CNC Machining for New Energy

Home » CNC Machining » Industries » New Energy

Reliable Machined Parts for New Energy Industry

From solar energy to wind energy and gas energy projects, we have a proven track record of delivering high-quality components that meet the stringent requirements of the new energy industry. Our advanced manufacturing capabilities, combined with our commitment to excellence, enable us to produce custom products that are accurate, reliable, and durable.

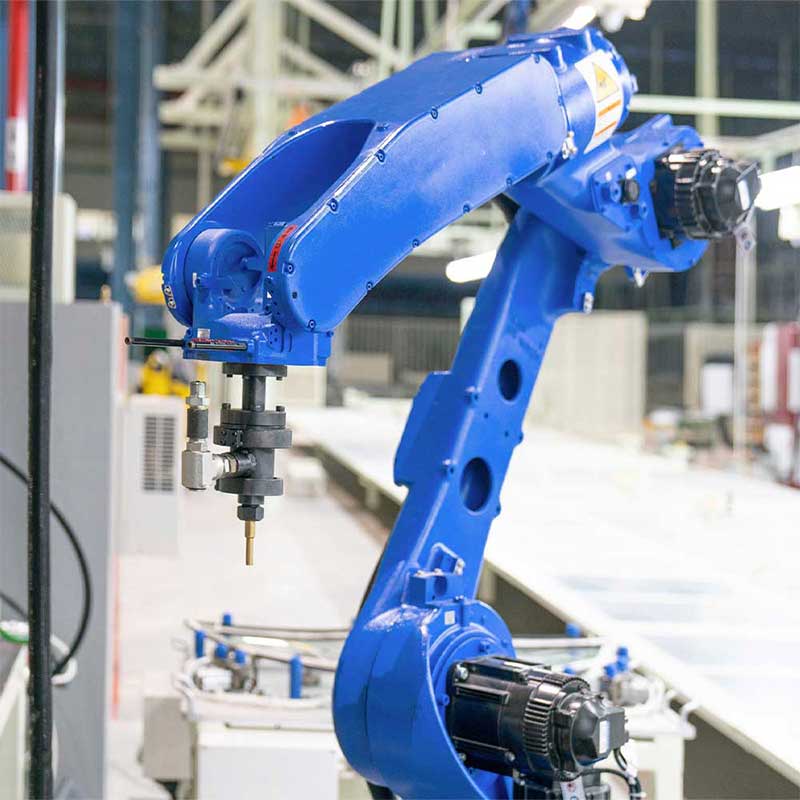

We leverage our expertise in CNC machining to create complex and intricate parts for various applications within the new energy sector. Whether it’s precision components for solar panels, turbine parts for wind energy generation, or specialized components for gas energy systems, our state-of-the-art CNC machines ensure exceptional quality and precision in every product.

Our CNC Machining Services for the New Energy Industry

Let us help power your success in the rapidly evolving world of new energy with our cutting-edge CNC machining services.

