Title: Understanding Martensite Structure: Characteristics and Applications in Materials Science

Introduction: Martensite is a unique and highly significant microstructure in the field of materials science, particularly in metallurgy. It is formed in steel and other alloys by a transformation process that drastically changes their mechanical properties. This article delves into the martensite structure, its formation process, characteristics, and its diverse applications across various industries.

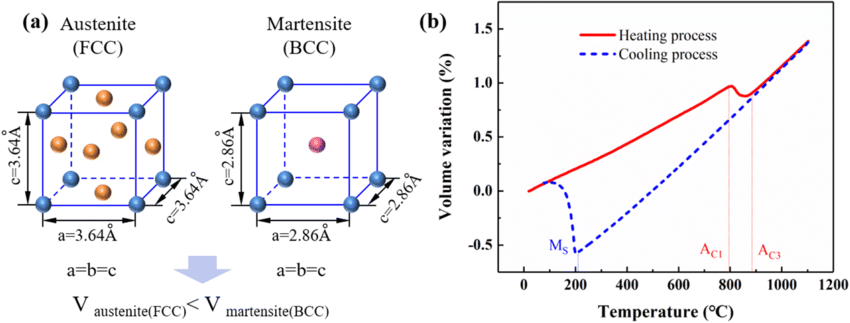

What is Martensite? Martensite is a very hard form of steel crystalline structure, named after the German metallurgist Adolf Martens. It is primarily known for its hardness and is a key feature in many steel alloys. The structure is formed by a rapid cooling process called quenching, which transforms the face-centered cubic lattice of austenite into a body-centered tetragonal lattice of martensite.

Martensite Formation: The Science Behind the Process The formation of martensite is a diffusionless transformation. Unlike other phase changes, atoms shift slightly, but the overall composition remains unchanged. This process, known as a shear transformation, is what gives martensite its distinct properties. It occurs when austenite is cooled quickly enough to prevent the diffusion of atoms, a process typically achieved through quenching.

Characteristics of Martensite Structure

- Hardness and Strength: Martensite is known for its extreme hardness and strength, due to the supersaturation of carbon in the structure.

- Brittleness: While hard and strong, martensitic steel is also quite brittle, making it susceptible to fracture.

- Magnetic Properties: Martensite’s magnetic properties vary based on its carbon content and the presence of other alloying elements.

Applications of Martensite Martensite finds applications in areas where hardness and strength are crucial. Some examples include:

- Cutting tools: Such as knives, shears, and surgical instruments.

- Abrasive wear-resistant components: Used in mining and construction equipment.

- Gears and shafts: In automotive and aerospace industries for high-strength components.

- Armor plates: For military applications due to its impact resistance.

How Martensite Structure is Manipulated? The properties of martensite can be altered through heat treatment processes like tempering. Tempering martensite reduces its brittleness while retaining much of its hardness, making it more suitable for practical applications.

Differences Between Martensite and Other Steel Structures Unlike ferrite or pearlite, martensite has a much higher hardness level. This distinction is crucial in applications that demand durability and wear resistance.

FAQs

- Can martensite be formed in all types of steel? Martensite formation depends on the carbon content and other alloying elements in the steel.

- Is martensite corrosion-resistant? The corrosion resistance of martensite varies based on its composition and treatment.

- How is martensite’s hardness measured? The hardness is typically measured using the Rockwell or Vickers hardness tests.

Conclusion Martensite structure plays a pivotal role in the material properties of steel and other alloys. Its unique combination of hardness and strength, albeit with some brittleness, makes it indispensable in many high-performance applications. Understanding and manipulating this structure is key to exploiting its full potential in various industrial applications.

Reach Out for Expertise in Material Science For further inquiries or detailed consultation on martensite and its applications, contact our team of material science experts. We provide insights and solutions tailored to your specific material needs.

FAQs

- Can martensite be formed in all types of steel? Martensite formation depends on the carbon content and other alloying elements in the steel.

- Is martensite corrosion-resistant? The corrosion resistance of martensite varies based on its composition and treatment.

- How is martensite’s hardness measured? The hardness is typically measured using the Rockwell or Vickers hardness tests.

Conclusion Martensite structure plays a pivotal role in the material properties of steel and other alloys. Its unique combination of hardness and strength, albeit with some brittleness, makes it indispensable in many high-performance applications. Understanding and manipulating this structure is key to exploiting its full potential in various industrial applications.

Reach Out for Expertise in Material Science For further inquiries or detailed consultation on martensite and its applications, contact our team of material science experts. We provide insights and solutions tailored to your specific material needs.

Other Articles You Might Enjoy

- Optimizing Wear Resistance in CNC Parts: Compar

Introduction to CNC Parts and Wear Resistance CNC (Computer Numerical Control) parts play a pivotal role in modern manufacturing, enabling the production of complexly designed products with remarkable precision. Generally…

- The Future of On-Demand Manufacturing: Opportunities and Challenges

Introduction to On-Demand Manufacturing On-demand manufacturing has emerged as an essential component of today's market trends. But what exactly does it mean? Essentially, on-demand manufacturing refers to the production of…

- CNC Machining for Wearable Technology: Material Considerations for Comfort and Durability

Introduction to CNC Machining and Wearable Technology CNC (Computer Numerical Control) machining stands as a pivotal manufacturing process, adept at producing precision parts for a myriad of applications, including wearable…