In the world of machining, selecting the right lathe for your projects can be a crucial decision, especially if you’re considering a versatile tool like the Grizzly lathe. This machine is well-known among hobbyists and professionals alike for its reliability, customization options, and compatibility with CNC modifications. But is it really the best fit for your needs?

I remember my initial encounter with a Grizzly lathe—it seemed perfect for my small batch projects, with just the right blend of affordability and performance. As I began exploring CNC conversions and maximizing its efficiency, I found myself appreciating its unique qualities even more. This guide is based on my experience and research, designed to provide you with a comprehensive overview of the Grizzly lathe’s functionality, CNC compatibility, and much more. Let’s dive into the details, and hopefully, by the end, you’ll have a clearer sense of whether Grizzly is the right choice for your CNC machining needs.

Why It’s Suitable for Small Batch and Custom Machining

The Grizzly lathe has become a popular choice for machinists who require a balance of performance and cost-effectiveness. This section explores the reasons why this machine is well-suited for small batch and custom machining, making it an attractive option for both beginners and experienced operators.

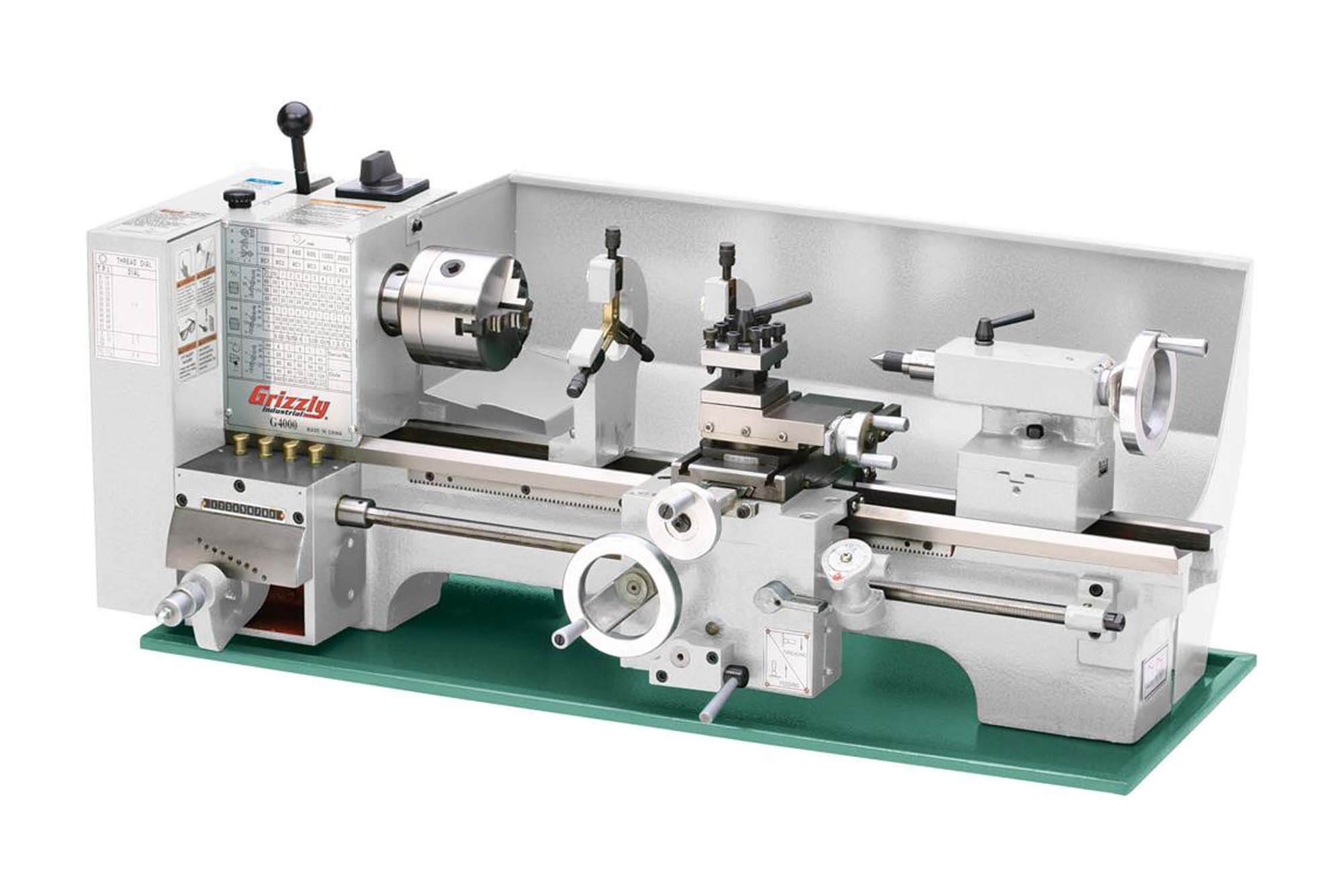

1.1 Overview of Grizzly Lathe

Grizzly lathes are manufactured by Grizzly Industrial, a company renowned for producing affordable yet high-quality machinery. Grizzly offers a range of lathe models, each tailored to specific user needs. Here are some key models:

| Model | Spindle Bore | Swing Over Bed | Motor Power | Price Range |

|---|---|---|---|---|

| G4003 | 1.5″ | 12″ | 2 HP | $2,500 – $3,000 |

| G0602 | 1″ | 10″ | 1 HP | $1,000 – $1,500 |

| G0765 | 0.78″ | 7″ | 0.75 HP | $700 – $1,000 |

| G0776 | 1.55″ | 13.5″ | 2 HP | $3,000 – $3,500 |

| G4000 | 0.79″ | 9″ | 0.75 HP | $1,200 – $1,500 |

| G0709 | 1.38″ | 14″ | 3 HP | $5,000 – $6,000 |

Each of these models offers unique specifications, making it easier to select one that matches your requirements. Generally, Grizzly lathes are geared toward users who need flexibility without the expense associated with industrial-scale machinery.

1.2 Key Features of Grizzly Lathe

- Compact Design: Grizzly lathes are often chosen for their relatively compact size, which makes them suitable for smaller workshops and even home garages.