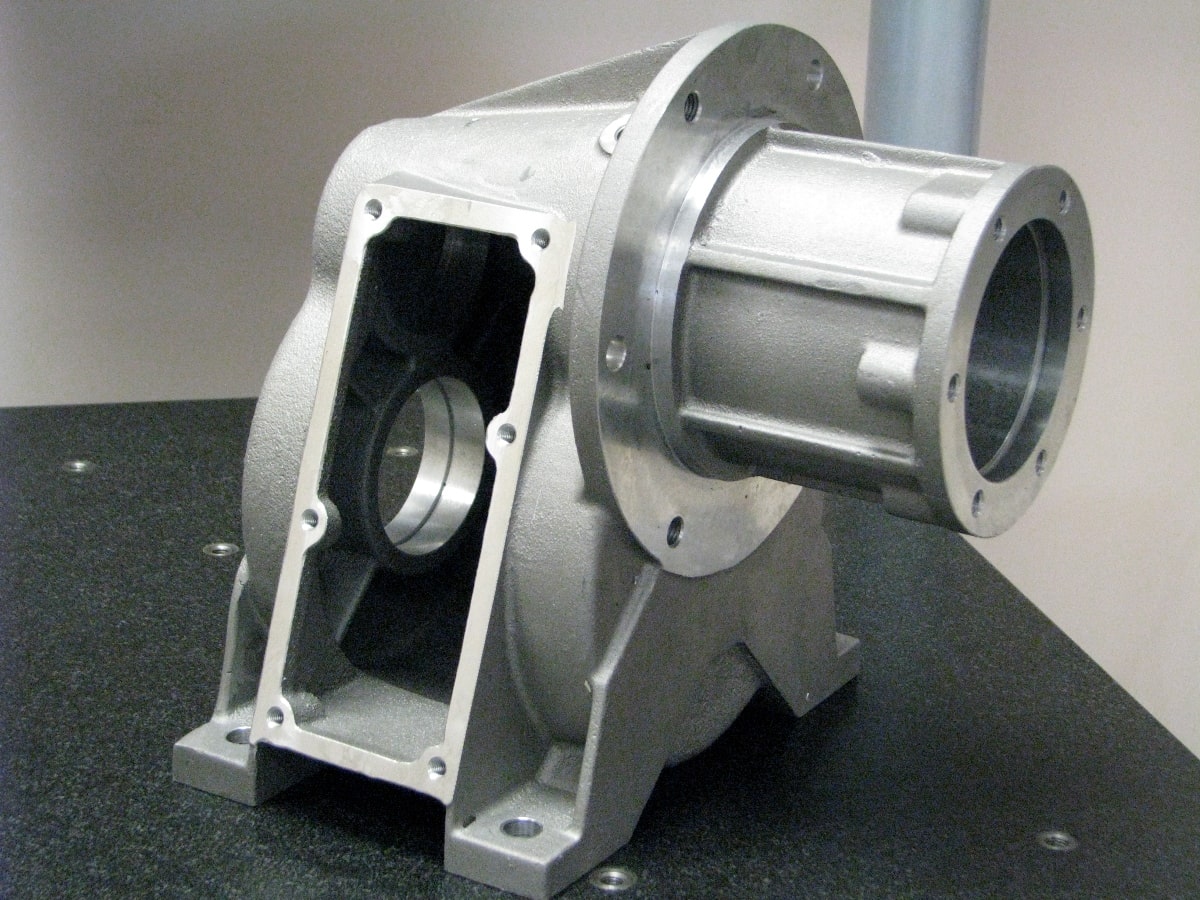

CNC machining ensures precise manufacturing of generator parts, such as housings, rotors, and other critical components, guaranteeing optimal performance and efficiency.

CNC machining allows for the creation of custom jigs and fixtures used in the assembly and production processes of energy equipment, ensuring accurate alignment and improved productivity.

CNC machining delivers high-quality valve components with tight tolerances, enabling precise control and regulation of fluid or gas flow in energy systems.

CNC machining produces intricate turbine components, including blades, shafts, and casings, to meet the demanding requirements of wind, hydro, or gas turbines.

CNC machining ensures the production of durable and precise bushings used in various energy applications to reduce friction and wear between moving parts.

CNC machining offers the production of custom fasteners and connectors that are essential for securely assembling energy equipment and ensuring reliable connections.

CNC machining enables the creation of sockets and specialized tooling required for maintenance and repair of energy systems, ensuring compatibility and ease of use.

CNC machining produces critical hydraulic components like pistons, cylinders, and manifolds with precise tolerances, ensuring efficient energy transfer and control.

CNC machining allows for the production of fit check gauges, which are used to ensure accurate assembly and alignment of energy equipment during the manufacturing process.

Why Choose Want.Net

Trust us as your CNC machining partner for all your custom parts manufacturing needs.

What Our Clients Say

Discover the experiences of our valued clients who trust Want.Net for their CNC machining needs.