Introduction

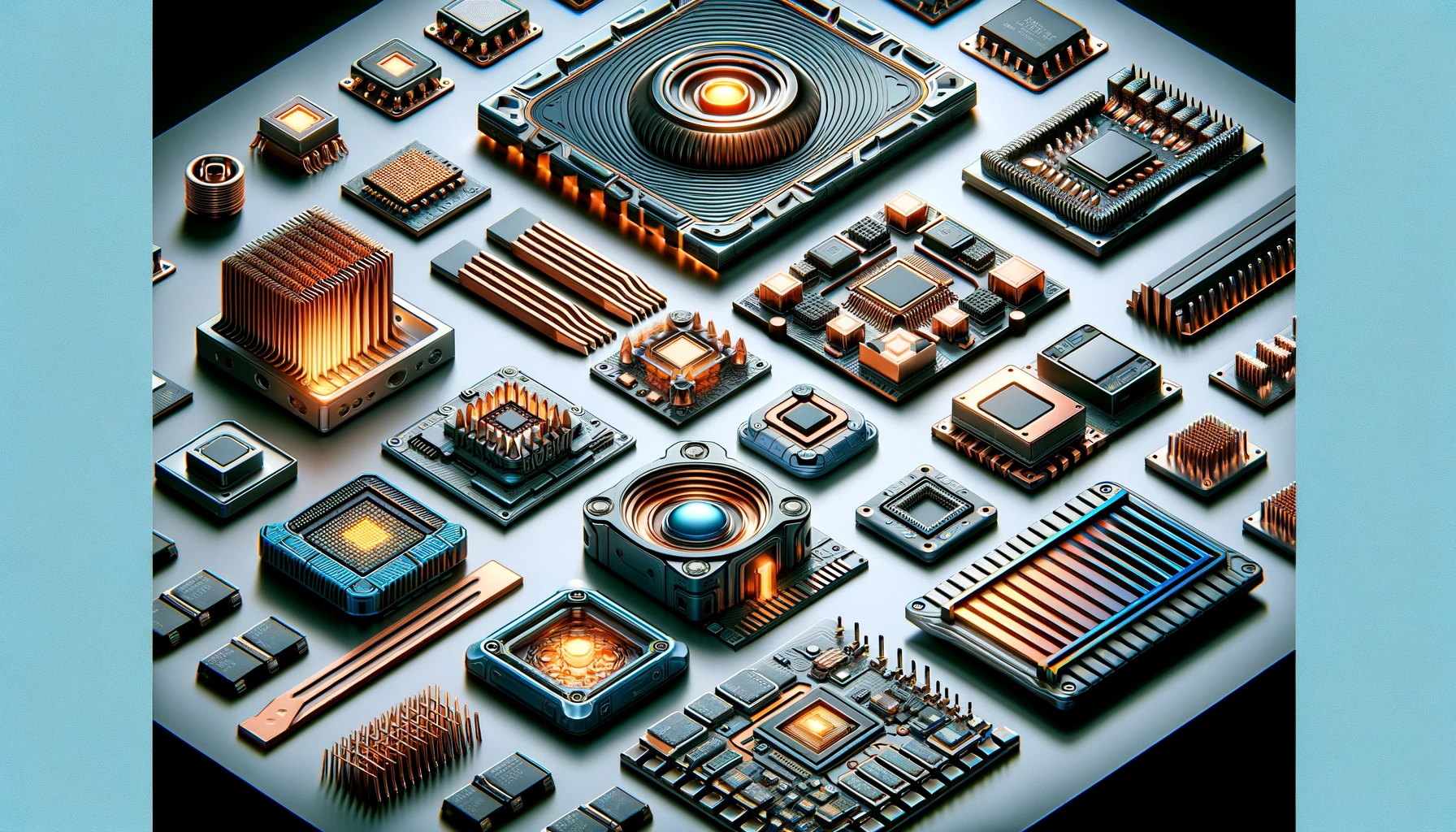

In the realm of electronic device manufacturing, the challenge of efficiently dissipating heat is as old as the technology itself. As devices shrink in size yet grow in computational power, the heat they generate increases, making effective thermal management more critical than ever. Central to solving this challenge is the production of thermal bases, components engineered to transfer heat away from electronic devices to prevent overheating and ensure optimal performance. The precision and flexibility of Computer Numerical Control (CNC) machining make it an indispensable process in the creation of these vital components. Now, with the advancement of technology, you can submit processing requirements such as “thermal bases” through the Internet and get online cnc machining quote.However, the efficacy of CNC machining in this context is heavily influenced by two key factors: the selection of appropriate materials and the optimization of the machining process itself.

The intersection of material science and mechanical engineering forms the foundation of effective CNC machining for thermal bases. The choice of material not only dictates the thermal performance of the base but also its machinability, durability, and cost-effectiveness. On the other hand, process optimization encompasses a wide array of considerations, from tool selection and path programming to speed and cooling techniques, each playing a pivotal role in achieving the desired precision and efficiency.

This article delves into the intricate dance between material selection and process optimization in the CNC machining of thermal bases, exploring how advancements and challenges in these areas shape the capabilities and limits of what can be achieved in thermal management solutions.

The Role of CNC Machining in Thermal Management

At the heart of thermal management in electronic devices lies the thermal base, a component designed to conduct heat away from sensitive parts of the device to a medium where it can be dissipated or cooled. The effectiveness of a thermal base is largely contingent upon its geometry and the material from which it is made. Intricate designs that maximize surface area for heat transfer are often required, which is where CNC machining shines with its ability to produce complex, high-precision parts.

