Understanding the Complexity of Food Automation Machinery Molds

The complexity of molds used in food automation machinery cannot be overstated. These molds must not only accurately shape food products but also withstand the rigors of continuous production cycles. The intricate designs required for these molds demand a level of precision that only advanced CNC machining can provide. Factors such as the thermal expansion of materials, the fluid dynamics of molten food products, and the ease of demolding are critical considerations that affect the mold’s design and functionality.

Case Study: Design and Fabrication of a Chocolate Molding Machine

A prominent chocolate manufacturer was facing inefficiencies in their production line due to frequent mold replacements and maintenance. The existing molds were not durable enough and lacked the precision needed for complex chocolate shapes. After consulting with a top-tier CNC machining service in China, they embarked on a project to redesign and fabricate new molds. The service provider employed high-precision CNC milling machines and selected a premium aluminum alloy known for its excellent thermal properties and durability. The new molds were also treated with a non-stick coating, significantly reducing the release time of chocolate pieces and minimizing production stoppages. This collaboration resulted in a 25% boost in production efficiency, a notable reduction in maintenance downtime, and an overall improvement in the quality of the chocolate products.

Why Is Material Selection Crucial for Mold Efficiency?

Choosing the right material for food automation machinery molds is a complex decision that influences the mold’s longevity, efficiency, and even the safety of the food products. Materials must be selected based on their mechanical properties, compatibility with food products, and their behavior under the specific conditions of food processing, such as exposure to high temperatures or corrosive food substances.

Data Table: Comparison of Materials Used in Food Automation Machinery Molds

| Material | Corrosion Resistance | Thermal Conductivity | Cost | Durability | Food Safety |

|---|---|---|---|---|---|

| Stainless Steel | Excellent | Low (16 W/mK) | High | Very High | Excellent |

| Aluminum | Good | High (205 W/mK) | Moderate | Good | Good |

| Composites | Excellent | Variable | Very High | High | Excellent |

| Bronze | Good | Moderate (110 W/mK) | High | Very High | Good |

| PEEK | Good | Low (0.25 W/mK) | Very High | High | Excellent |

| Polycarbonate | Moderate | Low (0.2 W/mK) | Moderate | Moderate | Good |

| Teflon (PTFE) | Excellent | Low (0.25 W/mK) | High | High | Excellent |

This table provides an overview of the various materials available for mold making, highlighting their key properties and suitability for use in food automation machinery. The choice of material directly impacts the mold’s performance in terms of heat transfer, resistance to wear and tear, and its ability to produce safe food products.

What Are the Key Design Considerations for High-Performance Molds?

Designing molds for high-performance in food automation machinery requires meticulous attention to detail. Every aspect of the mold, from its overall geometry to the minutiae of its surface texture, must be engineered to optimize the production process. This involves considerations like ensuring uniform heat distribution across the mold, designing for rapid cooling to minimize cycle times, and incorporating features that facilitate easy release of the finished product.

Case Study: Optimization of Injection Mold Design for Improved Productivity

In an effort to enhance the efficiency of their beverage bottling line, a multinational corporation sought the expertise of a leading CNC machining service in China. The objective was to redesign the injection mold used for producing plastic bottle caps. The existing mold was causing bottlenecks due to slow cooling times and frequent cap sticking issues. The collaborative design process focused on optimizing the mold’s cooling channels to achieve faster thermal dissipation. Additionally, the cap release mechanism was re-engineered to include air-assist ejection, significantly reducing the force required to eject the caps and thereby increasing the mold’s operational speed. The redesigned mold not only increased the production rate by 30% but also extended the mold’s service life by reducing wear on critical components.

How Can Surface Treatment Techniques Impact Mold Longevity and Efficiency?

Surface treatment techniques play a crucial role in enhancing the performance and longevity of molds used in food automation machinery. These treatments can significantly improve the mold’s resistance to wear and corrosion, reduce adhesion between the mold and the food product, and facilitate easier cleaning and maintenance. Techniques such as anodizing, hard coating, and the use of non-stick coatings are commonly employed to achieve these goals. Each of these treatments can be tailored to meet the specific requirements of the mold’s application, taking into consideration the type of food product, the operational temperatures, and the cleaning processes involved.

