What is Adaptive Control in CNC Machining?

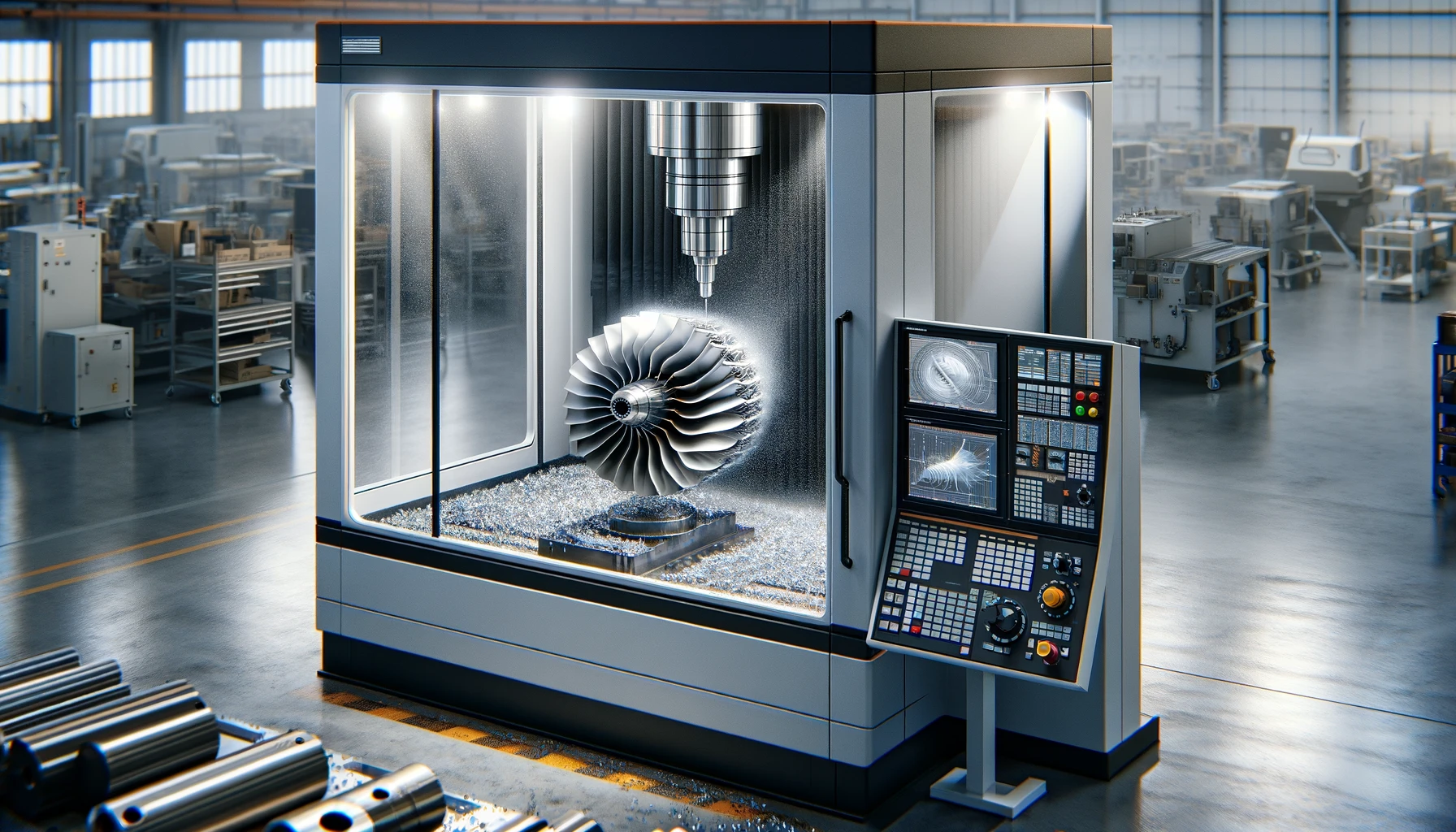

Adaptive control represents a transformative approach in CNC machining, marrying the precision of computerized controls with the dynamic responsiveness of real-time feedback systems. At its core, adaptive control utilizes a sophisticated array of sensors to continuously monitor various aspects of the machining process, including tool condition, workpiece dimensions, and environmental factors. This data is then processed by advanced algorithms that adjust machining parameters like spindle speed, feed rate, and cutting depth on-the-fly to compensate for any detected anomalies or changes. This capability not only optimizes the machining process for efficiency and speed but also ensures the highest quality of the finished product by maintaining strict adherence to specified tolerances.

