In the complex landscape of CNC machining, finishing techniques play a crucial role in defining the final attributes of the manufactured parts. Among these, abrasive finishing stands out for its ability to impart desired surface qualities efficiently. This article offers an in-depth exploration of bead blasting vis-a-vis other abrasive methods, aiming to guide practitioners in making informed choices.

Understanding Abrasive Finishing in CNC Machining

Abrasive finishing processes in CNC machining utilize various abrasive materials to achieve desired surface characteristics on manufactured parts. From traditional sandblasting to sophisticated bead blasting, each method offers unique advantages and is suitable for specific applications. The selection of an abrasive finishing technique significantly impacts the final product’s quality, influencing factors like surface roughness, dimensional accuracy, and aesthetics.

Bead Blasting: An Overview

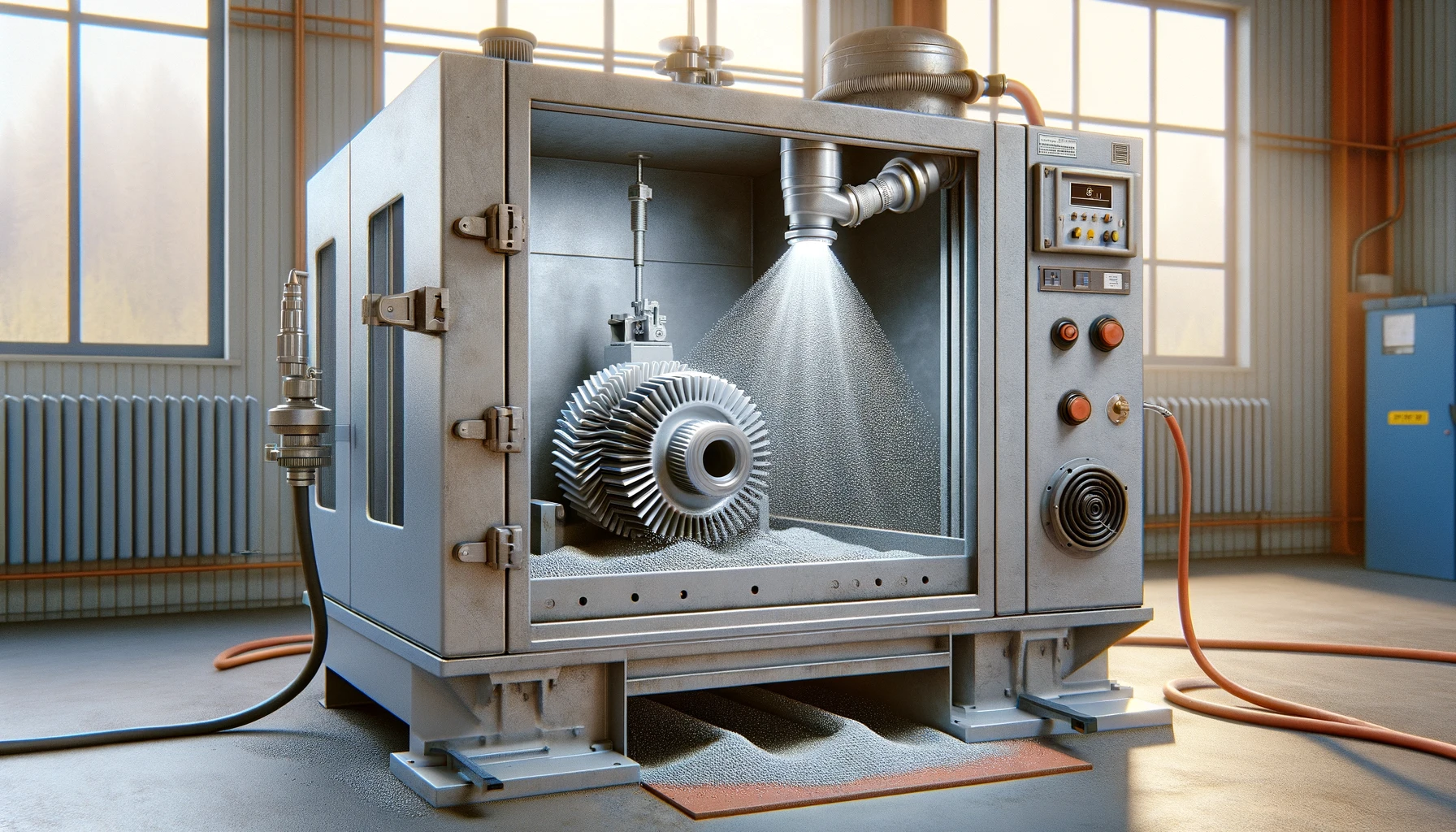

Bead blasting is a finishing technique where small, spherical beads are propelled at high velocity towards the workpiece’s surface. This method is known for delivering a uniform, smooth finish without introducing thermal stress or altering the dimensional integrity of the workpiece.

Comparative Analysis of Abrasive Techniques

In comparing bead blasting with other abrasive finishing methods such as sandblasting, water jet cutting, and laser engraving, it’s essential to consider several key factors: the finish quality, processing speed, equipment and operational costs, and the environmental impact.

Bead blasting often emerges as the preferred choice for applications requiring a delicate balance between surface smoothness and material integrity. Unlike sandblasting, which can be overly aggressive for softer materials, bead blasting offers a gentler alternative that minimizes the risk of substrate damage. Water jet cutting, while precise, tends to be slower and more costly, making it less ideal for large-scale or budget-sensitive projects. Laser engraving offers unmatched precision but at a higher operational cost and limited material compatibility.

Comparative Table: Abrasive Techniques

The expanded table below provides a detailed comparison across a broader spectrum of abrasive techniques, including newer, less conventional methods such as ultrasonic machining and electrochemical finishing, to offer a comprehensive overview of the available options.

