Introduction

Bead blasting and CNC machining are integral processes in modern manufacturing, each playing a crucial role in producing high-quality components. When combined, they offer unparalleled precision, surface finish, and durability. This article delves into the intricacies of bead blasting and CNC machining, particularly focusing on bronze, a material renowned for its strength and aesthetic appeal.

Understanding Bead Blasting

Bead blasting is a surface finishing process that involves propelling fine beads at high velocity onto a material’s surface. The impact of these beads smooths out imperfections, cleans the surface, and imparts a uniform texture. The beads can be made of various materials such as glass, ceramic, or plastic, each offering different results.

Benefits of Bead Blasting

- Surface Uniformity: Bead blasting creates a consistent, uniform finish, essential for both aesthetic and functional purposes.

- Enhanced Aesthetic Appeal: It can produce matte or satin finishes, enhancing the visual quality of the components.

- Improved Cleanliness: The process removes oxides, scale, and other contaminants, ensuring a clean surface.

- Stress Relief: The impact induces compressive stress, reducing the risk of stress corrosion cracking.

- Versatility: Suitable for complex geometries and intricate designs.

CNC Machining: Precision and Versatility

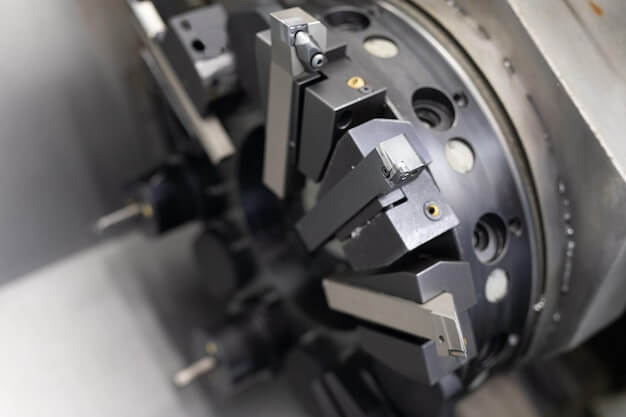

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process offers high precision, repeatability, and efficiency.

Advantages of CNC Machining

- High Precision: CNC machining ensures tight tolerances and high accuracy in part production.

- Consistency: The automated process reduces the likelihood of human error, providing consistent results.

- Complex Designs: Capable of producing complex shapes and intricate details that would be difficult with manual machining.

- Material Versatility: Works with a wide range of materials, including metals, plastics, and composites.

Bronze Machining: Challenges and Solutions

Bronze, an alloy primarily consisting of copper and tin, is prized for its durability, corrosion resistance, and aesthetic qualities. However, machining bronze poses certain challenges due to its properties.

Challenges in Bronze Machining

- Material Hardness: Bronze can be harder than many other materials, leading to tool wear.

- Heat Generation: Machining bronze generates significant heat, which can affect both the tool and the material.

- Chip Formation: Bronze tends to form long, stringy chips that can complicate the machining process.

Solutions for Effective Bronze Machining

- Tool Selection: Using tools with appropriate coatings and geometries to handle bronze’s hardness and heat generation.

- Coolant Use: Employing coolants to manage heat and prolong tool life.

- Optimized Parameters: Adjusting cutting speeds, feeds, and depths to minimize issues with chip formation and tool wear.

Combining Bead Blasting and CNC Machining for Bronze Components

When machining bronze components, combining CNC machining and bead blasting can result in superior products. CNC machining provides the necessary precision and intricate details, while bead blasting enhances the surface finish and aesthetic appeal.

Steps in the Combined Process

- CNC Machining: The bronze component is precisely machined to the desired specifications.

- Initial Cleaning: Any residual machining lubricants and debris are removed.

- Bead Blasting: The machined part undergoes bead blasting to achieve a uniform, clean, and aesthetically pleasing surface.

- Final Inspection: The finished component is inspected for quality assurance.

Applications of Bead Blasting and CNC Machining in Bronze

- Aerospace: High-precision bronze components used in aerospace applications benefit from the durability and finish provided by this combination.

- Marine: Bronze’s corrosion resistance makes it ideal for marine hardware, with bead blasting providing added protection and aesthetic quality.

- Architecture: Decorative bronze elements in architecture achieve enhanced visual appeal through bead blasting.

- Art and Sculpture: Artists use these techniques to create intricate, polished bronze sculptures and artworks.

Conclusion

The combination of bead blasting and CNC machining offers significant advantages for producing high-quality bronze components. By understanding and leveraging the strengths of both processes, manufacturers can achieve exceptional precision, surface finish, and durability in their products. This synergy opens up new possibilities for applications across various industries, from aerospace to art, where the superior qualities of bronze are highly valued.

Other Articles You Might Enjoy

- Corrosion Resistance in CNC Machining: Stainless Steel Alloys Compared

Introduction to CNC Machining and Corrosion Resistance CNC (Computer Numerical Control) machining stands as a pivotal manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery.…

- CNC Machining for the Renewable Energy Sector: Material Choices for Durability and Efficiency

Introduction to CNC Machining in the Renewable Energy Sector CNC (Computer Numerical Control) machining stands as a pivotal manufacturing process in the renewable energy sector, enabling the precise production of…

- High Volume CNC Machining in Copper: Efficiency at Scale

Introduction to High Volume CNC Machining in Copper CNC (Computer Numerical Control) machining is a subtractive manufacturing process involving pre-programmed computer software dictating the movement of factory tools and machinery.…

Afrikaans

Afrikaans Albanian

Albanian Amharic

Amharic Arabic

Arabic Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Chichewa

Chichewa Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Corsican

Corsican Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Esperanto

Esperanto Estonian

Estonian Filipino

Filipino Finnish

Finnish French

French Frisian

Frisian Galician

Galician Georgian

Georgian German

German Greek

Greek Gujarati

Gujarati Haitian Creole

Haitian Creole Hausa

Hausa Hawaiian

Hawaiian Hebrew

Hebrew Hindi

Hindi Hmong

Hmong Hungarian

Hungarian Icelandic

Icelandic Igbo

Igbo Indonesian

Indonesian Irish

Irish Italian

Italian Japanese

Japanese Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korean

Korean Kurdish (Kurmanji)

Kurdish (Kurmanji) Kyrgyz

Kyrgyz Lao

Lao Latin

Latin Latvian

Latvian Lithuanian

Lithuanian Luxembourgish

Luxembourgish Macedonian

Macedonian Malagasy

Malagasy Malay

Malay Malayalam

Malayalam Maltese

Maltese Maori

Maori Marathi

Marathi Mongolian

Mongolian Myanmar (Burmese)

Myanmar (Burmese) Nepali

Nepali Norwegian

Norwegian Pashto

Pashto Persian

Persian Polish

Polish Portuguese

Portuguese Punjabi

Punjabi Romanian

Romanian Russian

Russian Samoan

Samoan Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sesotho

Sesotho Shona

Shona Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Somali

Somali Spanish

Spanish Sundanese

Sundanese Swahili

Swahili Swedish

Swedish Tajik

Tajik Tamil

Tamil Telugu

Telugu Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Uzbek

Uzbek Vietnamese

Vietnamese Welsh

Welsh Xhosa

Xhosa Yiddish

Yiddish Yoruba

Yoruba Zulu

Zulu