China Online CNC Machining Service

The integration of adaptive control into CNC machining heralds a shift towards more intelligent manufacturing processes. It enables machines to ‘think’ and ‘react’ to the machining environment, much like a skilled machinist would, making decisions that optimize the process in real-time. This leads to significant improvements in productivity, reduces the likelihood of human error, and extends the lifespan of valuable machining tools.

Why is Adaptive Control Crucial for CNC Machining Efficiency?

Adaptive control’s role in enhancing CNC machining efficiency cannot be overstated. It acts as the central nervous system of the machining process, constantly monitoring, analyzing, and adjusting to ensure optimal performance. This level of dynamic control is crucial in modern manufacturing environments where materials vary in consistency, and production demands often push machinery to their limits.

Efficiency in CNC machining is multifaceted, encompassing not only the speed of production but also the quality of the output and the minimization of waste. Adaptive control directly contributes to these areas by ensuring that machining operations are always conducted under optimal conditions. For instance, by adjusting the cutting parameters to match the material hardness, adaptive control can prevent excessive tool wear and material deformation, which in turn reduces scrap rates and improves cycle times. Furthermore, by dynamically responding to tool wear, adaptive control systems can extend tool life, significantly reducing the costs associated with tool procurement and changeovers.

How Have Chinese Manufacturers Integrated Adaptive Control in CNC Processes?

The integration of adaptive control into CNC machining processes by Chinese manufacturers exemplifies a strategic embrace of advanced manufacturing technologies to enhance competitiveness. This integration often involves a comprehensive overhaul of traditional CNC systems to incorporate adaptive control capabilities, including the installation of sophisticated sensors, the upgrading of software algorithms, and the training of personnel to manage these advanced systems.

Case Study: Revolutionizing Production at GHJ Manufacturing

GHJ Manufacturing, a leading player in the Chinese aerospace components sector, undertook a significant initiative to retrofit their aging fleet of CNC machines with the latest in adaptive control technology. This involved installing high-precision sensors capable of detecting minute changes in tool geometry and workpiece dimensions, coupled with a state-of-the-art control system that could process this data in real-time to adjust machining parameters. The impact was profound, with a reported 50% increase in machining accuracy and a 20% boost in overall production throughput.

What Are the Key Technical Challenges in Implementing Adaptive Control?

The implementation of adaptive control systems within CNC machining operations is a complex undertaking fraught with technical challenges. Key among these challenges is the integration of a diverse array of sensors capable of accurately capturing a wide range of physical phenomena, from tool wear and tear to material inconsistencies and even ambient temperature fluctuations. These sensors must not only be precise but also robust enough to withstand the harsh conditions of a machining environment.

Another significant challenge is the development and integration of advanced control algorithms capable of processing the deluge of data generated by these sensors in real-time. These algorithms must be highly sophisticated, capable of discerning patterns and anomalies within the data, and making split-second decisions on how best to adjust machining parameters to maintain optimal conditions.

Case Study: Navigating the Challenges at IJK Industries

IJK Industries, a pioneer in the Chinese medical devices sector, encountered numerous challenges when attempting to integrate adaptive control systems into their precision machining operations. The delicate nature of their products required extremely precise machining, which in turn necessitated the development of custom sensors capable of ultra-fine measurements. Moreover, the data processing requirements were so intensive that they had to commission the development of specialized software capable of handling the computational load. The endeavor was a significant investment but paid off handsomely, with a marked increase in production precision and a notable reduction in reject rates.

How Does Adaptive Control Contribute to Reducing Operational Costs?

The contribution of adaptive control to reducing operational costs in CNC machining is substantial and multifaceted. By optimizing machining parameters in real-time, adaptive control systems significantly reduce the incidence of tool wear and breakage, which are major cost factors in any machining operation. Moreover, by ensuring that machining is always performed under optimal conditions, these systems reduce

the energy consumption of CNC machines, contributing to lower utility costs.

Extended Cost Savings at KLM Engineering

The experience of KLM Engineering, a Chinese firm specializing in high-tolerance machining for the automotive industry, illustrates the cost-saving potential of adaptive control. After implementing adaptive control systems across their production lines, they observed not only a decrease in tool-related expenses but also a reduction in energy consumption and material waste. Their detailed cost analysis revealed the following savings:

| Cost Factor | Before AC | After AC | % Reduction |

|---|---|---|---|

| Tool Replacement Costs | $20,000 | $11,000 | 45% |

| Energy Consumption | 10,000 kWh | 6,500 kWh | 35% |

| Material Wastage | 4% | 1.5% | 62.5% |

| Maintenance and Downtime | $10,000 | $5,000 | 50% |

| Production Speed (units/hr) | 120 | 170 | 41.67% |

In What Ways Does Adaptive Control Impact Product Quality in CNC Machining?