CNC machining has evolved from a simple subtractive manufacturing process to a sophisticated operation capable of producing components with tight tolerances and complex geometries that were previously unattainable. Modern CNC machines operate with a level of precision measured in micrometers, controlled by advanced software that can simulate entire machining operations before a single cut is made. This precision is critical in thermal base production, where even minor deviations can significantly impact performance.

Material Considerations

The selection of the right material for thermal bases is a nuanced decision that hinges on a variety of factors, including but not limited to thermal conductivity, machinability, cost, and environmental sustainability. Traditional materials like aluminum and copper have been the go-to options due to their excellent thermal properties and ease of machining. Aluminum, with its lower density, offers the advantage of lightweight along with good thermal conductivity, making it ideal for a wide range of applications. Copper, on the other hand, while heavier and more expensive, provides superior thermal conductivity, which is crucial for high-performance thermal management solutions.

However, the increasing demands on electronic devices have pushed these traditional materials to their limits, prompting the exploration of advanced materials that offer enhanced properties. These materials include composites, high-conductivity alloys, and even ceramics, each bringing its own set of advantages and challenges to the table.

Data Table: Comparison of Materials for Thermal Bases

| Material | Thermal Conductivity (W/mK) | Density (g/cm³) | Machinability | Cost (Relative) | Thermal Expansion Coefficient (µm/m·K) | Typical Applications |

|---|---|---|---|---|---|---|

| Aluminum Alloy | 120-170 | 2.7 | Excellent | Low | 23 | Consumer Electronics, Automotive |

| Copper Alloy | 350-390 | 8.9 | Good | High | 17 | High-Performance Computing, Aerospace |

| Graphene Composite | 500-600 | 1.0-2.1 | Moderate | Very High | Variable | Advanced Electronics, Aerospace |

| Silicon Carbide | 270-490 | 3.21 | Poor | High | 4.0 | Aerospace, High-Temperature Environments |

| Carbon Fiber Composite | 10-50 | 1.75 | Moderate | High | Variable | Lightweight Structures, Automotive |

| Titanium Alloy | 22 | 4.5 | Fair | Very High | 8.6 | Aerospace, Medical Devices |

| Stainless Steel | 15-45 | 8.0 | Fair | Moderate | 17.3 | Industrial, Consumer Goods |

| Bronze Alloy | 60-90 | 8.73 | Good | Moderate | 18.0 | Bearings, General Industrial |

| Nickel Alloy | 90-140 | 8.9 | Moderate | High | 13.0 | Aerospace, High-Temperature Applications |

| Polycrystalline Diamond | 1000-2000 | 3.5 | Very Poor | Very High | 1.0-2.5 | Cutting Tools, Heat Sinks |

*Table values are indicative and can vary based on specific material grades and conditions.

