Crafting Custom Jewelry with Precision CNC Machining in Precious Metals

Custom jewelry entails unique, handcrafted pieces tailored to a client’s specific tastes and preferences. In this realm of bespoke design, it cannot be stressed enough that precision and quality are key determinants to achieving exceptional results. Precise machining ensures the perfect realization of complex designs while high-quality metals ensure longevity and a premium finish of the final product. Errors in sizes, measurements or alignments have no room here as they can profoundly affect the jewelry’s aesthetics and functionality.

- Precision: With custom pieces, every millimeter matters; hence precise cutting using Computer Numerical Control (CNC) machines becomes crucial

- Quality: The choice of metal greatly impacts the overall piece, so opting for precious metals like gold, silver or platinum is integral to enhancing its luxurious appeal and durability.

Precision CNC Machining in Jewelry Crafting

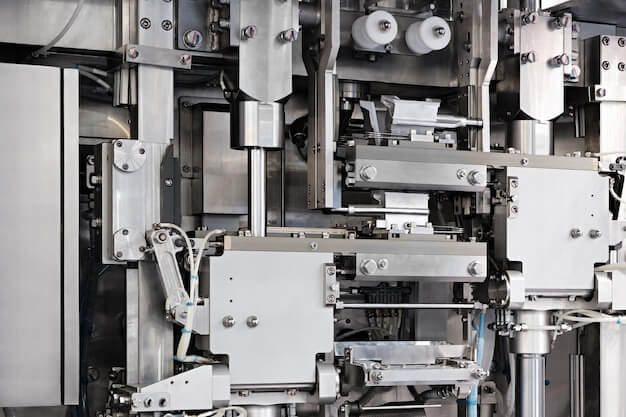

Precision Computer Numerical Control (CNC) machining is a technology that utilizes computer-generated code to instruct machinery on how to perform various tasks with high precision. This advanced method translates digital designs into physical objects by controlling the movement and operation of tools such as millers or lathes.

This tool-centered control system is pivotal in crafts like custom jewelry production due to its capability for meticulous detail, accuracy, and consistency that facilitates complex geometries without compromising quality. For instance:

- The technology allows jewelers to fine-tune intricate parts like clasps or setting tiny stones accurately, ensuring they fit perfectly and securely.

- Its precision eliminates errors common in manual work, such as asymmetry in identical pieces of earrings or rings.

- CNC machines can replicate designs flawlessly, which ensures each produced piece matches the original design,

In conclusion, Precision CNC machining offers invaluable benefits in crafting elaborate personal adornments, shaping the future of jewelry manufacturing.

Applications of Precision CNC Machining in Jewelry Making:

- CNC machining can be used to produce master models, molds, and engravings for jewelry production.

- It is cost-effective for producing flat jewelry prototypes and conducive to large-volume production.

- CNC machining offers engraving capability, high precision, and the ability to impart various finishes on metal jewelry items.

- It also allows for post-processing solutions that guarantee aesthetic and high-quality surface finishes.

Advantages of Using Precision CNC Machining in Crafting Custom Jewelry

Precision CNC machining has several distinct advantages over traditional manual methods for crafting custom jewelry. Firstly, CNC machining is renowned for its accuracy and consistency. Because the process is automated and computer-guided, this method can achieve much finer details than human handwork alone could match reliably across multiple pieces. CNC tools work with high precision that ensures perfect replication – a factor critical especially when creating identical pieces in a collection.

-

The second major advantage is its time-saving nature. Since it’s an automated procedure, it drastically reduces production time. Handcrafting each piece individually may enhance value through gleaned exclusiveness but also requires significant labor and time investment which translates to higher costs. The rapid, around-the-clock operation of CNC machinery bypasses these issues completely without compromising on quality or design integrity.

-

Lastly, the increased efficiency achieved by using CNC machining correlates directly to cost-efficiency. Even though the initial setup cost of CNC equipment might be higher compared to manual methods, the return on investment eventually outweighs due to the machine’s speed, precision, versatility, reduced waste material, and minimal errors. This makes it worthwhile especially for large-scale productions.

In comparing this methodology with traditional jewelry-making techniques, it becomes apparent that while both have their merits, the use of modern technology via precision CNC machining provides a considerable advantage in terms of accuracy consistency, better turnaround times, and cost optimization.

Crafting Custom Jewelry in Precious Metals

Precious metals hold a key role when it comes to producing exquisite jewelry pieces. Traditional favorites like gold, silver, and platinum are often utilized due to their lasting appeal, durability, and ability to complement gemstones with elegance. These hard materials are deftly crafted into intricate designs by precision CNC machines that offer unmatched accuracy even for the most complicated patterns.

- Gold is renowned for its rich color and easy malleability, making it ideal for crafting diverse shapes and styles.

- Silver is another widely used precious metal; aside from being affordable, it’s flexible and robust, which allows for more intricate designs.

- Platinum, known for its resistance to tarnishing and exceptional heft, emits a cool white sheen that offers timeless classiness.

Precision CNC machining transforms these valuable metals into custom jewelry items by utilizing computer-driven machinery capable of creating precise, repeatable cuts. This technology paves the way for realizing complex geometries and delicate features, thereby enabling designers to bring their creative visions to life with an extraordinary level of detail.

The Importance of Precision in Fine Jewelry Creation

In fine jewelry creation, precision plays a paramount role. An ensemble’s allure and quality are to a large degree determined by the meticulous attention given to their components’ shaping, assembling, and finishing. Every fraction of a millimeter matters when crafting custom pieces with precious metals, thereby necessitating precision far beyond human capability. Ensuring such precision is where CNC (Computer Numerical Control) machining steps in. This innovative system offers exceptional control over cutting tools, enabling precise duplication of intricate patterns, resulting in superior aesthetics and structural integrity.

- Interlinking Pieces: In designs that feature interlinking pieces, precision in sizing contributes significantly to a smooth assembly process, preventing potential breakages or loose fits.

- Gems Settings: Potential loss of precious gems due to poorly fitted settings is mitigated via precision machining. CNC machining assures specific dimensions for seating gemstones securely.

- Polish & Finish: The final polish and finish also benefit from precision processes, promising unmatched shine and durability without causing material wastage or deformation.

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Pioneering CNC Machining Solutions for the Electronics Industry

Introduction to CNC Machining in the Electronics Industry The use of Computer Numerical Control (CNC) machining, a system where computers execute control over machine tools, has become increasingly relevant and…