Basic Knowledge of Metal Cutting

Detailed Explanation of the Metal Cutting Process

Basic Knowledge of Metal Cutting

When cutting metal, we encounter various cutting phenomena. Understanding these phenomena helps improve processing efficiency and workpiece quality. The three most important concepts in the metal cutting process are chip formation, cutting force, and cutting power.

Chip Formation and Types

Metal cutting is essentially a process of extrusion. Under the extrusion action in front of the tool, the metal undergoes plastic shear slip deformation, and then is cut off from the workpiece to form chips. Depending on the material being processed and the cutting conditions, the shapes of the chips will vary, and they can be categorized into four main types:

- Continuous Chips

These are typically produced when machining ductile metal materials, such as steel. Under conditions of small cutting thickness, high cutting speed, and large tool rake angle, the material does not undergo full deformation. Therefore, the force and heat generated during cutting are relatively small, making the cutting process smooth and resulting in a low surface roughness of the machined surface. - Segmented Chips

Also known as shear localized chips, these occur when machining harder ductile metal materials at low cutting speeds, large cutting thicknesses, and large tool rake angles. Due to the large amount of slip during shear deformation, work hardening occurs, increasing the shear stress locally to the material’s fracture strength. This causes large fluctuations in cutting force and results in a rougher machined surface. - Discontinuous Chips

These are produced when cutting materials with poor plasticity, especially at very low cutting speeds. The chips break completely along the shear plane, appearing in segmented forms. - Fragmented Chips

Mainly formed when machining brittle materials like cast iron and bronze. The cutting heat and force are concentrated near the main cutting edge and tool tip, causing easy tool wear, vibration, and affecting the quality of the workpiece surface.

Factors Affecting Cutting Deformation

Several factors influence cutting deformation, including the material of the metal, the rake angle of the tool, cutting thickness, and cutting speed. Changes in these factors directly affect the stability of the cutting process and the quality of the workpiece.

Built-up Edge (BUE)

Built-up edge is a common physical phenomenon during cutting, especially when cutting ductile metals like steel and aluminum alloys. The formation of built-up edge affects the cutting process in the following ways:

- Protecting the Tool: Built-up edge covers the cutting edge, acting as a protective layer.

- Increasing Rake Angle: Reduces cutting deformation and cutting force.

- Causing Vibration: The cyclic formation and detachment of the built-up edge cause fluctuations in cutting force, leading to vibration.

- Increasing Surface Roughness and Tool Wear: The detachment of the built-up edge leaves behind fragments on the workpiece surface, increasing roughness and tool wear.

To avoid built-up edge, consider the following measures:

- Control cutting speed to avoid speeds that promote built-up edge formation.

- Increase the tool rake angle to reduce cutting deformation.

- Use cutting fluids with good lubrication to reduce friction.

- Employ suitable heat treatment methods to increase the hardness of the workpiece material and reduce work hardening.

Cutting Force and Cutting Power

Cutting Force

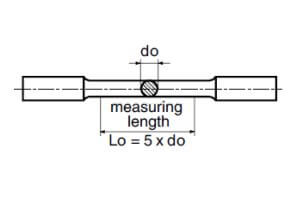

Cutting force is the force generated by the tool during the cutting process. The total cutting force can be decomposed into three components:

- Cutting Force (Fc): The projection of the total cutting force in the main movement direction.

- Feed Force (Ff): The projection of the total cutting force in the feed direction.

- Radial Force (Fp): The component of the total cutting force perpendicular to the workpiece plane.

Among these components, cutting force (Fc) has the most significant impact on machine power consumption and is crucial for designing and verifying the power and rigidity of the machine tool.

Cutting Power

Cutting power is the energy required during the cutting process. It can be calculated using the following formula:

[ Pm = Fc \times vc + Ff \times vf ]

where Fc is the cutting force, vc is the cutting speed, Ff is the feed force, and vf is the feed speed.

The motor power of the machine tool (PE) can be calculated by dividing the cutting power (Pm) by the transmission efficiency (η), which is generally between 0.75 and 0.85.

Conclusion

Every aspect of the metal cutting process, from chip formation to the calculation of cutting force and cutting power, significantly impacts the final machining results. Understanding these basic concepts helps optimize cutting parameters, improve processing efficiency, and ensure the quality of the workpiece. Below is a data table on the decomposition of cutting force to help better understand these concepts.

Cutting Force Decomposition Data Table

| Cutting Parameter | Value | Description |

|---|---|---|

| Cutting Force (Fc) | 200 N | Projection of the total cutting force in the main movement direction |

| Feed Force (Ff) | 50 N | Projection of the total cutting force in the feed direction |

| Radial Force (Fp) | 30 N | Component of the total cutting force perpendicular to the workpiece plane |

By understanding and mastering this knowledge, we can better handle the challenges encountered in the metal cutting process, improve processing efficiency, and ensure the quality of the workpiece.

Other Articles You Might Enjoy

- Beyond Cutting: Exploring the Multifaceted CNC Machining Process

1. Introduction: Unveiling the Layers of CNC Machining In this introductory section, we peel back the layers of the CNC machining process, going beyond the traditional understanding of cutting. It…

- Comprehensive Guide to Metal Cutting Tools

In modern mechanical manufacturing, metal cutting processes are the most widely used methods, accounting for over 50% of the total workload in mechanical manufacturing. Whether it's a conventional lathe, an…

- From Vision to Reality: CNC Machining for Custom Furniture Design

Introduction to CNC Machining in Custom Furniture Design The advent of computer numerical control (CNC) machining has revolutionized the field of custom furniture design, allowing precise and intricate patterns to…

- Precision CNC Machining Services: Reliable Solutions in Stainless Steel

Precision CNC Machining: An Essential Manufacturing Tool Precision CNC machining is a modern manufacturing process that uses detailed, digitized designs to guide complex machinery. Through the use of a Computer…

- Metal Cutting Machine Tool Design: Exploring the Fascinating World of Metal Processing

Overview of Metal Cutting Machine Tools Metal cutting machine tools are machines that use tools or abrasives to cut metal workpieces. They are known as the "mother machines," the machines…

- Understanding the Process of Bead Blasting in CNC Machining(laser cutting cnc Dinah)

Bead blasting is a crucial process within the realm of Computer Numerical Control (CNC) machining. It's an integral operation that gives metal parts their final polished appearance ready for use…