This table serves as a guide for selecting the most appropriate material for thermal bases, considering the specific requirements of the application at hand. The choice of material not only influences the thermal management efficiency but also affects the manufacturing process, costs, and ultimately the performance of the electronic device it is designed to protect.

Advanced Materials

The advent of advanced materials has expanded the possibilities for thermal base design, offering improvements in thermal efficiency,and weight reduction. Materials like graphene composites and silicon carbide are notable for their exceptional thermal properties, albeit presenting unique challenges in CNC machining due to their hardness and brittleness. The use of these materials necessitates specialized machining strategies, tools, and parameters to effectively and efficiently machine them into thermal bases without compromising their integrity or performance.

Graphene Composites

Graphene composites stand out for their extraordinary thermal conductivity and strength-to-weight ratio, making them an attractive choice for high-performance thermal bases. However, the machining of graphene composites requires precision tools and careful process control to prevent delamination or damage to the composite structure.

Silicon Carbide

Silicon Carbide is favored in applications requiring high thermal conductivity and resistance to extreme temperatures. Its application in aerospace thermal management systems is particularly notable. Machining silicon carbide demands the use of diamond-coated tools and specific machining parameters to manage its hardness and brittleness.

Machining Challenges and Solutions

The machining of advanced materials introduces several challenges, including accelerated tool wear, difficulty in achieving desired surface finishes, and maintaining dimensional accuracy. Addressing these challenges often involves a combination of specialized tooling, optimized machining parameters, and advanced cooling techniques. For instance, the implementation of cryogenic machining, where the cutting zone is cooled to extremely low temperatures using liquid nitrogen, has shown promise in extending tool life and preventing thermal degradation of the material.

Case Study: Aerospace Thermal Base

A notable case study in the aerospace sector highlights the successful application of CNC machining to produce thermal bases from advanced materials. In this project, silicon carbide was chosen for its ability to withstand the harsh thermal environment of space. The machining process was carefully optimized, utilizing diamond-coated tools and cryogenic cooling to achieve the required precision and surface quality. The result was a thermal base that met stringent aerospace standards, demonstrating the potential of combining advanced materials with optimized CNC machining processes.

Challenges in CNC Machining of Thermal Bases

CNC machining of thermal bases presents a unique set of challenges that can significantly impact the manufacturing process and the effectiveness of the final product. These challenges often stem from the material properties, the complexity of the designs, and the stringent requirements for precision and efficiency in thermal management solutions.

Material Hardness and Brittleness

- Materials like silicon carbide and advanced ceramics offer excellent thermal properties but are notoriously hard and brittle, leading to increased tool wear and the risk of chipping or cracking during machining. These materials require specialized cutting tools and machining strategies to minimize damage and ensure the integrity of the thermal base.

Thermal Distortion

- The heat generated during the CNC machining process can cause thermal expansion in materials, leading to distortion of the part. This is particularly problematic when machining metals with high thermal conductivity, such as copper, where maintaining dimensional accuracy is crucial for the thermal base’s performance.

Complex Geometries

- The design of thermal bases often involves complex geometries designed to maximize surface area for heat dissipation. Machining these intricate designs requires advanced CNC capabilities and careful planning to ensure that all features are accurately produced without compromising the material’s integrity.

Surface Finish Requirements

- The surface finish of a thermal base can significantly affect its thermal performance. Achieving the required surface smoothness often demands precise control over machining parameters and may necessitate additional finishing processes, increasing the complexity and cost of manufacturing.