- User-Friendly Controls: The lathe’s controls are designed with beginners in mind, providing an accessible learning curve while still offering versatility for more advanced users.

- Affordability: Compared to many other brands, Grizzly lathes offer a reasonable price point without compromising on quality.

- Customizable Components: Many users appreciate the lathe’s adaptability, especially when it comes to CNC upgrades.

1.3 Typical Machining Scenarios and Industry Applications

Grizzly lathes are commonly used in several applications, including:

- Prototyping: Ideal for creating prototypes due to their precision and adaptability.

- Small-Batch Production: Suitable for producing custom parts in small quantities, where cost-effectiveness is essential.

- Repair and Maintenance: Often used in maintenance workshops for creating replacement parts.

These machines are particularly favored in industries where precision and small-scale customization are valued, such as automotive, aerospace prototyping, and custom tool manufacturing.

Functionality and CNC Compatibility of Grizzly Lathe

Understanding the capabilities of Grizzly lathes and how well they integrate with CNC technology is essential for anyone considering a purchase or upgrade. This section delves into the structural design, functionality, and CNC conversion potential of Grizzly lathes, as well as how they stack up against similar machines.

2.1 Mechanical Structure and CNC Conversion Possibilities

One of the standout qualities of Grizzly lathes is their robust and straightforward mechanical structure, which makes them prime candidates for CNC conversion. Here are some specific aspects of the design that lend themselves to CNC adaptation:

- Rigid Construction: Grizzly lathes are built with high-quality cast iron, providing stability and durability. This rigid construction reduces vibration, which is crucial for precision CNC work.

- Spindle Accuracy: Most Grizzly models come with pre-aligned spindles and high tolerance levels, enabling consistent and accurate rotation speeds. This feature is important for CNC conversions, where precision and repeatability are essential.

- Cross Slide and Compound Rest: The Grizzly lathe’s cross slide and compound rest are sturdy and capable of supporting modifications like motorized lead screws, essential for CNC operation.

