Detailed Explanation of Pneumatic, Hydraulic, and Transmission Components

Welcome to the world of mechanical design. In this article, we will explore pneumatic systems, hydraulic systems, and their common transmission components. Through step-by-step exploration, we will uncover the mysteries of these mechanical parts.

Pneumatic Systems and Components

Pneumatic transmission technology uses compressed air as the medium to achieve the transmission and control of mechanical mechanisms. It is energy-efficient, high-performing, pollution-free, low-cost, safe, reliable, and has a simple structure. It is widely used in various equipment and production lines.

Pneumatic Source Treatment Components

- Air Filter: Removes impurities and moisture from compressed air, ensuring the normal operation of the pneumatic system.

- Pressure Regulator: Adjusts and stabilizes the output compressed air pressure.

- Oil Mist Lubricator: Atomizes lubricating oil and mixes it into the compressed air to lubricate the moving parts in the pneumatic system.

Pneumatic Control Components

- Solenoid Valve: Controls the opening and closing of air circuits through electrical signals, with various types such as two-way two-position, two-way three-position, two-way five-position, and three-way five-position.

- Flow Control Valve: Adjusts the flow of compressed air to control the movement speed of pneumatic actuators.

Pneumatic Actuators

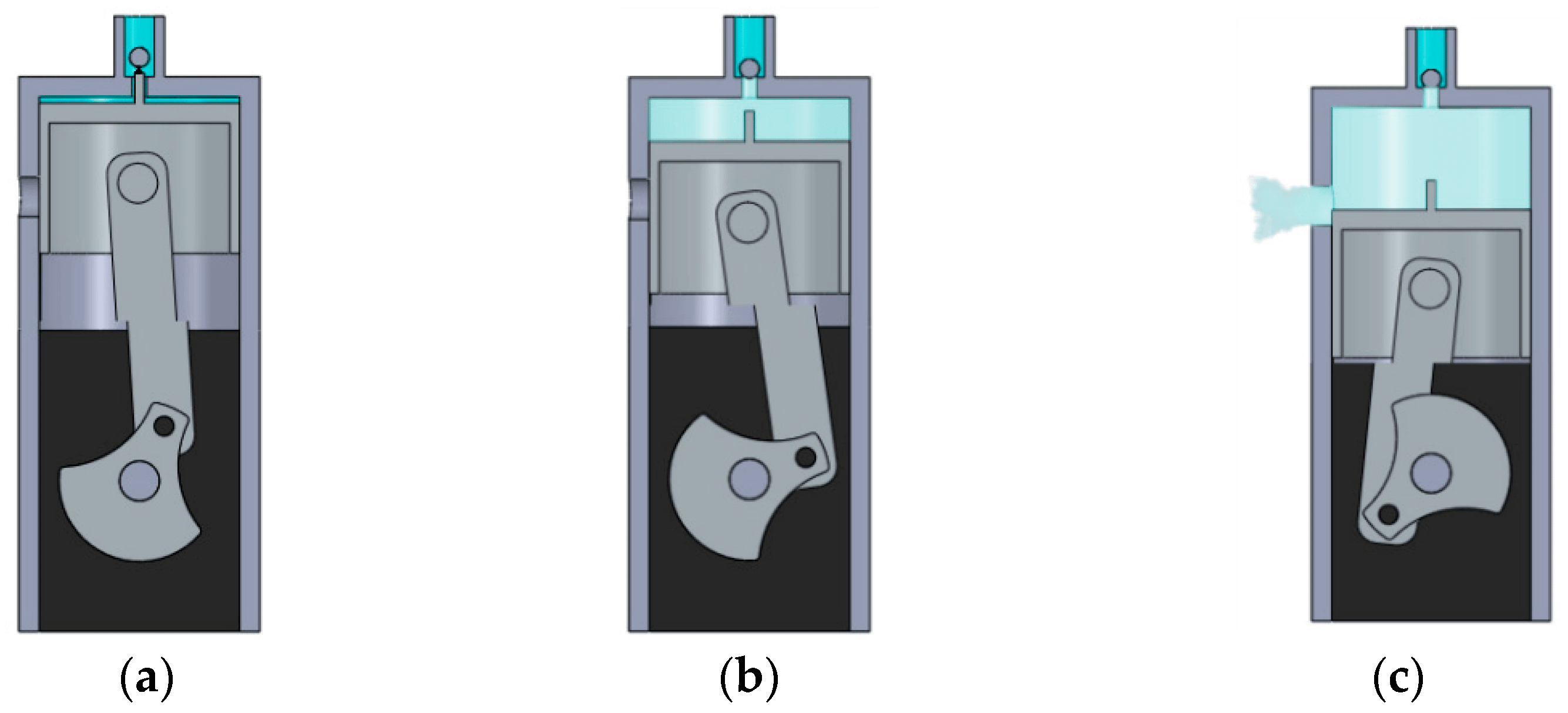

- Cylinder: Converts the energy of compressed air into mechanical energy, achieving linear or rotary motion. Types include single-axis cylinders, double-axis cylinders, rodless cylinders, and more.

- Pneumatic Motor: Converts the energy of compressed air into rotational motion, commonly used to drive rotating mechanisms.

Pneumatic Accessories

- Cushioning Device: Absorbs the impact force at the end of cylinder movement, extending the service life of equipment.

- Air Pipes and Fittings: Connects various pneumatic components and transmits compressed air.

