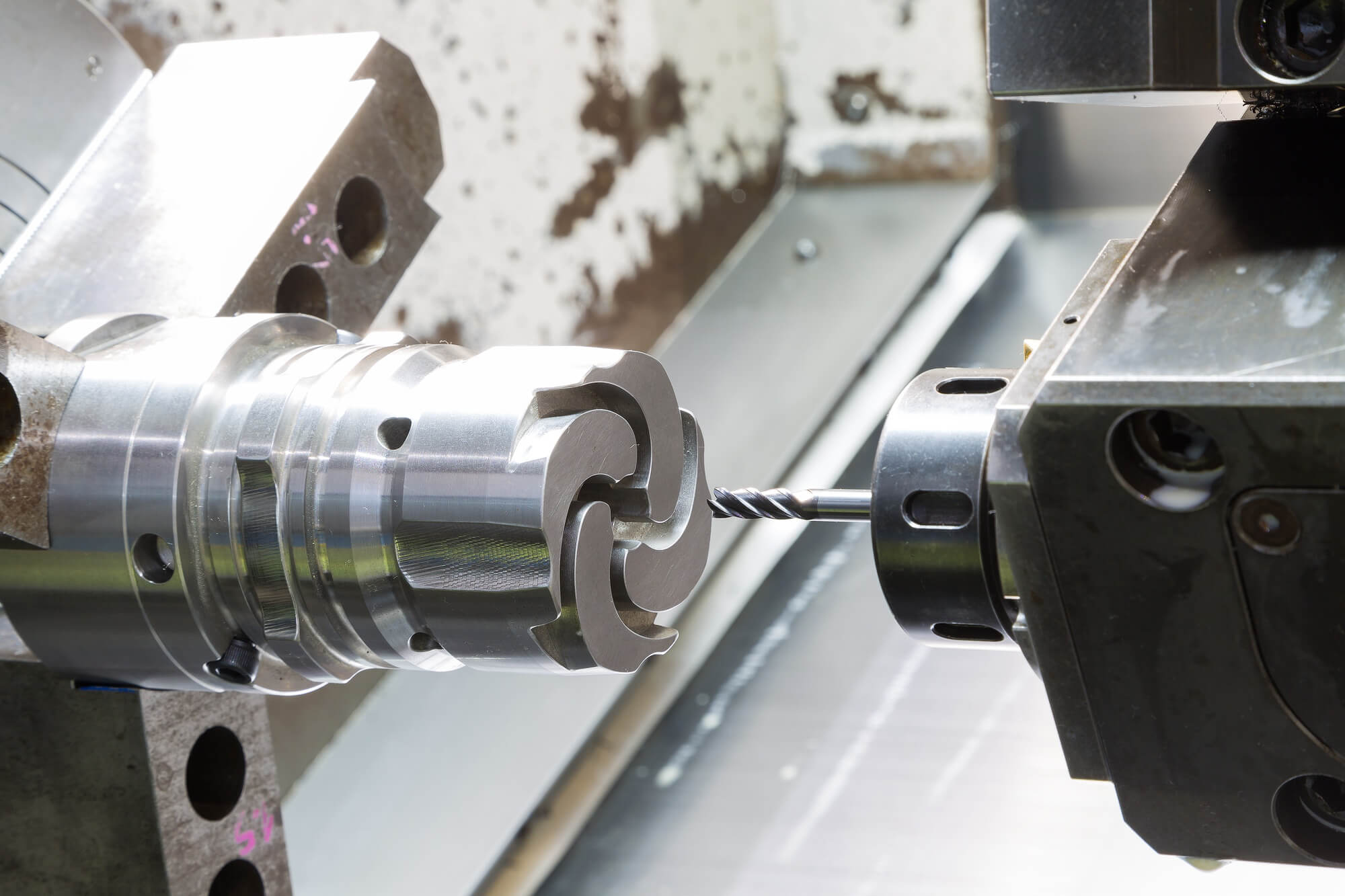

When it comes to CNC machining, understanding the mechanics of cutting is crucial. Various factors influence the cutting process, impacting everything from the quality of the finished part to the lifespan of the cutting tool. Let’s dive into these factors and see how they play a role in CNC machining.

Key Cutting Variables

Several independent variables impact the cutting process in CNC machining:

- Tool Material and Coating: The type of material and coating used on the cutting tool can significantly affect performance. Different materials have varying degrees of hardness, wear resistance, and heat tolerance.

- Tool Geometry: This includes the shape, surface roughness, and sharpness of the tool. Proper tool geometry ensures effective cutting and longer tool life.

- Workpiece Material: The material being machined plays a big role. Different materials respond differently to cutting, affecting tool wear and surface finish.

- Cutting Speed, Feed Rate, and Depth of Cut: These parameters need to be optimized for efficient cutting. They influence the cutting force, power consumption, and thermal effects.

- Cutting Fluids: These are used to cool and lubricate the cutting process, reducing tool wear and improving surface finish.

- Machine Tool Characteristics: The rigidity, power, and precision of the machine tool can impact the cutting process.

- Workholding: How the workpiece is clamped affects stability and vibration during cutting.

Dependent Variables in Cutting

The cutting process also involves dependent variables, which are outcomes influenced by the independent variables:

- Chip Formation: The shape and size of the chips formed during cutting.

- Cutting Forces and Energy Consumption: The forces exerted on the tool and the energy required for cutting.

- Temperature Rise: The heat generated in the workpiece, tool, and chips.