Data Table: Surface Treatment Methods and Their Effects on Mold Performance

| Treatment Type | Wear Resistance | Friction Coefficient | Food Safety | Application Ease | Cost |

|---|---|---|---|---|---|

| Anodizing | High | Low (0.1-0.3) | Excellent | Moderate | Moderate |

| Hard Coating | Very High | Very Low (<0.1) | Excellent | High | High |

| Non-Stick Coating | Moderate | Very Low (<0.1) | Excellent | Moderate | Moderate |

| Electroplating | High | Low (0.2-0.4) | Good | High | Moderate |

| Powder Coating | Moderate | Low (0.2-0.5) | Good | Moderate | Low |

| Laser Engraving | Moderate | N/A | Excellent | High | High |

| Chemical Etching | High | N/A | Excellent | Moderate | Moderate |

This table elucidates the diverse range of surface treatment options available for mold manufacturers, highlighting their impact on wear resistance, ease of product release, and compatibility with food safety standards. The choice of surface treatment can significantly affect the mold’s operational efficiency and maintenance requirements.

Why Partnering with the Right CNC Machining Service in China is Fundamental?

The selection of a CNC machining service provider in China is a decision that goes beyond mere cost considerations. The right partner brings to the table a combination of technological expertise, industry experience, and a deep understanding of the complexities involved in mold design and manufacturing for food automation machinery. Factors such as the provider’s track record, their investment in the latest CNC technologies, and their ability to offer comprehensive services from design assistance to post-production support are critical. Moreover, the importance of clear communication and the provider’s willingness to collaborate closely with clients cannot be overstated. These elements ensure that the final molds not only meet the technical specifications but also align with the broader production goals and timelines.

Case Study: Successful Partnership with a CNC Machining Service for Mold Production

A leading bakery equipment manufacturer was in the process of developing a new line of automated pastry sheeters. The complexity of the dough molding components required high-precision machining and an intimate understanding of food-grade materials. After an extensive search, they partnered with a CNC machining service in China known for its expertise in the food industry. The collaboration involved several iterations of design optimization, leveraging the service provider’s advanced 5-axis CNC machining capabilities. The project’s success was marked by the seamless integration of the new molds into the pastry sheeters, significantly enhancing the machines’ reliability and the consistency of the pastries produced. This partnership not only met the immediate project needs but also established a framework for future collaboration on innovative food machinery components.