Common Brands

Popular brands in the domestic market include FESTO (Germany), SMC (Japan), Airtac (Taiwan), among others. These brands generally adopt European ISO and Japanese JIS standards, making products of the same standard interchangeable.

Hydraulic Systems and Components

Hydraulic systems use hydraulic pumps to convert the mechanical energy of motors into the pressure energy of liquids. This pressure energy is transmitted through various control valves and pipelines and is converted back into mechanical energy by hydraulic actuators to drive work mechanisms.

Hydraulic System Components

- Power Source: Electric motors and hydraulic pumps provide the necessary hydraulic energy for the system.

- Actuators: Hydraulic cylinders and hydraulic motors convert liquid pressure energy into mechanical energy.

- Control Valves: Includes pressure control valves, flow control valves, and direction control valves to regulate the pressure, flow, and direction of hydraulic oil.

- Hydraulic Accessories: Tanks, filters, heat exchangers, and more ensure the normal operation of the hydraulic system.

- Hydraulic Working Medium: Various hydraulic oils act as the energy transfer medium, also providing lubrication and cooling (types include 32#, 46#, 68#).

Comparison Between Hydraulic and Pneumatic Systems

Both hydraulic and pneumatic systems use pressurized fluid media to transmit force. Pneumatic systems use compressed air, while hydraulic systems use hydraulic oil. Pneumatic systems are generally open-loop, while hydraulic systems are closed-loop.

Common Sensors

Sensors are essential components in industrial automation control, acting as the “senses” of non-standard equipment systems. They detect various physical quantities and transmit signals to control devices. There are many types of sensors depending on the detection object.

Common Position Sensors

- Limit and Travel Switches: Detect positions through mechanical contact, with simple structures but short lifespans.

- Proximity Sensors: Such as Hall sensors, reed switches, inductive and capacitive proximity sensors for non-contact detection.

Other Types of Sensors

- Displacement Sensors: Measure linear or angular displacement.

- Force Sensors: Measure force magnitude or object weight.

- Pressure Sensors: Measure the pressure of gases or liquids.

- Temperature Sensors: Measure temperature.

Rolling Bearings and Linear Bearings

Rolling bearings are crucial components in modern machinery, primarily used to support rotating bodies and reduce friction. Linear bearings, on the other hand, provide guidance and load-bearing for axial movement.

Rolling Bearing Structure

- Inner Ring: Typically fits tightly with the shaft and rotates with it.

- Outer Ring: Fits with the bearing housing or mechanical component housing, providing support.

- Rolling Elements: Arranged evenly between the inner and outer rings by a cage, determining the bearing’s load capacity.

- Cage: Separates the rolling elements and guides them to move in the correct track.

Types of Linear Bearings

Linear bearings mainly include sliding friction linear bearings and rolling friction linear bearings. Sliding friction bearings often use bronze sleeves, graphite bronze sleeves, or engineering plastic sleeves, while rolling linear bearings are more commonly used in practical applications.

Table: Common Types of Rolling Bearings and Linear Bearings

| Type | Main Function | Example |

|---|---|---|

| Radial Bearings | Bear radial loads | Deep Groove Ball Bearings |

| Angular Contact Bearings | Bear combined loads | Tapered Roller Bearings |

| Thrust Bearings | Bear axial loads | Thrust Ball Bearings |

| Linear Bearings | Guide axial movement | Sliding Friction Bearings |

Linear Guides

Linear guides achieve rolling friction through the rotation of rolling elements, significantly reducing friction coefficients. They are mainly used to support and guide moving parts for linear reciprocating motion and can maintain high precision under heavy loads.

Linear Guide Brands

Popular brands on the market include THK, MISUMI, and IKO from Japan, and HIWIN and ABBA from Taiwan. Among them, HIWIN is known for its high cost-performance ratio and is widely used in non-standard automation equipment.

By gradually understanding pneumatic and hydraulic systems and their transmission components, we can better appreciate the importance and complexity of these mechanical systems in practical applications. I hope this article provides you with valuable information and helps you further your journey in mechanical design.

Other Articles You Might Enjoy

- Detailed Explanation of the Metal Cutting Process

Basic Knowledge of Metal Cutting Detailed Explanation of the Metal Cutting Process Basic Knowledge of Metal Cutting When cutting metal, we encounter various cutting phenomena. Understanding these phenomena helps improve…

- Detailed Explanation of Surface Quality in Machining

Surface quality in machining not only affects the appearance of the product but also has a significant impact on its performance, reliability, and durability. Studying and controlling surface quality can…

- Detailed Explanation of Surface Quality in Machining

Surface quality in machining not only affects the appearance of the product but also has a significant impact on its performance, reliability, and durability. Studying and controlling surface quality can…

- Precision Engineering: Bead Blasting for Aluminum Components

In the realm of precision engineering, achieving impeccable surface quality and dimensional accuracy is paramount. Bead blasting technology has emerged as a versatile solution for refining aluminum components, offering meticulous…

- CNC Machining of Composite Materials: Challenges and Opportunities?

Introduction to CNC Machining and Composite Materials CNC, or Computer Numerical Control machining refers to a manufacturing process where pre-programmed computer software dictates the movement of factory machinery and tools.…

- Revolutionizing Renewable Energy with CNC Machined Components

Introduction to Renewable Energy Rewindable energy is inherently replenished on a human timescale, meaning it harnesses natural elements that naturally renew themselves. These sources traditionally include sunlight, wind, rain, tides,…