Introduction: Exploring Surface Treatment Technologies in CNC Machining

In the evolving landscape of CNC machining, surface treatment technologies like bead blasting and surface hardening are pivotal in enhancing the functionality and aesthetics of machined parts. These processes not only improve the visual appeal but also significantly bolster the durability and performance of components, catering to the rigorous demands of industries such as aerospace, automotive, and medical devices.

Importance of Surface Treatments

Surface treatments are essential for achieving desired finishes and improving resistance to wear, corrosion, and fatigue. This ensures that components can endure demanding operational environments, thereby extending their service life and reducing overall costs. The challenge lies in applying these treatments precisely and consistently, especially as parts become more complex.

Advancements and Sustainability

The drive towards sustainability is shaping the development of surface treatments, pushing for eco-friendly alternatives that maintain high performance. Innovations in bead blasting and surface hardening techniques have led to improved control over process parameters, allowing for enhanced consistency and adherence to environmental standards.In addition, the manufacturer provides online CNC service to facilitate customers to fully and accurately describe their “bead blasting” needs

Conclusion

Surface treatment technologies are integral to the success of CNC machining, offering solutions that meet the dual demands of performance and sustainability. The ongoing advancements in these techniques are crucial for the industry’s ability to produce high-quality, durable components.

Overview of Bead Blasting Technology

Bead blasting is a surface finishing process extensively used in CNC machining to enhance the aesthetic and functional quality of machined parts. This process involves propelling fine beads at high velocity towards the surface of the workpiece. The beads can be made of various materials, including glass, ceramic, and metal, each chosen based on the desired finish and material compatibility.

Principles and Benefits

The fundamental principle behind bead blasting lies in the kinetic energy of the beads. When these beads strike the surface, they gently remove surface deposits, such as oxides or scales, and smooth out surface irregularities. This results in a uniform, matte finish that not only improves the appearance of the part but also increases its resistance to corrosion and fatigue.

The benefits of bead blasting extend beyond just surface aesthetics. The process can also:

- Enhance the adhesion qualities of surfaces, making them more suitable for coatings and paints.

- Eliminate surface defects, reducing the risk of stress corrosion cracking in materials susceptible to this phenomenon.

- Improve surface texture, which is particularly beneficial for components requiring controlled friction properties.

Operational Considerations

Achieving optimal results with bead blasting requires careful consideration of various operational parameters, such as:

- Bead Material and Size: Selecting the appropriate bead material and size is crucial for achieving the desired surface finish without damaging the substrate.

- Blasting Pressure: The pressure at which the beads are propelled must be finely tuned to balance effective surface treatment with the preservation of the workpiece’s integrity.

- Angle and Distance of Blasting: The angle and distance from which the beads are directed at the workpiece can significantly affect the uniformity of the finish.

Case Study: Precision Instrument Finishing

A notable application of bead blasting was in the finishing process of precision surgical instruments. The manufacturer sought to achieve a consistent, non-reflective surface finish to reduce glare during surgical procedures. By employing fine glass beads under controlled blasting conditions, the instruments were finished to exact specifications, significantly improving their usability in sensitive medical environments.

Data Table: Bead Blasting Parameters and Outcomes

| Parameter | Setting | Outcome | Application |

|---|---|---|---|

| Bead Material | Glass | Smooth, matte finish | Aesthetic components |

| Bead Material | Ceramic | Aggressive cleaning | Rust removal |

| Pressure | Low (< 30 PSI) | Gentle surface cleaning | Delicate parts |

| Pressure | High (> 50 PSI) | Deep cleaning | Heavy contamination |

| Angle | 45° | Uniform finish | General purposes |

| Angle | 90° | Intense spot cleaning | Targeted areas |

| Distance | Close (< 12 inches) | Detailed finishing | Small components |

| Distance | Far (> 18 inches) | Broad coverage | Large surfaces |

By adjusting these parameters, bead blasting can be tailored to a wide range of applications, from delicate aerospace components requiring precise surface conditions to robust construction equipment needing extensive cleaning.