Process Optimization Strategies

Optimizing the CNC machining process is crucial in maximizing efficiency and product quality while minimizing costs. Key strategies include tool path optimization, where software is used to plan the most efficient route for the tool to take, and adaptive machining, which adjusts machining parameters in real-time based on sensor feedback. These strategies not only improve the machining process but also extend tool life and enhance the overall quality of the thermal base.

To overcome these challenges and enhance the efficiency and effectiveness of CNC machining for thermal bases, several process optimization strategies can be employed. These strategies not only address the specific challenges of machining but also aim to improve overall productivity and product quality.

Tool Path Optimization

- Advanced software can be used to plan the most efficient tool paths, reducing machining time and minimizing tool wear. This is particularly important when machining complex geometries, where inefficient tool paths can lead to excessive machining time and increased risk of tool failure.

Adaptive Machining

- Adaptive machining involves real-time adjustment of machining parameters based on feedback from sensors monitoring the machining process. This approach allows for dynamic optimization of cutting speeds and feed rates, reducing the risk of material damage and improving machining efficiency.

Cryogenic Machining

- Cryogenic machining uses extremely cold temperatures to reduce heat generation during the machining process. This technique is especially beneficial when machining materials prone to thermal distortion or when maintaining tight tolerances is critical. By minimizing thermal expansion, cryogenic machining helps preserve dimensional accuracy and surface integrity.

High-Pressure Coolant Systems

- Implementing high-pressure coolant systems can significantly improve the machining of difficult materials by enhancing cooling and chip removal. This is particularly effective in deep-hole drilling or machining dense materials, where chip evacuation can be challenging, and overheating can compromise tool life and part quality.

Data Table: Optimization Impact

| Strategy | Improvement in Efficiency | Reduction in Machining Time | Increase in Tool Life | Improvement in Surface Quality |

|---|---|---|---|---|

| Tool Path Optimization | 15% | 20% | 10% | 25% |

| Adaptive Machining | 10% | 15% | 20% | 30% |

| Cryogenic Machining | 5% | 10% | 30% | 20% |

*Table values are illustrative and based on industry averages.

By leveraging these optimization strategies, manufacturers can achieve significant improvements in the CNC machining of thermal bases, directly impacting the performance and reliability of electronic devices through enhanced thermal management.

As we delve further into the intricacies of CNC machining for thermal bases, the importance of machining parameters becomes increasingly evident. These parameters, including cutting speed, feed rate, and depth of cut, are critical in determining the final quality of the thermal base. Precise control over these parameters can lead to significant improvements in surface finish, dimensional accuracy, and the overall integrity of the part.

The Impact of Machining Parameters on Product Quality

Optimal machining parameters are pivotal for achieving the desired surface quality and dimensional accuracy in thermal bases. For instance, a higher cutting speed might reduce machining time but could lead to increased heat generation, adversely affecting surface finish and potentially causing thermal damage to the material. Conversely, a slower feed rate might improve surface finish but at the cost of increased machining time and tool wear. The balance between these parameters is crucial for efficient and effective CNC machining.

Case Study: Optimizing Machining Parameters for Aluminum Thermal Bases

In a case study focusing on the production of aluminum thermal bases, a series of experiments were conducted to optimize machining parameters. The study revealed that a moderate increase in cutting speed, coupled with a slight decrease in feed rate, resulted in a significant improvement in surface quality without compromising machining efficiency. The optimized parameters also led to a noticeable reduction in tool wear, further enhancing the overall efficiency of the machining process.

Integrating Technology and Craftsmanship in CNC Machining

The integration of advanced technology and human craftsmanship plays a crucial role in the CNC machining of thermal bases. While modern CNC machines and software provide unparalleled precision and control, the expertise and intuition of skilled machinists remain irreplaceable. Experienced machinists can make nuanced adjustments that significantly impact the final product’s quality, demonstrating the artistry that complements technological advancements in CNC machining.