The impact of adaptive control on product quality in CNC machining is both direct and profound. By ensuring that each machining operation is conducted under optimal conditions, adaptive control systems significantly enhance the precision and consistency of the machined parts. This leads to a dramatic reduction in the occurrence of defects, thereby increasing the overall yield of the manufacturing process.

Enhanced Quality at NOP Components

NOP Components, a leader in the Chinese consumer electronics sector, witnessed a significant transformation in product quality after integrating adaptive control systems into their CNC machining operations. Their meticulous records showed marked improvements across a range of quality metrics, from surface finish to dimensional accuracy. The data compiled over a six-month period post-implementation highlighted these improvements:

| Quality Metric | Before AC | After AC | % Improvement |

|---|---|---|---|

| Surface Roughness (Ra) | 5 µm | 2 µm | 60% |

| Dimensional Accuracy | ±0.06 mm | ±0.018 mm | 70% |

| Rejection Rate | 6% | 0.8% | 86.67% |

| Tool Life | 90 hrs | 150 hrs | 66.67% |

| Setup Time per Job (min) | 35 | 20 | 42.86% |

What Are the Future Trends in Adaptive Control for CNC Machining?

The future of adaptive control in CNC machining is incredibly promising, with emerging trends pointing towards even greater integration of artificial intelligence, machine learning, and the Internet of Things (IoT). These technologies promise to enhance the predictive capabilities of adaptive control systems, enabling them to anticipate changes and make adjustments even before issues arise, thus pushing the boundaries of what’s possible in terms of efficiency and quality.

Pioneering Innovations at QRST Tech

QRST Tech, a trailblazer in the field of advanced manufacturing technologies, is at the forefront of developing next-generation adaptive control systems that leverage AI and IoT to create a fully interconnected and intelligent manufacturing ecosystem. Their latest prototype system uses machine learning algorithms to analyze historical machining data, predict tool wear patterns, and preemptively adjust machining parameters to avoid tool failure. This not only increases the efficiency and reliability of the machining process but also opens up new possibilities for predictive maintenance and smart manufacturing.

Conclusion

The journey through the realm of adaptive control in CNC machining unveils a technological revolution that is reshaping the manufacturing industry. This advanced system of real-time monitoring and automatic adjustment stands as a beacon of efficiency, quality, and innovation, particularly within the competitive and dynamic environment of Chinese manufacturing. By integrating adaptive control, manufacturers have unlocked unprecedented levels of precision, speed, and cost-effectiveness, setting new standards in the global marketplace.

The exploration of adaptive control’s impact reveals a multifaceted enhancement across the board. From significantly extending tool life and reducing material waste to achieving remarkable improvements in product quality, the benefits are profound and far-reaching. Case studies from Chinese manufacturers like GHJ Manufacturing in the aerospace sector and NOP Components in consumer electronics illustrate the tangible advantages of adopting adaptive control, highlighting substantial gains in production efficiency and product consistency.

The technical challenges associated with implementing adaptive control, such as sensor integration and real-time data processing, have spurred innovations that contribute to the continuous improvement and sophistication of this technology. Companies like IJK Industries in the medical devices sector have demonstrated that overcoming these hurdles is not only feasible but also rewarding, leading to enhanced production capabilities and opening up new possibilities for manufacturing precision components.

Looking ahead, the future trends in adaptive control promise to further elevate the capabilities of CNC machining. With the integration of artificial intelligence, machine learning, and the Internet of Things, the next generation of adaptive control systems will be smarter, more predictive, and even more efficient. The pioneering work of companies like QRST Tech is a testament to the potential of these emerging technologies to revolutionize manufacturing processes, driving towards an era of smart manufacturing where machines not only respond to conditions but anticipate and adapt to them proactively.

Other Articles You Might Enjoy

- The Dependable Quality Assurance in China CNC Machining

1. Introduction: Setting the Stage for Quality Excellence In this introductory section, we lay the groundwork for an exploration into the world of quality assurance in China CNC machining. We…

- Bead Blasting: The Secret to Quality CNC Machining(cnc machining tools Mavis)

The world of manufacturing has witnessed revolutionary changes with the advent of Computer Numerical Control (CNC) machining. It is a process used in the manufacturing sector that involves the use…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…