With the evolution of manufacturing technology, precision machining has advanced beyond conventional methods. Computer Numerical Control (CNC) machining, for instance, holds an irreplaceable position in modern production processes. One technique that is often used to refine and sophisticate these machined parts is bead blasting.

Bead blasting can be defined as a process where high-pressure streams of glass or ceramic beads are directed towards a surface to clean or enhance its mechanical attributes. In the context of CNC machining, it becomes an integral finishing step that contributes greatly to the product’s overall appearance and performance.

Firstly, let us understand what CNC machining entails. This is essentially an automated process which manipulates tools around three to five axes, holding the material workpiece in place while cutting it into the desired shape. A vast number of materials can be CNC machined including but not limited to steel, aluminium, brass, copper, and several types of plastic.

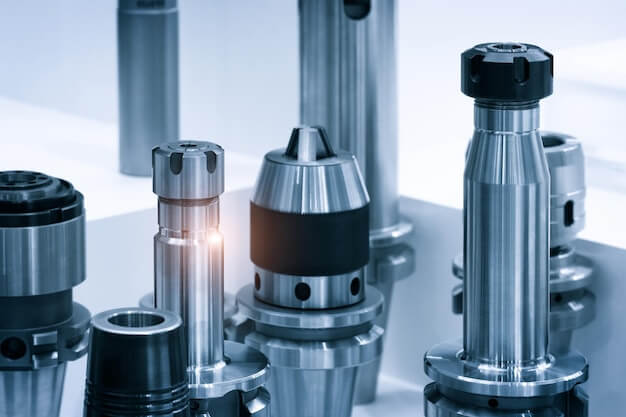

There are various types of CNC machines each specialized suited for specific jobs – Mills for milling operations where rotary cutters remove material from a work part; Lathes for turning operations involving the removal of material from a rotating work part; and routers designed for cutting shapes on soft materials. The final output quality depends highly upon precise programming and operational control by the operator despite being largely automatic.

After the machining process, it’s crucial to add finishing touches to the fabricated components using techniques like bead blasting. But why bead blasting?

To start with, bead blasting effectively improves the aesthetic appeal of the machined surfaces. It imparts a uniform matte finish making them visually appealing enough even for applications where aesthetics play an important role besides functionality.

It aids in contamination prevention achieved through eradicating residual surface materials such as scaling, rust, or previous coatings that may harbor contaminants detrimental to later use and longevity of the component. By stripping these residues, bead blasting effectively reduces potential contamination traps resulting in cleaner end products.

Bead blasting also helps in reducing part distortions. The non-destructive nature of this process ensures that there isn’t any change to the underlying substrate structure or its integrity. It conserves the original contour and dimensions of the part while providing a smooth finish free from tiny defects that may interfere with part functionality.

To carry out bead blasting, especially in CNC machining, manufacturers use specialized machines known as blast cabinets. These devices generate high-pressure air necessary for propelling the beads against surfaces of the workpiece. An operator fills the machine with the dedicated blasting media (beads) and the machined parts are placed inside. The cabinet is then securely shut before launching the blasting operation, operated manually or computer-assisted.

Depending upon the requirements like desired surface roughness, different grades of bead materials varying in sizes, shapes, and hardness can be used. It might involve a few trials to arrive at an optimal combination, but once found, it guarantees repetitive quality results across multiple parts components and production batches.

In conclusion, CNC machining forms a vital component within manufacturing technology, producing highly precision-based outcomes. When complemented with finishing processes such as bead blasting, it results in enhanced aesthetic appeal, reduced risk of contamination, minimized distortion, delivering top-tier finished parts suitable for various industries ranging from medical to automotive sectors. Undoubtedly, the incorporation of bead blasting remains invaluable to optimizing and maximizing the benefits of CNC machining.

Other Articles You Might Enjoy

- CNC Machining of Rare Earth Metals: Applications and Material Characteristics

CNC Machining and Rare Earth Metals: An Overview CNC machining, short for Computer Numerical Control machining, is a manufacturing process where pre-programmed computer software dictates the movement of factory tools…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…