| Technique | Surface Roughness (Ra) | Processing Speed | Cost Efficiency | Environmental Impact | Material Compatibility |

|---|---|---|---|---|---|

| Bead Blasting | 0.2 – 0.8 µm | High | High | Low | Wide Range |

| Sandblasting | 0.5 – 1.5 µm | Medium | Medium | Medium | Metals, Hard Plastics |

| Water Jet Cutting | 0.1 – 0.7 µm | Low | Low | Medium | Almost All |

| Laser Engraving | 0.05 – 0.5 µm | Low | High | High | Metals, Ceramics |

| Ultrasonic Machining | 0.1 – 0.6 µm | Medium | Medium | Low | Brittle Materials |

| Electrochemical Finishing | 0.05 – 0.4 µm | High | High | Low | Conductive Materials |

| Plasma Finishing | 0.2 – 1.0 µm | High | Medium | Medium | Metals, Some Plastics |

| Chemical Milling | 0.2 – 1.2 µm | Medium | Low | High | Metals, Some Plastics |

Material Compatibility and Selection for Abrasive Processes

Choosing the right abrasive process hinges on understanding the material properties of the workpiece. Bead blasting shines in its adaptability, catering to a broad spectrum of materials including metals, plastics, glass, and ceramics. This versatility makes it an ideal choice for a wide range of applications, from automotive parts to delicate electronic components.

Materials with higher hardness levels, such as steel and titanium, can withstand more aggressive abrasive techniques like sandblasting, whereas softer materials like aluminum and plastic may fare better with bead blasting, which is less likely to cause surface damage or deformation. Similarly, the thermal sensitivity of certain polymers and composites requires a low-impact finishing technique to prevent warping or other heat-induced damage.

The selection process also involves considering the desired finish. For instance, bead blasting can achieve a smooth, matte finish that’s often sought after for aesthetic or paint-preparation purposes, while other techniques might be better suited for creating specific textures or preparing a surface for bonding.

Case Studies: Material-Specific Applications

- Automotive Industry: Bead blasting was employed to finish aluminum alloy wheels, achieving a uniform surface ideal for the subsequent coating, which enhanced both durability and visual appeal.

