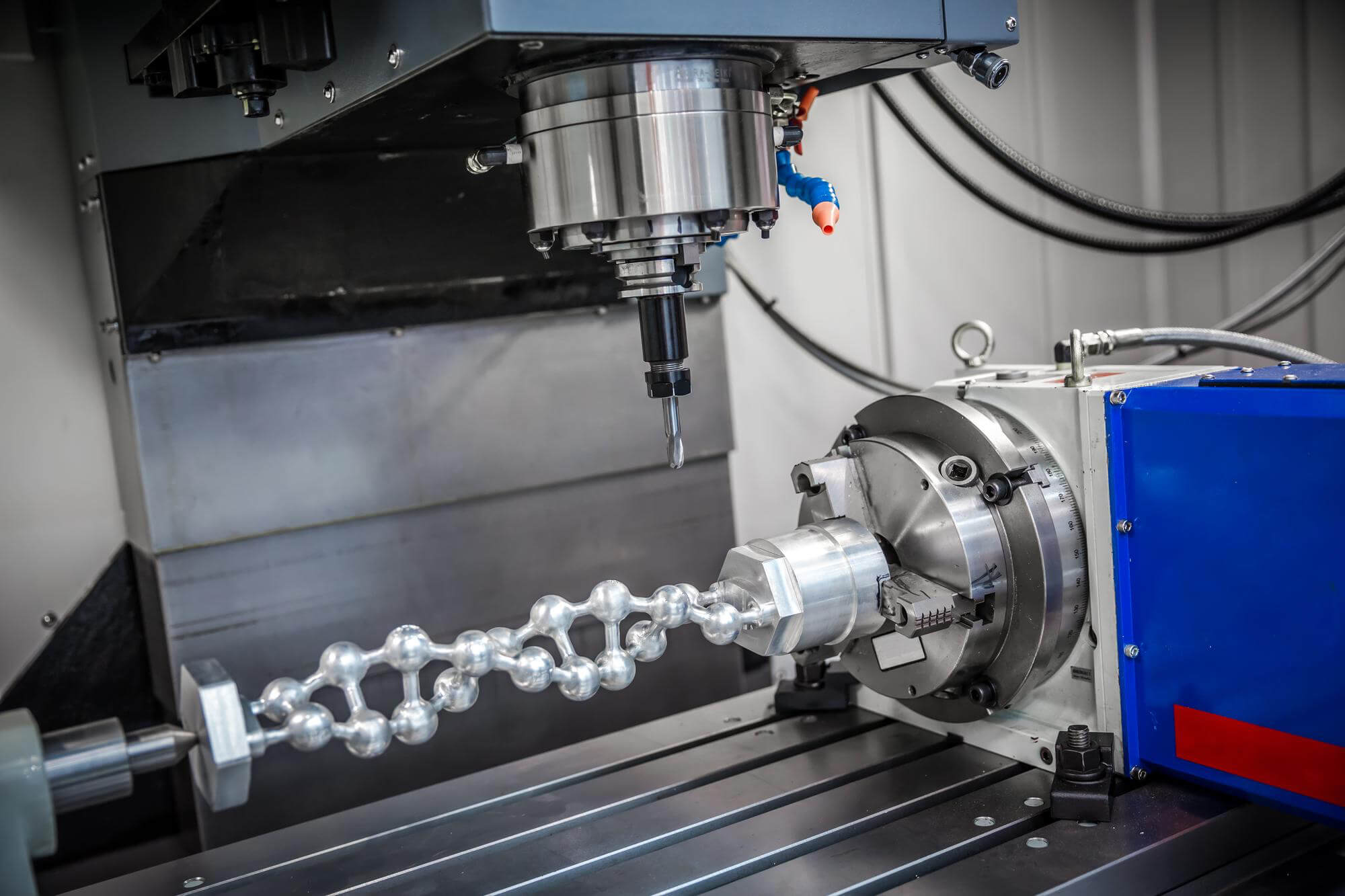

Walking into a modern machine shop, you’re often greeted by a vast array of shiny, high-tech CNC machines. These marvels of engineering are at the heart of precision manufacturing, churning out everything from intricate aerospace components to everyday household items. But to truly appreciate the capabilities of these machines, you need to dive into the details: the features and specifications that make them tick.

The Importance of Understanding Machine Features

CNC machines are often showcased in glossy brochures filled with high-quality images and impressive specifications. While these brochures are designed to attract potential customers, they also contain a wealth of technical information that is crucial for anyone looking to optimize their use of these machines. By understanding the features and specifications of a CNC machine, you can make informed decisions about programming, tooling, and overall operation.

