When it comes to CNC machining, threading is one of those tasks where precision is paramount. Most of the time, the G76 threading cycle is the go-to for machinists, handling about 95% of all threading jobs effortlessly. But what about that remaining 5%? What if the G76 cycle isn’t available or suitable for the task at hand? This is where manual calculations for each tool position and movement become essential.

Manual threading might sound tedious, but it’s a skill worth mastering. Here’s why: small adjustments made on the machine can be challenging and time-consuming. Investing time and effort upfront ensures that the final workpiece is of the highest quality and precision. Let’s dive into the nitty-gritty of G32 programming and manual threading, using a practical example to illustrate the process.

Understanding G32 Programming and Manual Threading

Imagine you’re tasked with threading a 3.0-12 TPI external thread. Here’s how you’d approach this manually, particularly when G76 isn’t an option.

Step 1: Determine the Depth for Each Pass

For this example, we need to calculate the depth for each threading pass. Here are the depths for six passes:

- First Pass: 0.0210 units per side

- Second Pass: 0.0087 units per side

- Third Pass: 0.0067 units per side

- Fourth Pass: 0.0056 units per side

- Fifth Pass: 0.0050 units per side

- Sixth Pass: 0.0040 units per side

These depths ensure a gradual and controlled cut, reducing the risk of tool wear or damage to the workpiece.

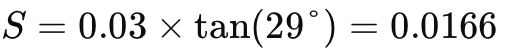

Step 2: Calculate the Total Offset (S)

Next, we need to calculate the total offset (S) for our threading passes. Given a compound infeed angle of 29° and a total thread depth of 0.03 units, we use the tangent function:

This value represents the total displacement of the tool from its initial position.

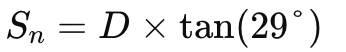

Step 3: Calculate the Offset for Each Pass

Using the formula:

Where D is the single-pass depth, we calculate the offsets for each pass:

- S1: 0.0087 × tan(29°) = 0.0048

- S2: 0.0067 × tan(29°) = 0.0037

- S3: 0.0056 × tan(29°) = 0.0031

- S4: 0.0050 × tan(29°) = 0.0028

- S5: 0.0040 × tan(29°) = 0.0022

Step 4: Determine Z-Axis Starting Positions

With the initial starting position at Z0.25, we calculate the new starting positions for each pass:

- First Pass: Z0.2500 + 0 = Z0.25

- Second Pass: Z0.2500 + 0.0048 = Z0.2548

- Third Pass: Z0.2548 + 0.0037 = Z0.2585

- Fourth Pass: Z0.2585 + 0.0031 = Z0.2616

- Fifth Pass: Z0.2616 + 0.0028 = Z0.2644

- Sixth Pass: Z0.2644 + 0.0022 = Z0.2666

These positions ensure that the tool is correctly offset for each pass, maintaining precision and avoiding collisions or incorrect cuts.

Practical Example: G32 Threading Program

Here’s an example of a G32 threading program based on the calculations above:

03805 (G32 Threading, Compound Infeed)

N59 T0500 M42

N60 G97 S450 M03

N61 G00 X3.3 Z0.25 T0505 M08

N62 X2.958 (Start position, first pass)

N63 G32 Z-1.6 F0.0833

N64 G00 X3.3

N65 Z0.2548

N66 X2.9406 (Offset S1, second pass)

N67 G32 Z-1.6

N68 G00 X3.3

N69 Z0.2585

N70 X2.9272 (Offset S2, third pass)

N71 G32 Z-1.6

N72 G00 X3.3

N73 Z0.2616

N74 X2.9160 (Offset S3, fourth pass)

N75 G32 Z-1.6

N76 G00 X3.3

N77 Z0.2644

N78 X2.9060 (Offset S4, fifth pass)

N79 G32 Z-1.6

N80 G00 X3.3

N81 Z0.2666

N82 X2.8980 (Offset S5, sixth pass)

N83 G32 Z-1.6

N84 G00 X3.3

N85 Z0.25 M09

N86 X12.0 Z4.5 T0500

N87 M30This program details the precise movements and offsets required for manual threading when the G76 cycle isn’t feasible. It ensures that the threading process remains accurate and controlled, even with the additional complexity of manual calculations.

Data Table for Offsets

To further illustrate the process, here’s a data table summarizing the offsets and starting positions:

| Pass | Depth per Side (units) | Offset (units) | Z-Axis Start Position |

|---|---|---|---|

| 1 | 0.0210 | 0.0000 | 0.2500 |

| 2 | 0.0087 | 0.0048 | 0.2548 |

| 3 | 0.0067 | 0.0037 | 0.2585 |

| 4 | 0.0056 | 0.0031 | 0.2616 |

| 5 | 0.0050 | 0.0028 | 0.2644 |

| 6 | 0.0040 | 0.0022 | 0.2666 |

This table provides a quick reference for the necessary offsets and positions, ensuring clarity and ease of use for the machinist.

Manual threading in CNC machining might be more labor-intensive than relying on automated cycles, but it offers unparalleled control and precision. By mastering the calculations and programming required for manual threading, machinists can tackle even the most complex jobs with confidence. The investment in time and effort pays off in the form of high-quality, precisely machined parts that meet the most exacting standards.

Other Articles You Might Enjoy

- Difference Between CNC and Manual Machining

Humans do not like change. Some people were unwilling to let go of their slide rules after calculators were created. While CNC machining has been around for decades, some still…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Exploring Different Dimension Formats in CNC Machining Parts Programming

In the world of CNC machining, how you input dimensions can significantly impact the ease and accuracy of your programming. Since CNC technology began being applied to real-world production in…

- Diving into Vertical CNC Machining Centers: From Programming to Specifications

When you step into a machine shop, the hum of CNC machines is a familiar sound. Among these, the vertical CNC machining center is a workhorse, particularly when it comes…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…