What Are the Unique Challenges of Milling Titanium?

Titanium is a highly desirable material in many industries due to its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. However, its unique properties also present significant challenges during the milling process.

Heat Generation and Dissipation: One of the primary challenges in milling titanium is the heat generated during the cutting process. Titanium has low thermal conductivity, meaning the heat tends to stay concentrated around the cutting area. This can lead to tool wear and potential deformation of the material.

Tool Wear: The hardness and abrasiveness of titanium contribute to rapid tool wear. This requires frequent tool changes, increasing downtime and operational costs.

Work Hardening: Titanium has a tendency to work harden, which can cause difficulties in machining as the material becomes harder with each pass of the cutting tool. This demands more robust tooling and careful process planning.

Case Study: Aerospace Industry

In the aerospace industry, where precision and reliability are paramount, companies have adopted specialized cooling systems and coatings on tools to manage the heat and reduce wear when milling titanium parts. These innovations have allowed for more efficient and cost-effective production processes.

How Do Cutting Parameters Affect the Milling of Titanium Parts?

The selection of cutting parameters—such as speed, feed rate, and depth of cut—plays a critical role in the milling of titanium parts. Optimizing these parameters can significantly impact tool life, surface finish, and overall efficiency.

Cutting Speed: Lower cutting speeds are typically used for titanium to prevent excessive heat generation. However, too low a speed can reduce efficiency, so a balance must be struck.

Feed Rate: The feed rate needs to be optimized to ensure a consistent cutting force. Too high a feed rate can lead to tool breakage, while too low a rate can result in work hardening.

Depth of Cut: The depth of cut should be carefully controlled to manage the amount of material being removed and to minimize tool deflection.

Data Table: Optimal Cutting Parameters for Titanium Milling

| Parameter | Recommended Value | Effect on Tool Life | Effect on Surface Finish |