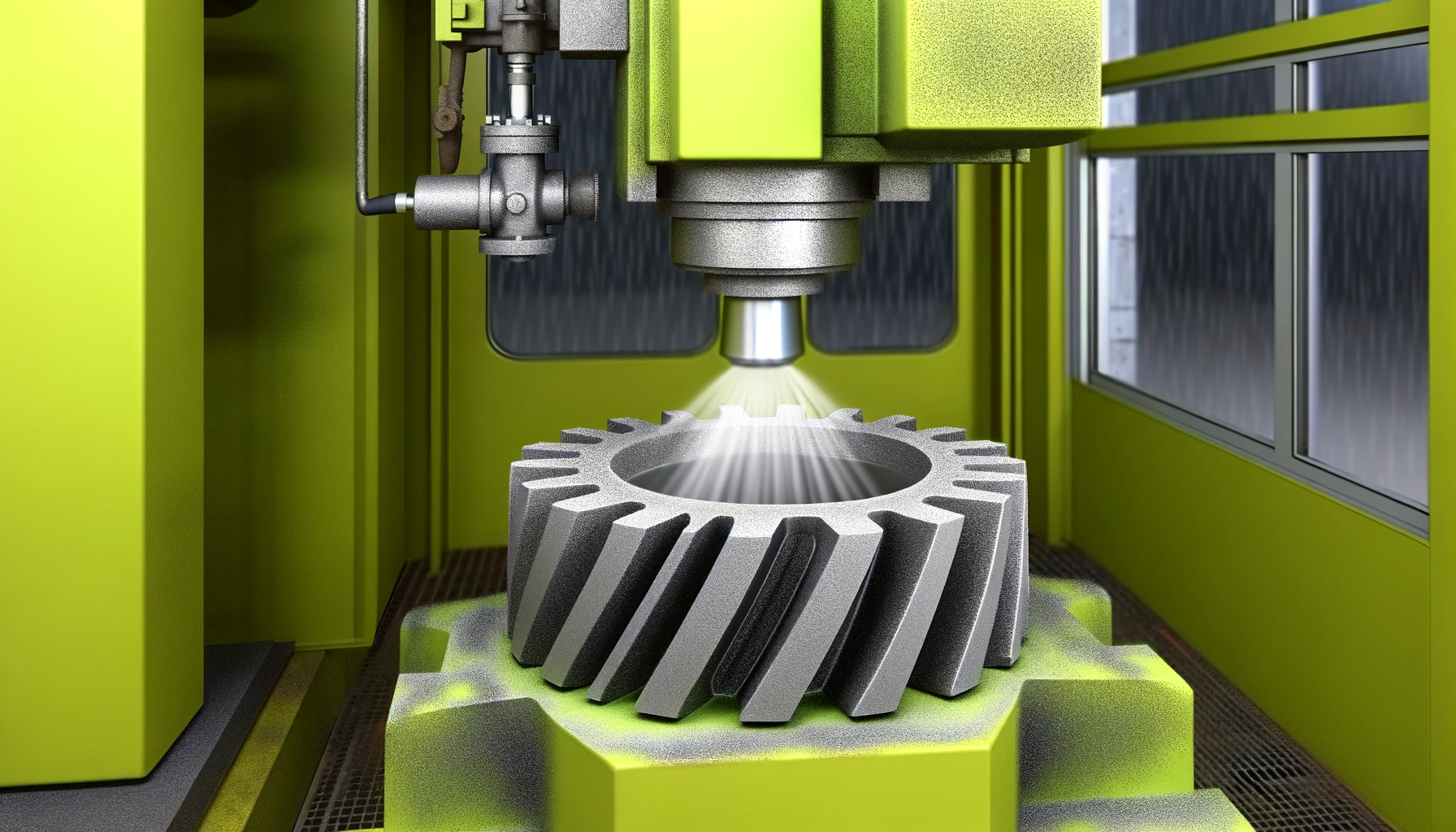

Application of Surface Hardening Techniques

Surface hardening techniques are critical in CNC machining for enhancing the wear resistance and longevity of machined components. These methods, including case hardening, nitriding, and induction hardening, involve altering the surface composition or structure of a material to increase its hardness.