- Aerospace Sector: Titanium turbine blades underwent bead blasting to improve their fatigue resistance and surface finish, crucial for optimal aerodynamic performance.

- Electronics Manufacturing: Bead blasting was used to delicately finish PCBs, ensuring a clean surface without damaging the sensitive electronic components.

Strategies for Cost-Effective Bead Blasting

Achieving cost-effectiveness in bead blasting involves optimizing various facets of the process, from media selection to equipment maintenance and process parameters. Media type and size play a crucial role in both the finish quality and the rate of media consumption. Using recyclable media, such as certain types of glass beads, can significantly reduce costs associated with media replenishment.

Investing in advanced bead blasting equipment can offer higher efficiency and lower long-term costs. Features like precise media flow controls, efficient dust collection systems, and durable blasting cabinets can minimize waste and extend equipment lifespan, contributing to a more sustainable and cost-effective operation.

Process optimization is another key strategy. By fine-tuning parameters such as blasting pressure, angle, and distance, operators can achieve the desired finish more quickly and with less media, further reducing costs. Implementing a regular maintenance schedule for blasting equipment ensures consistent performance and prevents costly downtime.

Case Studies: Cost Reduction through Optimization

- Industrial Machinery: A manufacturer of heavy machinery integrated an automated bead blasting system, which led to a 50% decrease in processing time and a 30% reduction in media consumption.

- Marine Industry: Shipyard maintenance operations adopted bead blasting with recycled glass media for hull cleaning, significantly cutting down on waste and reducing overall maintenance costs.

- Architectural Metalwork: A fabricator of architectural metal components utilized bead blasting for surface finishing, employing a closed-loop system that recycled the blast media, resulting in substantial savings on media costs.

Case Study: Industrial Valve Refurbishment

An industrial valve manufacturer integrated a state-of-the-art bead blasting system into their refurbishment line. The system’s advanced media recovery and recycling capabilities resulted in a 50% reduction in media consumption and a 35% decrease in processing time for valve surface preparation, highlighting the potential for significant cost savings and efficiency improvements in industrial applications.

Innovations and Technological Advances in Bead Blasting

The bead blasting landscape is continually evolving, spurred by technological advancements that aim to increase efficiency, reduce costs, and lessen environmental impact. New materials for beads, such as engineered ceramics and environmentally friendly composites, are being developed to offer longer life spans and less environmental burden. Equipment advancements are also notable, with features that enhance precision and user control.

Table: Innovations in Bead Blasting Technology

The table below outlines some of the notable innovations in bead blasting technology, emphasizing the benefits that each brings to the process:

| Innovation | Description | Impact on Efficiency | Cost Reduction | Environmental Benefit |

|---|---|---|---|---|

| Recyclable Bead Media | Beads that can be used for multiple cycles without loss of integrity | Increases operational efficiency by reducing media replacement frequency | Reduction in media costs over time | Decrease in waste produced, beneficial for environmental sustainability |

| Advanced Nozzle Designs | Nozzles that provide more focused blasting and reduced media use | Precision in blasting improves efficiency and quality of finish | Less media used results in cost savings | Less dust and waste produced, improving environmental safety |

| Automated Blasting Systems | Systems that automate the blasting process, including media delivery and recovery | Automation ensures consistent results and optimizes blasting times | Labor cost savings and improved long-term ROI | Improved resource utilization contributes to environmental efficiency |

| High-Efficiency Dust Collectors | Dust collection systems that capture fine particles more effectively | Clean working environment and better visibility during blasting | Reduction in cleaning and maintenance costs | Better air quality and reduced particulate emissions |

| Eco-Friendly Blasting Media | Beads made from sustainable materials | Effective blasting with a lower ecological footprint | Comparable costs to traditional media | Significantly reduced environmental impact |

| Pressure Control Systems | Precise control over blasting pressure for various applications | Allows customization of blasting to the task, potentially reducing time | Fine-tuning reduces unnecessary media use | Precise application reduces over-blasting and waste |

| Digital Monitoring Systems | Sensors and software for real-time monitoring of the blasting process | Improved process oversight can prevent mistakes and enhance efficiency | Prevention of overuse and waste reduces costs | Optimization of blasting parameters can reduce environmental impact |

| On-Demand Bead Blasting | On-site bead blasting services that reduce the need for investment in equipment | Companies can pay for services as needed without capital expenditure | Savings on equipment purchase and maintenance | Service providers often use the most up-to-date, efficient, and eco-friendly options |