|---|---|---|---|

| Cutting Speed | 30-50 m/min | Increases | Improved |

| Feed Rate | 0.1-0.2 mm/rev | Balanced | Enhanced |

| Depth of Cut | 1-3 mm | Maximizes | Optimal |

| Coolant Usage | High Pressure | Reduces Wear | Better Cooling |

| Tool Material | Carbide, Cobalt | Longer Lifespan | Smooth Finish |

| Coating | TiAlN, TiCN | Extends Life | Reduced Friction |

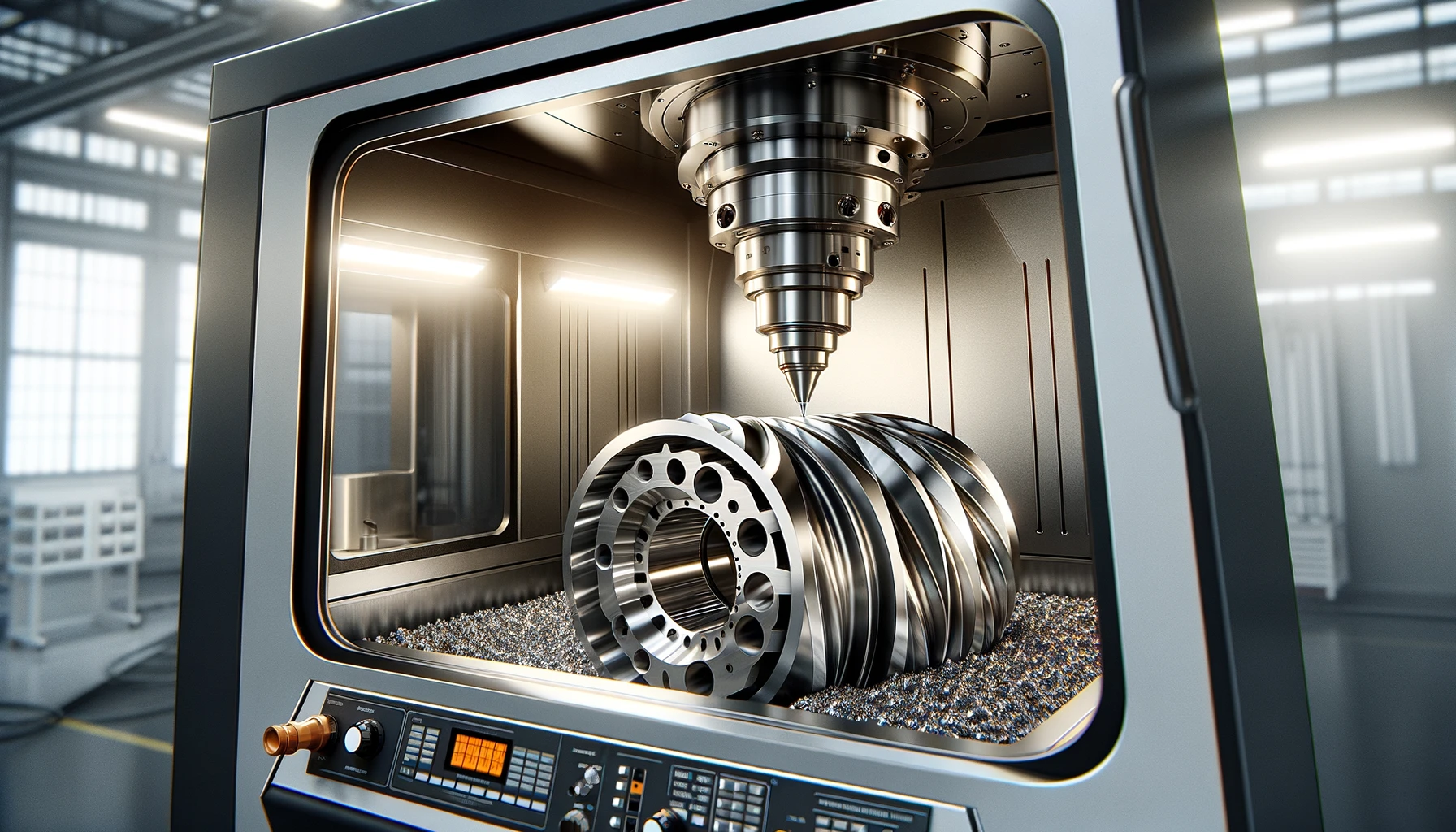

What Innovations in CNC Milling Technology Improve Titanium Part Production?

Recent advancements in CNC milling technology have addressed many of the challenges associated with machining titanium, leading to improved efficiency and cost-effectiveness.

High-Speed Machining (HSM): HSM techniques involve using higher spindle speeds with lower feed rates, allowing for more precise and efficient milling. This reduces the heat buildup and improves tool life.

Cryogenic Machining: This technique uses liquid nitrogen to cool the cutting area, significantly reducing the thermal impact on the tool and workpiece. Cryogenic machining has shown to extend tool life and improve surface quality.

Adaptive Control Systems: These systems adjust the cutting parameters in real-time based on feedback from the machining process. This helps in maintaining optimal conditions, reducing tool wear, and preventing work hardening.

Case Study: Medical Device Manufacturing

A medical device manufacturer implemented cryogenic machining for milling titanium components used in surgical instruments. This innovation led to a 40% increase in tool life and a 30% reduction in production costs, demonstrating the significant impact of advanced milling technologies.

How Does Tooling Selection Impact the Milling of Titanium Parts?

Choosing the right tools for milling titanium is crucial for achieving high-quality parts while maintaining cost-effectiveness. Several factors must be considered, including tool material, coating, geometry, and the use of specialized tools.

Tool Material: Carbide tools are commonly used for titanium milling due to their hardness and wear resistance. Cobalt-based tools are also effective but tend to be more expensive.

Tool Coating: Coatings like Titanium Aluminum Nitride (TiAlN) and Titanium Carbon Nitride (TiCN) provide a protective layer that reduces friction and enhances tool life.

Tool Geometry: The geometry of the cutting tool, including the rake angle, relief angle, and flute design, plays a critical role in efficient chip evacuation and reducing cutting forces.

Specialized Tools: High-performance end mills and inserts designed specifically for titanium can greatly improve machining efficiency and surface finish.

