Introduction to CNC Machining in Aerospace Assemblies

Computer Numerical Control (CNC) machining represents a significant technological development playing a notable role in the creation of complex aerospace assemblies. CNC machining utilizes computer systems to precisely control the movement and operation of machines. The associated automation reduces human intervention, thus minimizing errors whilst maximizing precision, efficiency, and repeatability. Specifically in aerospace assemblies, CNC machining enables production of intricate parts with exceptional accuracy.

- Critical components of spacecraft or aircraft like engine parts, landing gear, and structural elements are produced using CNC machining because it provides unrivaled precision which is essential for their functionality.

- The system assures repeatable quality on mass-produced parts—a fundamental requirement in the highly demanding aviation industry.

- Due to the deterministic nature of CNC machining, prototyping is fast-tracked accelerating product development cycles—a crucial aspect given the rapid pace at which aerospace technology advances.

The Current State of CNC Machining for Aerospace Assemblies

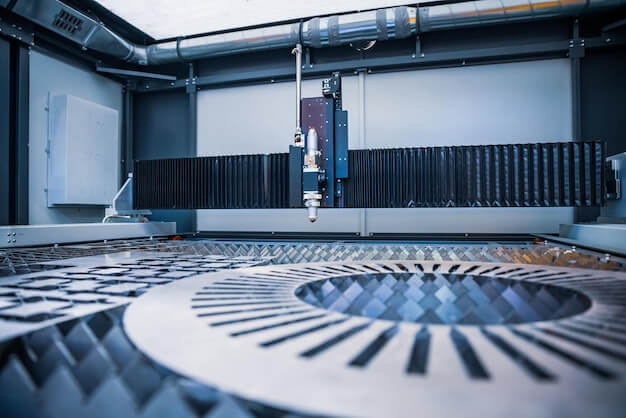

The current landscape of Computer Numerical Control (CNC) machining in aerospace manufacturing is primarily defined by traditional methods, which employ the use of multi-axis machines to achieve complex jurisdictional work. These processes involve converting a digital model into numerical coordinates capable of guiding drilling, milling and cutting operations on highly durable materials like titanium alloys or high-temperature-resistant thermoplastics prevalent in the aerospace industry.

However, these conventional processes face multiple challenges including long lead times due to the intricacy of components, substantial material waste during processing, and the need for successive operations to produce facets with varying geometries. More so, limitations related to tool reach can also pose difficulties when machining deep cavities in complex assemblies necessitating frequent part handling, resulting in more time consumption and potential deviation from dimensional accuracy.

How Technology is Revolutionizing CNC Machining for Aerospace Assemblies:

- Aerospace CNC machining is undergoing a revolution with the integration of advanced technology, allowing for the production of complex aerospace assemblies with unprecedented precision and efficiency.

- This article provides insights into how technology is revolutionizing CNC machining for aerospace assemblies. online CNC service

- The utilization of 5-axis CNC machining, precision machining, and advanced finishing techniques is transforming the manufacturing process, enabling the creation of intricate and high-performance aerospace components.

Impact of Advanced CNC Techniques on Complex Aerospace Assemblies

The advent of advanced Computer Numerical Control (CNC) techniques has significantly impacted the production and accuracy of complex aerospace assemblies. Updated machining strategies and tooling innovations have simplified previously challenging aspects, allowing for more streamlined production processes.

Intricate geometries can be accurately cut with precision alleviating likelihoods of human errors. Consequently, this also permits quicker turn-around times resulting in faster time-to-market and reduced operational costs. For instance, when manufacturing a specific though intricated component like an engine turbine bladed disk (‘blisk’), multiple axes CNC milling machines are employed. These cutting-edge machinery offers utmost accuracy even with intricate blade profiles, thereby tremendously boosting production efficiency and ensuring that aerospace parts comply strictly to dimensional and quality standards.

Benefits Achieved from Revolutionized CNC Machining

With the advent of revolutionized CNC machining in aerospace assemblies, there have been significant benefits; both for manufacturers and end users. From a manufacturing perspective, one of the key advantages is cost reduction; as precision engineering minimizes material waste during production. It not only mitigates financial implications but also solidifies sustainability efforts. Moreover, time-saving is another compelling benefit, with automated CNC machines delivering components at a much quicker pace compared to traditional methods.

- Enhanced overall product quality: High accuracy levels offered by revolutionary CNC machines ensure fewer errors, resulting in superior quality products.

- Safer, more reliable aircrafts for end-users: The improved structural integrity due to precise CNC engineering yields safer and more reliable aircraft assemblies, exponentially boosting consumer trust.

Future Trends in CNC Machining for the Aerospace Industry

The future of Computer Numerically Controlled (CNC) machining in the aerospace industry promises to introduce significant trends and developments that could revolutionize the sector. With advancements predicted in automation, accuracy and speed, companies are expected to increase efficiency and lower manufacturing costs significantly.

- Automation:One key development is increased automation through Artificial Intelligence (AI) and machine learning algorithms which will streamline the production process and reduce human errors.

- Accuracy:Another trend is improvements in precision and repeatability; next-gen CNC machines will likely be able to create highly complex components with utmost accuracy and without need for manual tuning or adjustments.

- Speed:Finally, enhancements in speed and material capabilities thanks to high-speed spindles and advanced tool materials will enable faster production times – making it possible to manufacture more intricate parts using difficult-to-machine materials common in aerospace applications.

All these potential advancements have broad implications on the wider aerospace industry including improved product quality, cost-optimisation, and shortened lead times. For instance, automated CNC machining processes can enhance production flow, enabling quicker delivery of aircrafts. Moreover, the possibility of cutting down on labour-intensive tasks doesn’t only mean reduced costs but also a safer workplace environment. Hence, these advancements in CNC machining truly hold potential to reshape the landscape of the aerospace industry.

Other Articles You Might Enjoy

- Precision Prowess: Unveiling the Advantages of China CNC Machining

1. Introduction: The Role of Precision in Manufacturing Excellence In this introductory section, we delve into the critical role that precision plays in manufacturing and set the stage for an…

- Elevating Industries through the Advantages of China CNC Machining

1. Introduction: Transformative Impact on Industries In this introductory section, we explore how China CNC machining has become a driving force in transforming various industries. We set the stage for…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…