These advancements represent just a portion of the ongoing development in bead blasting technology. As industries push for higher precision and environmental stewardship, the bead blasting field responds with innovations that align with these values. Manufacturers benefit from these technological advancements through improved finishing processes, cost savings, and a commitment to sustainability.

In conclusion, selecting the right abrasive technique for a CNC machining project involves a multifaceted approach. Understanding the material properties, desired outcomes, and the implications of cost and environmental impact will guide manufacturers toward making informed decisions. Innovations in bead blasting technology continue to expand the possibilities of abrasive finishing, offering new ways to enhance efficiency, reduce costs, and minimize the environmental footprint. By staying informed of these advancements and carefully considering their practical applications, practitioners in CNC machining can optimize their processes to achieve superior results.

Selecting the Right Abrasive Technique for Your Project

The culmination of understanding various abrasive techniques, their material compatibilities, and strategies for cost-effective implementation leads to the crucial decision-making process: selecting the right abrasive technique for your specific project. This decision is influenced by a myriad of factors, each interplaying to dictate the most suitable method for achieving the desired outcome while maintaining efficiency and cost-effectiveness.

- Assess Material Properties: Begin by thoroughly evaluating the material properties of the workpieces involved. Consider aspects such as hardness, brittleness, and thermal sensitivity, which will significantly influence the choice of abrasive technique. For delicate or heat-sensitive materials, gentler methods like bead blasting may be preferable to prevent damage.

- Define Desired Finish: Clearly articulate the finish requirements for your project. Are you aiming for a smooth, matte finish, a specific texture, or preparing the surface for subsequent treatments like painting or coating? Different abrasive techniques offer varying finish characteristics, so aligning your finish goals with the capabilities of each method is paramount.

- Consider Environmental Impact: In today’s environmentally conscious manufacturing landscape, the ecological footprint of your chosen abrasive technique is a critical consideration. Techniques that use recyclable media or produce less waste and pollution are increasingly favored. Assess the environmental implications of each method and strive for sustainable practices.

- Evaluate Cost Implications: Analyze the cost-effectiveness of each abrasive technique, considering not only the upfront costs but also long-term expenses related to media consumption, equipment maintenance, and operational efficiency. Opt for a method that offers a balance between achieving the desired finish and maintaining economic viability.

- Leverage Technological Innovations: Stay informed about the latest advancements in abrasive technologies. Innovations in media, equipment, and process automation can offer new opportunities for efficiency gains and cost savings. Evaluate how these advancements can be integrated into your project to enhance outcomes.

- Consult with Experts: When in doubt, consult with industry experts or abrasive technique specialists. Their insights and experience can provide valuable guidance, helping you navigate the complexities of abrasive finishing and select the most appropriate method for your project.

- Test and Iterate: Finally, consider conducting preliminary tests with your shortlisted abrasive techniques on sample workpieces. Real-world testing can reveal practical insights that theoretical analysis may overlook, allowing you to fine-tune your approach before full-scale implementation.

Conclusion

Selecting the right abrasive technique is a multifaceted decision that impacts the quality, efficiency, and cost-effectiveness of your CNC machining projects. By carefully considering material properties, desired finishes, environmental impacts, cost implications, and staying abreast of technological advancements, you can make informed choices that enhance the value and sustainability of your manufacturing processes. Remember, the optimal choice is not solely about the technique itself but how well it aligns with the specific requirements and constraints of your project.

Other Articles You Might Enjoy

- Innovative CNC Machining for Complex Surgical Tools

Introduction to CNC Machining and its Significance in Surgical Tools Manufacturing CNC machining, an acronym for Computer Numerical Control machining, plays a significant role in the manufacturing world. Being an…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…