- Tool Wear and Failure: The rate at which the tool wears out and the mechanisms of tool failure.

- Surface Quality and Integrity: The finish and mechanical properties of the machined surface.

Chip Formation and Shear Mechanics

Understanding chip formation is fundamental to grasping cutting mechanics. The process involves shearing material off the workpiece, which forms chips. There are different types of chips, each indicating specific cutting conditions:

- Continuous Chips: These form under stable cutting conditions with good surface finish.

- Built-Up Edge Chips: Occur when material sticks to the cutting edge, affecting surface quality.

- Discontinuous Chips: Formed in brittle materials, often leading to rough surfaces.

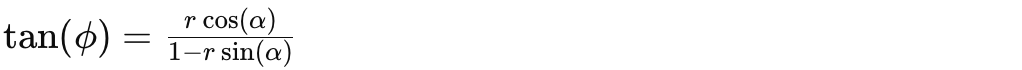

Shear Angle and Its Importance

The shear angle is a critical parameter in cutting mechanics. It affects the cutting force, power consumption, and temperature rise. The shear angle adjusts itself to minimize cutting forces, leading to efficient cutting. Factors like tool rake angle and friction between the tool and chip influence the shear angle.

The shear angle ((\phi)) can be calculated using the following relationship:

where:

- ( r ) is the cutting ratio (r = t_1/t_2),

- ( t_1 ) is the uncut chip thickness,

- ( t_2 ) is the chip thickness after cutting,

- ( alpha ) is the rake angle.

Influence of Cutting Speed, Feed Rate, and Depth of Cut

These parameters are vital for optimizing the cutting process:

- Cutting Speed: Higher speeds reduce cutting forces but increase temperature. There’s an optimal range for different materials.

- Feed Rate: It impacts chip load and cutting force. Too high a feed rate can lead to poor surface finish and tool breakage.

- Depth of Cut: This affects material removal rate. Higher depths of cut require more power and can lead to greater tool wear.

Practical Tips for CNC Machining

To achieve the best results in CNC machining, consider these practical tips:

- Choose the Right Tool: Match the tool material and geometry to the workpiece material and cutting conditions.

- Optimize Cutting Parameters: Use the recommended cutting speed, feed rate, and depth of cut for the material being machined.

- Use Cutting Fluids: Apply appropriate cutting fluids to reduce heat and improve surface finish.

- Ensure Rigidity: Secure the workpiece properly and ensure the machine tool is rigid to minimize vibrations.

- Monitor Tool Wear: Regularly check for tool wear and replace tools as needed to maintain quality and efficiency.

Detailed Examples and Calculations

To better understand how these variables interact, let’s look at some specific examples and calculations.

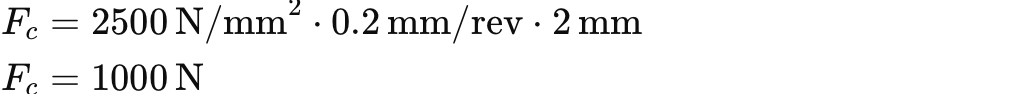

Example 1: Calculating Cutting Forces

Consider a turning operation with the following parameters:

- Cutting speed ((v_c)) = 200 m/min

- Feed rate ((f)) = 0.2 mm/rev

- Depth of cut ((d)) = 2 mm

- Workpiece material: Steel (with a specific cutting force (K_c) of 2500 N/mm²)

The main cutting force ((F_c)) can be estimated using the formula:

Plugging in the values:

Example 2: Optimizing Cutting Speed and Feed Rate

For a given material and tool, the recommended cutting speed and feed rate are crucial for achieving optimal results. The table below provides recommended values for different materials:

| Material | Cutting Speed (m/min) | Feed Rate (mm/rev) |

|---|---|---|

| Aluminum | 250 – 500 | 0.2 – 0.5 |

| Mild Steel | 150 – 300 | 0.1 – 0.3 |

| Stainless Steel | 100 – 200 | 0.05 – 0.2 |

| Cast Iron | 50 – 150 | 0.1 – 0.3 |

Conclusion

In CNC machining, understanding the influence of various cutting factors is essential for optimizing the process and achieving high-quality results. By considering the independent and dependent variables, and using practical tips, you can improve the efficiency and effectiveness of your CNC machining operations.

Other Articles You Might Enjoy

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Beyond Cutting: Exploring the Multifaceted CNC Machining Process

1. Introduction: Unveiling the Layers of CNC Machining In this introductory section, we peel back the layers of the CNC machining process, going beyond the traditional understanding of cutting. It…

- Exploring Bead Blasting In CNC Machining(cnc cutting tools Hale)

Bead blasting is a crucial technique applied extensively in the realm of Computer Numerical Control (CNC) machining. This process transforms the exterior aesthetics and surface quality of machined parts, augmenting…

- Comparing Machinability of Various Tool Steels: What's the Best Choice?

Understanding Tool Steels and their Machinability Tool steels are referred to as an extensive variety of carbon and alloy steels known for their distinctive hardness, abrasion resistance, and ability to…

- Understanding Bead Blasting in CNC Machining(cnc cutting tools Miles)

CNC machining is a manufacturing process known for its precision and versatility. One important aspect of this process that contributes significantly to both its functionality and finish quality is bead…

- The Future of Medical Device Manufacturing: CNC Machined Stainless Steel

Introduction to Medical Device Manufacturing Medical device manufacturing is a crucial sector in the healthcare industry, powering a myriad of medical procedures and treatments worldwide. This field involves the design,…