Typical Specifications of a CNC Lathe

Let’s take a closer look at the typical specifications of a two-axis slant-bed horizontal CNC lathe. These specifications provide a snapshot of the machine’s capabilities and limitations.

| Specification | Description |

|---|---|

| Number of Axes | 2 (X and Z) or 3 (X, Z, and C) |

| Max Turning Diameter | 560 mm (22.05 in) |

| Max Turning Length | 550 mm (21.65 in) |

| Spindle Bore Diameter | 85 mm (3.34 in) |

| Max Bar Stock Diameter | 71 mm (2.79 in) |

| Number of Tools | 12 |

| Square Tool Shank Size | 25 mm (1 in) |

| Round Tool Size | Ø 40 mm (Ø 1.57 in) |

| Tool Change Index Time | 0.15 s |

| X-Axis Travel | 222 mm (8.75 in) |

| Z-Axis Travel | 635 mm (25 in) |

| X-Axis Rapid Traverse Rate | 16,000 mm/min (629 in/min) |

| Z-Axis Rapid Traverse Rate | 24,000 mm/min (944 in/min) |

| Cutting Feed Rate | 0.01 ~ 500 mm/r (0.0004 ~ 19.68 in/min) |

| Chuck Size | 254 mm (10 in) |

| Spindle Motor | AC 15/11 kW (20/14.7 hp) |

| Spindle Speed Range | 35 ~ 3,500 rpm |

| Minimum Input Increment | 0.001 mm (0.00004 in) |

| Powered Tools | 12 |

| Powered Tool Speed Range | 30 ~ 3,600 rpm |

| Milling Motor | AC 3.7/2.2 kW (5/2.95 hp) |

| Collet Size | 1 ~ 16 mm (0.04 ~ 0.63 in) |

| Tapping Size | M3 ~ M16 (5/8 in) |

Understanding these specifications helps operators and programmers know exactly what their machine can handle. For instance, knowing the maximum turning diameter and length ensures that the workpiece fits within the machine’s capacity, while the spindle speed range affects the type of materials that can be effectively machined.

Key Machine Features and Their Importance

Axes and Movement: The number of axes determines the complexity of operations the machine can perform. Most CNC lathes operate with two main axes (X and Z), but additional axes like C or Y can enable more complex machining tasks such as milling, drilling, and even 3D contouring.

Spindle and Chuck: The spindle is the heart of the machine, rotating the workpiece with precision. The chuck holds the workpiece firmly in place. The spindle speed and bore diameter are critical for determining the types and sizes of materials the machine can process.

Tooling System: The number and type of tools a machine can hold directly impact its versatility. Quick tool change systems and the ability to use various tools (square, round, powered) enhance productivity and reduce downtime.

Feed Rates and Travel: Rapid traverse rates for the X and Z axes indicate how quickly the machine can position the tool, which affects overall cycle time. The cutting feed rate is essential for determining the quality and precision of the finished part.

Motor Power and Speed: The power of the spindle and milling motors determines the machine’s ability to cut through different materials efficiently. Higher speeds are suitable for softer materials, while more power is needed for tougher materials.

Control Features

Control features in CNC machines are what set them apart from manual machines. They allow for precision, repeatability, and automation. Key control features include:

Constant Surface Speed (CSS): This feature adjusts the spindle speed to maintain a constant cutting speed at the tool’s surface, enhancing the quality of the finish and prolonging tool life.

Programming Modes: Absolute programming (X, Z, C) and incremental programming (U, W, H) provide flexibility in creating complex tool paths and operations.

Thread Cutting Capabilities: Advanced controls allow for various thread shapes, including tapered and round threads, expanding the machine’s application range.

Tool Selection and Feed Rate Control: Precise control over tool selection and feed rates ensures optimal cutting conditions for different materials and operations.

Practical Tips for Maximizing CNC Machine Potential

- Regular Maintenance: Keeping the machine in top condition ensures longevity and precision. Regularly check and maintain key components like the spindle, chuck, and tool holders.

- Optimize Programming: Use simulations to test and optimize CNC programs before running them on the machine. This helps catch potential errors and improve efficiency.

- Tool Management: Efficiently manage and organize tools to minimize changeover times and ensure that the right tool is always available for the job.

- Monitor Performance: Keep track of machine performance metrics to identify and address issues before they lead to significant downtime.

- Training: Ensure that all operators are well-trained in using the machine and understanding its features and specifications. This knowledge is crucial for maximizing the machine’s potential.

Understanding the features and specifications of CNC machines is crucial for optimizing their use. From the number of axes and spindle power to tool change systems and control features, each aspect plays a vital role in the machine’s performance and the quality of the parts produced. By decoding these details, operators and programmers can harness the full potential of their CNC machines, leading to greater efficiency, precision, and innovation in manufacturing.

Other Articles You Might Enjoy

- Applications and Advantages of Bronze CNC Machining

1. Introduction: The Enduring Allure of Bronze in CNC Machining In this opening section, we explore the timeless appeal of bronze as a material for CNC machining. From its rich…

- Innovative CNC Machining for Complex Surgical Tools

Introduction to CNC Machining and its Significance in Surgical Tools Manufacturing CNC machining, an acronym for Computer Numerical Control machining, plays a significant role in the manufacturing world. Being an…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Diving into Vertical CNC Machining Centers: From Programming to Specifications

When you step into a machine shop, the hum of CNC machines is a familiar sound. Among these, the vertical CNC machining center is a workhorse, particularly when it comes…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Tapping Methods in CNC Machining

Classification and Characteristics of Tapping in CNC Machining Tapping, using taps to machine threaded holes, is the most commonly used method for creating threaded holes. It is mainly suitable for…