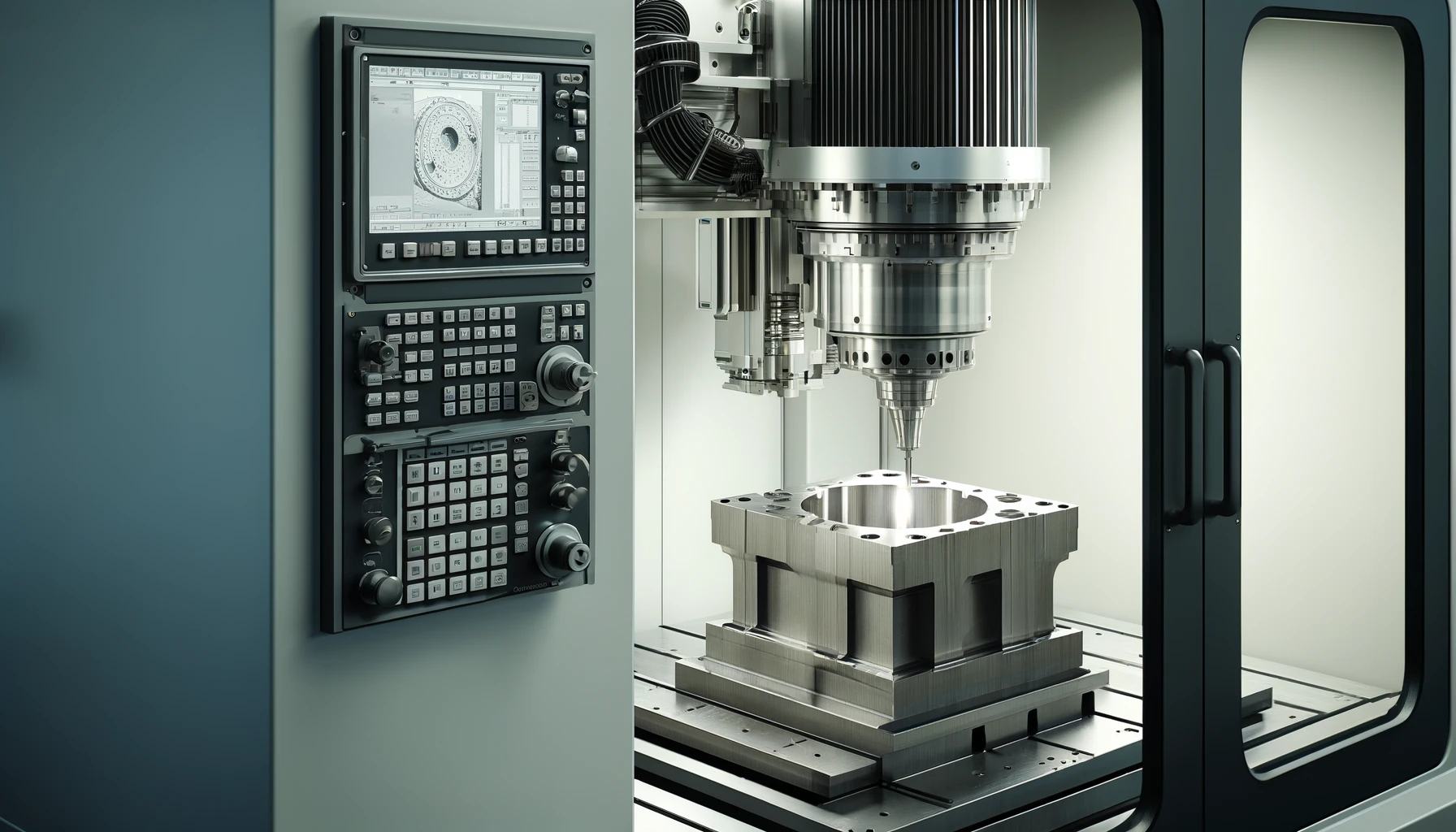

How Does Advanced CNC Technology Propel Mold Manufacturing to New Heights?

The advent of advanced CNC technology has been a game-changer in the field of mold manufacturing, particularly for the intricate requirements of food automation machinery. These technologies offer unparalleled precision, speed, and flexibility, allowing for the production of molds that meet exacting standards. High-speed machining reduces production time without sacrificing quality, while 5-axis milling enables the creation of complex shapes and fine details that were previously impossible or prohibitively expensive. Moreover, adaptive machining technology allows for real-time adjustments during the manufacturing process, accommodating variations in material properties or design specifications.

Data Table: Impact of Advanced CNC Technologies on Mold Manufacturing

| Technology | Precision Level | Efficiency Gain | Cost Impact | Application in Mold Making | Examples |

|---|---|---|---|---|---|

| High-Speed Machining | Very High | Significant | Moderate | Complex Geometries | Rapid prototyping, fine detailing |

| 5-Axis Milling | Exceptional | Moderate | High | Intricate Designs | Undercuts, complex angles |

| Adaptive Machining | High | High | Moderate | Varied Production Runs | Material inconsistencies, design changes |

| Multi-Task Machining | High | Significant | High | Integrated Processes | Drilling, milling, turning in one setup |

| Robotic Automation | Moderate | High | High | Repetitive Tasks | Mold assembly, post-processing |

| Laser Sintering | High | Moderate | High | Prototypes, Small Batches | Complex mold components, lightweight designs |

This table demonstrates how different CNC technologies can be leveraged to enhance the mold manufacturing process, offering a spectrum of benefits from increased precision to greater efficiency and flexibility in production.

