CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry. It provides high levels of accuracy, reduces production time, and has the ability to reproduce intricate designs flawlessly. One aspect integral part to many CNC processes is bead blasting.

Bead blasting is a type of surface finishing commonly used in conjunction with CNC machining. More specifically, it’s a mechanical process that uses compressed air or centrifugal force to project small beads at the surface of a component. Irrespective of whether you’re using stainless steel, aluminum, brass, or any other material often processed through CNC machining, bead blasting has its place.

So why use bead blasting in CNC machining? This unique procedure enhances the surface finish of machined parts, cleans them thoroughly, and prepares them for further processing – coating, painting, anodizing etc. Precisely, it is advantageous because of its versatility in treating different materials and configurations, consistency in achieving desired finishes, non-disruptive action on the base material, and ability to improve fatigue strength of machined components.

Producing an item by incorporating bead blasting with CNC machining involves multiple steps unfold. Let’s unravel this complexity:

Step 1: Designing

The first step is drafting a CAD (Computer-Aided Design) model of the product. For accurate and optimized CNC machining, the design must include details about dimensions, tolerances, and surface finish requirements.

Step 2: Programming

Next, programmers or engineers translate the CAD model into a CNC program or G-code. This coding dictates the operation of the CNC machine during fabrication.

Step 3: Material Procurement

Before initiating the actual machining, it’s necessary to have the correct material based on the specific application’s need. Selecting the right raw material ensures durability and performance of the final product.

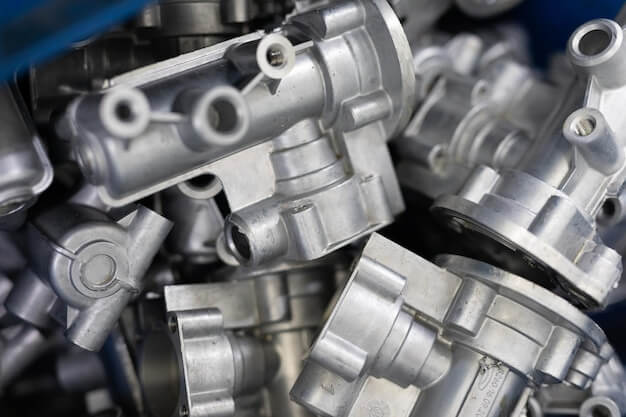

Step 4: CNC Machining

Now, the defined material block is subjected to various machining processes like milling, drilling or turning on a CNC machine. Here, the part gradually takes its pre-defined shape under programmed control.

Step 5: Bead Blasting

After machining, bead blasting comes into play. A high-pressure system projects tiny glass beads at the surface of the machined part, removing microscopic burrs and creating a uniform, matte-like finish. It also helps in contaminant removal for better adhesion during subsequent plating or painting.

Step 6: Inspection & Finishing

Finally, after bead blasting, quality assurance checks take place. The component is inspected for dimensional accuracy and required surface finish. Depending upon further requirements, additional finishing procedures may follow.

Bead blasting in tandem with CNC machining delivers impeccable products that display aesthetic appeal alongside structural superiority. While it might be an added process, the benefits it brings to table unequivocally outweighs any concerns about increased workload or cost. Indeed, industries ranging from automotive to aerospace, healthcare to energy sectors are increasingly embracing this technique to meet their exacting standards.

A competent CNC machining service provider with expertise in bead blasting can help you successfully deliver complex projects with stringent specifications. Their vast knowledge make sure your parts are produced precisely as they were designed to be.

In conclusion, bead blasting enhances the overall quality of CNC machined components ensuring longevity, aesthetics and functionality remain uncompromised. Despite being so vital, it often tends to be overlooked during manufacturing planning stage. Therefore, next time when dealing with CNC machining, don’t forget about the hidden champion – bead blasting!

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Breaking Barriers in CNC Machined Aerospace Structures

Introduction: CNC Machining in Aerospace Structures In the aerospace industry, accuracy, reliability and efficiency are paramount. To maintain these standards, modern day aerospace manufacturing heavily leans on Computer Numerical Control…