Introduction to CNC Machining in the Renewable Energy Sector

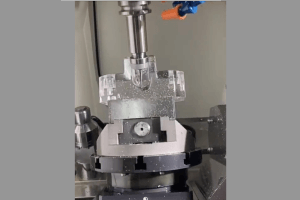

CNC (Computer Numerical Control) machining stands as a pivotal manufacturing process in the renewable energy sector, enabling the precise production of complex parts required for various technologies. This process involves the use of computerized controls and machine tools to remove layers of material from a stock piece, creating parts with high precision and accuracy. Its importance in the renewable energy sector cannot be overstated, as it allows for the efficient and durable construction of components critical to the functionality of renewable energy systems. For example, CNC machining is instrumental in producing turbine blades for wind energy, which require exact specifications for optimal performance and efficiency. By leveraging CNC machining, the renewable energy sector can achieve advancements in technology with components that meet stringent requirements for durability and efficiency.

Common Misunderstandings About Manufacturing in Renewable Energy

One prevalent misconception is that CNC machining and manufacturing are not pertinent to the renewable energy sector. This view overlooks the critical role of precision manufacturing in enhancing the efficiency and durability of renewable energy systems. For instance:

- Wind Turbines: Precision-engineered components, such as gears and blades, are essential for maximizing energy capture and conversion efficiency.

- Solar Panels: The frames and mounting systems require exact specifications to ensure optimal alignment and exposure to sunlight.

- Hydroelectric Systems: Turbine blades and generators must be manufactured to precise tolerances to prevent energy loss and ensure long-term reliability.

Thus, CNC machining plays a pivotal role in the renewable energy sector by ensuring components meet stringent specifications for performance and longevity.

Case Study: Wind Turbine Components

Wind turbine components demand durability and efficiency to withstand harsh environmental conditions and maximize energy production. CNC machining offers precise manufacturing of turbine parts, ensuring high performance and longevity. To explore material choices for wind turbine components, it’s advisable to consult experts in online CNC service for comprehensive insights.

Case Study: Wind Turbine Components

CNC machining plays a pivotal role in the production of wind turbine components, ensuring their durability and efficiency. A specific example is the machining of turbine blades and hubs, which are critical for the turbine’s operation. The material choice for these components is crucial:

- Turbine Blades: Often made from advanced composites or aluminum alloys, these materials are selected for their strength-to-weight ratio, enhancing the turbine’s efficiency by allowing for larger blades that capture more wind with less material weight.

- Hubs: Typically constructed from high-grade steel or aluminum, chosen for their durability and ability to withstand the high stress and fatigue experienced at the point where the blades meet the rotor.

These material choices significantly impact the turbine’s efficiency and lifespan by optimizing the balance between durability and performance. The precision of CNC machining ensures that these components meet exact specifications, reducing wear and tear and extending the operational life of the wind turbine.

Challenges in Material Selection for CNC Machining in Renewable Energy Applications

Choosing the right materials for CNC machining in the renewable energy sector involves navigating several challenges. These challenges primarily revolve around:

- Cost: High-performance materials that offer durability and efficiency often come with a higher price tag. Balancing cost without compromising on quality is crucial.

- Availability: Some materials ideal for renewable energy applications are scarce or have fluctuating availability, which can delay production schedules.

- Environmental Impact: The material’s lifecycle, including its production, usage, and disposal, must have a minimal environmental footprint to align with the renewable energy sector’s goals.

For example, selecting aluminum for its lightweight and corrosion resistance in wind turbine components must consider the energy-intensive production of aluminum and explore recycling options to mitigate environmental impact.

Innovations in Material Science for Renewable Energy

Recent advancements in material science significantly benefit CNC machining processes in the renewable energy sector. A notable development is the creation of new alloys tailored for enhanced performance under harsh environmental conditions. These materials are designed to withstand extreme temperatures, corrosion, and wear, making them ideal for components in wind turbines, solar panels, and hydroelectric power facilities. For instance:

- High-Temperature Alloys: Used in wind turbines, these alloys maintain structural integrity and resist oxidation at elevated temperatures.

- Corrosion-Resistant Alloys: Essential for offshore wind farms and hydroelectric plants, these materials prevent degradation from saltwater and moisture.

- Wear-Resistant Alloys: Applied in moving parts of renewable energy machinery, they extend the lifespan of components exposed to continuous friction.

These innovations ensure that machinery in the renewable energy sector operates more efficiently and with greater durability, directly contributing to the sustainability and cost-effectiveness of renewable energy sources.

Other Articles You Might Enjoy

- High Volume CNC Machining in Copper: Efficiency at Scale

Introduction to High Volume CNC Machining in Copper CNC (Computer Numerical Control) machining is a subtractive manufacturing process involving pre-programmed computer software dictating the movement of factory tools and machinery.…

- Understanding Bead Blasting in CNC Machining(cnc g code Jacqueline)

CNC (Computer Numerical Control) machining is a dominant method employed for multiple manufacturing systems across the globe. From healthcare to aerospace, this technology has revolutionized how we manufacture products. One…

- Exploring Bead Blasting in CNC Machining(chamfer Yvette)

Bead blasting is an essential surface finishing process used extensively in industries, such as the aerospace, automotive and manufacturing sectors. As part of CNC (Computer Numerical Control) machining, this technique…

Afrikaans

Afrikaans Albanian

Albanian Amharic

Amharic Arabic

Arabic Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Chichewa

Chichewa Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Corsican

Corsican Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Esperanto

Esperanto Estonian

Estonian Filipino

Filipino Finnish

Finnish French

French Frisian

Frisian Galician

Galician Georgian

Georgian German

German Greek

Greek Gujarati

Gujarati Haitian Creole

Haitian Creole Hausa

Hausa Hawaiian

Hawaiian Hebrew

Hebrew Hindi

Hindi Hmong

Hmong Hungarian

Hungarian Icelandic

Icelandic Igbo

Igbo Indonesian

Indonesian Irish

Irish Italian

Italian Japanese

Japanese Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korean

Korean Kurdish (Kurmanji)

Kurdish (Kurmanji) Kyrgyz

Kyrgyz Lao

Lao Latin

Latin Latvian

Latvian Lithuanian

Lithuanian Luxembourgish

Luxembourgish Macedonian

Macedonian Malagasy

Malagasy Malay

Malay Malayalam

Malayalam Maltese

Maltese Maori

Maori Marathi

Marathi Mongolian

Mongolian Myanmar (Burmese)

Myanmar (Burmese) Nepali

Nepali Norwegian

Norwegian Pashto

Pashto Persian

Persian Polish

Polish Portuguese

Portuguese Punjabi

Punjabi Romanian

Romanian Russian

Russian Samoan

Samoan Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sesotho

Sesotho Shona

Shona Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Somali

Somali Spanish

Spanish Sundanese

Sundanese Swahili

Swahili Swedish

Swedish Tajik

Tajik Tamil

Tamil Telugu

Telugu Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Uzbek

Uzbek Vietnamese

Vietnamese Welsh

Welsh Xhosa

Xhosa Yiddish

Yiddish Yoruba

Yoruba Zulu

Zulu