Key Techniques and Their Applications

- Case Hardening: This process involves adding carbon to the outer layer of steel to improve hardness. It’s ideal for parts that require a hard exterior for wear resistance but a tough core to absorb impacts, such as gears and bearings.

- Nitriding: In this method, nitrogen is diffused into the surface of the steel, forming a hard layer. Nitriding is suitable for components that operate at high temperatures, as it provides high surface hardness without the need for quenching.

- Induction Hardening: This technique uses electromagnetic induction to heat the surface of a part quickly, followed by rapid cooling. It’s commonly used for parts requiring selective surface hardening, like shafts and spindles.

Data Table: Surface Hardening Techniques and Properties

| Technique | Hardness Increase | Depth of Hardening | Distortion Risk | Typical Applications |

|---|---|---|---|---|

| Case Hardening | Moderate | 0.1-0.5 mm | Low | Gears, Bearings |

| Nitriding | High | 0.05-0.7 mm | Very Low | Shafts, High-temp Components |

| Induction Hardening | High | 1-6 mm | Moderate | Axles, Rail Components |

| Carbonitriding | Moderate | 0.1-0.8 mm | Low | Small Parts, Fasteners |

| Flame Hardening | Variable | 1-10 mm | High | Large Gears, Rollers |

| Laser Hardening | High | 0.2-2 mm | Low | Precision Tools, Dies |

| Boriding (Boronizing) | Very High | 0.05-0.5 mm | Low | Cutting Tools, Wear Plates |

| Cryogenic Hardening | Variable | Entire Depth | Low | Tool Steels, Gears |

Challenges in Implementation

Implementing surface hardening techniques in CNC machining comes with its set of challenges, including controlling the depth and uniformity of the hardened layer, mitigating the risk of part distortion, and selecting the appropriate method for the material and application.

Technical Challenges and Solutions

Incorporating advanced surface treatment techniques such as bead blasting and surface hardening into CNC machining processes presents various technical challenges. These range from ensuring the uniform application of treatments to managing the potential impacts on material properties.

Overcoming Common Hurdles

Technical obstacles often include achieving consistent treatment depths, avoiding thermal distortion during hardening, and ensuring that the treated surfaces meet precise specifications. Solutions involve the use of advanced monitoring and control technologies, such as real-time temperature sensors during induction hardening or automated feedback systems in bead blasting equipment.

Case Study: Gear Manufacturing Precision

A manufacturer faced challenges with gear wear, leading to frequent replacements and downtime. By implementing a tailored induction hardening process, they achieved a significant increase in gear life, enhancing overall equipment reliability.

Case Study: Successful Integrated Application

The integration of bead blasting and surface hardening in CNC machining has led to notable successes in various industries. One such instance is in the automotive sector, where these techniques have been combined to produce high-performance engine components.

Enhancing Engine Component Lifespan

In this case, bead blasting was used to prepare the surface of engine valves, which were then subjected to a customized nitriding process. This combination not only improved the wear resistance of the valves but also significantly reduced the incidence of surface fatigue failures, contributing to longer engine life and better performance.

Conclusion and Future Perspectives

The advancements in surface treatment technologies, including bead blasting and surface hardening, are set to revolutionize CNC machining. These techniques offer the potential for significant improvements in the performance, durability, and functionality of machined parts.

Looking Ahead

Future developments may focus on the integration of AI and machine learning to further optimize these processes, reduce waste, and enhance customization. The continuous evolution of materials science also promises the development of new alloys and composites that will expand the possibilities for CNC machining and surface treatment technologies.

Other Articles You Might Enjoy

- Surface Refinement: Leveraging Bead Blasting for CNC Machining

In the realm of CNC machining, surface quality plays a pivotal role in determining the overall performance and aesthetics of the final product. Leveraging bead blasting as a surface refinement…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…