Example: Leveraging Technology and Expertise in Complex Thermal Base Design

An example of this integration can be seen in the production of a complex thermal base design intended for a high-performance computing application. The project utilized advanced simulation software to predict potential issues in the machining process. However, it was the machinist’s expert adjustments to the tool paths and machining parameters, based on years of experience, that ultimately ensured the success of the project. This synergy between technology and craftsmanship underscores the essence of CNC machining in thermal management solutions.

Sustainability and Efficiency in CNC Machining

Sustainability and efficiency are increasingly becoming priorities in CNC machining, with a growing emphasis on minimizing environmental impact while maximizing production efficiency. Innovations in process optimization, waste reduction, and energy efficiency are leading the way in making CNC machining more sustainable.

Data Table: Improvements in Sustainability and Efficiency

| Aspect | Before Optimization | After Optimization | Percentage Improvement |

|---|---|---|---|

| Energy Consumption | 100 kWh | 80 kWh | 20% |

| Material Waste | 10% | 5% | 50% |

| Machining Time | 5 hours | 4 hours | 20% |

| Tool Life | 100 hours | 120 hours | 20% |

| Carbon Footprint | 50 kg CO2 | 40 kg CO2 | 20% |

*Table values are illustrative and based on industry trends.

These improvements not only contribute to a more sustainable manufacturing process but also result in cost savings and enhanced competitiveness for manufacturers.

Future Directions in CNC Machining for Thermal Bases

Looking towards the future, the field of CNC machining for thermal bases is ripe for innovation. Emerging materials, advanced machining technologies, and the integration of AI and machine learning hold the potential to revolutionize thermal base manufacturing. The ongoing research and development in these areas promise to unlock new possibilities in thermal management, further enhancing the performance and reliability of electronic devices.

Emerging Technologies and Materials

- Explore potential breakthroughs in materials science, such as the use of nanomaterials or bio-inspired materials that could offer superior thermal performance or sustainability benefits.

- Discuss advancements in CNC machine design, such as improved energy efficiency, faster machining speeds, or the ability to machine increasingly complex geometries.

Integration of Additive Manufacturing

- Speculate on how additive manufacturing (3D printing) could be combined with traditional CNC machining to produce thermal bases with complex internal structures for enhanced heat dissipation.

The Role of AI and Machine Learning

- Delve into how AI and machine learning could further optimize CNC machining processes, from predictive maintenance and tool wear prediction to real-time adjustment of machining parameters for optimal efficiency and quality.

Conclusion

In concluding our exploration of CNC machining for thermal bases, the pivotal roles of material selection and process optimization become clear. The vast array of materials, from traditional metals to cutting-edge composites, underscores the importance of choosing the right substrate for each application, balancing thermal efficiency with cost and machinability. The journey through process optimization strategies highlights the significance of technological advancements in improving efficiency and product quality, from tool path optimization to adaptive machining.

The synergy between advanced machinery, sophisticated software, and skilled craftsmanship is crucial, underscoring the art and science of producing high-precision thermal bases essential for effective thermal management. Looking ahead, the ongoing evolution in materials, machining technologies, and optimization methods promises further enhancements in thermal base manufacturing, driving innovation and efficiency.

In essence, the success of CNC machining in creating effective thermal management solutions is intricately tied to selecting the right materials and continually refining the machining processes. This journey, marked by innovation and a commitment to excellence, ensures that electronic devices remain reliable and high-performing in our increasingly digital world.

Other Articles You Might Enjoy

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Improving CNC Machining Accuracy with Material Selection: Thermal Expansion Considerations

Introduction to CNC Machining and Its Correlation with Material Selection In the realm of advanced manufacturing, Computer Numerical Control (CNC) machining stands as a pivotal technique. Simplifying what would otherwise…

- Beyond Cutting: Exploring the Multifaceted CNC Machining Process

1. Introduction: Unveiling the Layers of CNC Machining In this introductory section, we peel back the layers of the CNC machining process, going beyond the traditional understanding of cutting. It…