Navigating the Challenges of Quality Assurance in Mold Manufacturing

Quality assurance in mold manufacturing is a multifaceted challenge, particularly when dealing with the stringent requirements of food automation machinery. Ensuring that every mold meets the necessary specifications for dimensions, material properties, and surface finish requires a comprehensive approach. This includes advanced metrology equipment for accurate measurements, rigorous testing protocols to simulate real-world use, and certifications that attest to the adherence to industry standards. A robust quality assurance framework not only guarantees the performance of the molds but also contributes to the longevity of the machinery they are a part of.

Case Study: Implementing Stringent Quality Assurance Measures in Mold Production

A manufacturer of automated pizza topping equipment faced recurrent issues with the consistency of their sauce dispensing molds. The variances in mold dimensions were leading to uneven sauce distribution, affecting the quality of the final product. By partnering with a Chinese CNC machining service specializing in precision mold manufacturing, they were able to overhaul their quality assurance processes. The service provider implemented advanced 3D scanning and CMM (Coordinate Measuring Machine) techniques to ensure that each mold met strict dimensional tolerances. Additionally, the molds underwent rigorous functional testing, replicating the high-speed operations of the pizza topping line. This comprehensive approach to quality assurance not only resolved the issues with sauce distribution but also set a new standard for mold production in the company.

What Role Does Communication Play in Custom Mold Projects?

Effective communication stands as a cornerstone in the successful execution of custom mold projects, especially when navigating the complexities of food automation machinery. The intricate details required for these molds necessitate a seamless exchange of ideas, feedback, and adjustments between the client and the CNC machining service provider. Regular updates, clear documentation, and open channels for feedback ensure that the project stays aligned with the client’s expectations and the technical requirements. This collaborative approach not only mitigates the risks of misunderstandings but also fosters innovation by combining the client’s industry insights with the technical expertise of the machining service.

Leveraging Cost-Effectiveness Without Compromising on Mold Quality

In the competitive landscape of mold manufacturing for food automation machinery, achieving cost-effectiveness without sacrificing quality is paramount. This delicate balance involves several strategies, including optimizing design for manufacturability, selecting the most suitable materials for both performance and cost, and establishing long-term partnerships with CNC machining services for volume discounts and improved collaboration. Efficient design reduces waste and machining time, material selection can significantly affect both cost and performance, and strong partnerships ensure a mutual understanding of quality and cost objectives.

Data Table: Cost-Effective Strategies for Mold Manufacturing

| Strategy | Cost Savings | Quality Impact | Implementation Complexity | Examples |

|---|---|---|---|---|

| Efficient Design | High | None | Moderate | Minimizing material use, simplifying geometry |

| Material Optimization | Moderate | Low | Low | Selecting alternative, cost-effective materials |

| Long-Term Partnerships | High | Positive | High | Volume discounts, dedicated support |

| Process Automation | High | None | High | Implementing robotic assembly, automated QC |

| Modular Design | Moderate | None | Moderate | Designing molds in interchangeable sections |

| Lean Manufacturing | High | None | High | Reducing waste, streamlining processes |

This table showcases strategies that mold manufacturers can employ to remain cost-effective while still adhering to the high-quality standards required for food automation machinery molds. Each strategy comes with its own set of considerations but, when implemented thoughtfully, can lead to significant savings and efficiency gains.

Future Trends in CNC Machining for Food Automation Machinery Molds

Staying ahead of the curve in terms of technological and industry trends is crucial for manufacturers looking to optimize their mold production for food automation machinery. Emerging trends such as the integration of artificial intelligence (AI) for predictive maintenance and optimization, the adoption of sustainable materials to meet environmental and safety standards, and the shift towards Industry 4.0 practices for smart manufacturing are set to revolutionize the mold manufacturing landscape. These advancements promise not only to enhance the efficiency and precision of mold production but also to introduce new possibilities for customization and innovation in food automation.

By embracing these trends and continually adapting to the evolving technological landscape, manufacturers can ensure that their mold production processes remain at the cutting edge, capable of meeting the ever-growing demands of the food automation industry.

Other Articles You Might Enjoy

- What Impact Does Choosing China CNC Machining Service Have on the Durability and Reliability of Support Parts in Food Automation Machinery?

Precision Engineering: The Bedrock of Reliable Support Parts In the world of food automation machinery, the reliability and efficiency of the equipment are paramount. At the heart of this reliability…