Data Table: Comparison of Tooling Options for Titanium Milling

| Tool Type | Material | Coating | Ideal Applications | Pros | Cons |

|---|---|---|---|---|---|

| End Mills | Carbide | TiAlN | Finishing, Roughing | High wear resistance | Higher initial cost |

| Inserts | Cobalt | TiCN | Heavy Cutting | Excellent toughness | More expensive |

| High-Speed Steel | HSS | None | General Use | Cost-effective | Shorter tool life |

| Diamond Coated | Carbide | Diamond | Precision Work | Exceptional durability | Very high cost |

| Ball Nose End Mill | Carbide | TiAlN | Contour Milling | Superior surface finish | Limited applications |

What Role Does CNC Software Play in Enhancing Titanium Part Production?

The software used in CNC machining is as critical as the hardware. Advanced software solutions can optimize tool paths, simulate machining processes, and enhance overall productivity.

CAD/CAM Software: Integrated CAD/CAM software allows for seamless transition from design to manufacturing. These systems can optimize tool paths to reduce machining time and improve precision.

Simulation Tools: CNC simulation software can predict potential issues in the machining process before actual production, saving time and reducing material waste.

Process Monitoring: Real-time monitoring systems track tool wear, cutting forces, and other critical parameters, allowing for immediate adjustments to maintain optimal machining conditions.

Case Study: Automotive Component Production

An automotive company adopted advanced CAD/CAM software to produce complex titanium components for high-performance engines. By optimizing the tool paths and using real-time process monitoring, they reduced production time by 25% and significantly lowered defect rates.

How Can Quality Control Measures Improve the Production of Titanium Parts?

Quality control is vital in the production of titanium parts to ensure they meet stringent industry standards. Implementing robust quality control measures can prevent defects and reduce costs.

In-Process Inspection: Automated in-process inspection systems can detect deviations in real-time, allowing for immediate corrective actions. This reduces the risk of producing defective parts.

Post-Process Quality Checks: Comprehensive post-process inspections, including dimensional checks and surface finish evaluations, ensure that the final products meet the required specifications.

Statistical Process Control (SPC): Using SPC tools to monitor and control the machining process can help in maintaining consistency and identifying trends that may lead to quality issues.

Case Study: Quality Control in Aerospace Manufacturing

An aerospace manufacturer implemented in-process inspection and SPC for their titanium part production. This approach led to a 50% reduction in defects and improved overall product quality, demonstrating the effectiveness of stringent quality control measures.

Focusing on these critical aspects, businesses can leverage CNC milling technology to enhance the production of titanium parts, ensuring high quality and cost-effectiveness.

Other Articles You Might Enjoy

- CNC Milling: Revolutionizing Automotive Part Production

When it comes to versatile materials, few can match the capabilities of aluminum. Its lightweight and flexible nature make it an ideal choice for various industries, including automotive, aerospace, and…

- 3 Types of CNC Milling Machines: Process & Production

What Is CNC Milling Machining Process? CNC milling is a process that uses rotating cutters to gradually remove material from a block until the required customs form is created. It…

- Custom CNC Machining Services for Titanium Parts: Enhancing Aerospace and Medical Industries?

Custom CNC Machining in the Aerospace and Medical Sectors In response to the steady growth of both the aerospace and medical industries, increasingly sophisticated manufacturing techniques have become a necessity.…

- Titanium Parts CNC Machining: Advancements and Applications in Medical Device Manufacturing

Titanium Parts CNC Machining in Medical Device Manufacturing As a cornerstone of medical manufacturing, the combination of Titanium parts and Computer Numerical Control (CNC) machining bring immense value to this…

- Unraveling the World of CNC Machined Plastic Parts(CNC machined plastic parts Mabel)

Modern innovations have taken traditional manufacturing methods to new heights. One such innovation that stands out is Computer Numerical Control (CNC) machining, a process used extensively in various industries from…

- CNC Machined Plastic Parts: An In-depth Overview(CNC machined plastic parts Norman)

Computer Numeric Control (CNC) machining is an advanced manufacturing process where pre-programmed software dictates the movement of factory machinery and tools. These applications can carry out complicated manufacturing tasks with…