2.2 Standard Functions and Expansion Potential

The Grizzly lathe’s standard functions are suitable for a range of tasks, and these can be further expanded with aftermarket parts. Here’s a breakdown of some key functions and the potential for enhancements:

| Feature | Standard Functionality | CNC Conversion Potential |

|---|---|---|

| Spindle Speed Control | Variable speed ranges for versatile cutting | CNC controller can automate speed |

| Tool Post | Manual four-way tool post | Can be upgraded to a quick-change post |

| Lead Screw | Manual threading and feed controls | Replace with motorized control |

| Tailstock | Fixed manual control | Often kept as-is for CNC conversions |

| Motor | Single-phase or three-phase options | Typically upgraded to a servo motor |

With these existing features, many users find that a Grizzly lathe provides an excellent base for customization, with room to add components that make CNC operations smoother and more efficient.

2.3 Comparison with Other Lathes (e.g., Jet, Harbor Freight)

Grizzly lathes are often compared to other entry-level brands like Jet and Harbor Freight. Each brand has its strengths, but Grizzly is generally viewed as providing a solid balance between price and functionality, particularly for users interested in CNC conversions.

| Brand | Price Range | Key Feature | CNC Compatibility |

|---|---|---|---|

| Grizzly | $700 – $6,000 | High-quality construction | Excellent for conversion |

| Jet | $1,000 – $7,500 | Superior finishes and precision | Moderate for conversion |

| Harbor Freight | $600 – $4,000 | Budget-friendly | Limited CNC compatibility |

While Jet lathes tend to offer finer finishing and are built for more intensive professional use, Grizzly remains a top choice for those who prioritize affordability without sacrificing conversion potential. Harbor Freight lathes, on the other hand, are more affordable but may require additional modifications or support to match the CNC adaptability of Grizzly.

2.4 Conclusion of Functionality and Compatibility

From my experience, Grizzly lathes offer a unique mix of robust construction and modularity that suits CNC adaptation well. When considering other brands, Grizzly remains a preferred choice due to its affordability, ease of conversion, and well-rounded features. If you’re exploring CNC for the first time or looking to expand your capabilities affordably, Grizzly offers an ideal starting point.

How to Upgrade Grizzly Lathe to a CNC Lathe

Upgrading a Grizzly lathe to CNC lathe opens up possibilities for precision, automation, and efficiency. For many machinists, the benefits of CNC capabilities make the conversion process worthwhile. In this section, I’ll walk you through the advantages of CNC conversion, essential preparatory steps, and the parts you’ll need.

3.1 Benefits of Conversion: Improved Precision, Efficiency, and Automation

Converting a Grizzly lathe to CNC offers several key advantages:

- Precision: With CNC, you can achieve high precision cuts and complex geometries that are difficult to replicate manually. CNC accuracy reduces error rates, which is crucial for custom and small-batch production.

- Efficiency: CNC technology increases productivity by automating repetitive tasks. This is beneficial if you’re handling multiple parts or need to replicate designs with consistency.

- Automation: A CNC system can run semi-autonomously, allowing you to focus on other tasks, monitor multiple projects, or even run the lathe during off-hours.

For example, I noticed a significant productivity boost after converting my Grizzly lathe to CNC. Tasks that once required constant manual adjustment became streamlined, giving me the freedom to focus on other projects without sacrificing precision.

3.2 Preparation and Considerations Before Converting

Before diving into the conversion process, here are some crucial preparatory steps and considerations:

- Model Compatibility: Ensure your specific Grizzly lathe model is suitable for CNC conversion. Models like the G4003 and G0602 are popular choices for conversion due to their robust structures and adaptable designs.

- Space and Power Requirements: CNC systems often require additional space for components like control boxes, and may need dedicated power sources for higher power demands.

- Budget and Time: CNC conversion involves costs for motors, control boards, software, and other components. It’s also a time-intensive project, so plan accordingly.

- Skill Level: Basic mechanical and electrical knowledge is helpful. Understanding the basics of CNC software operation will also make the transition smoother.

By addressing these points early on, you’ll be better prepared to manage the conversion project successfully.

3.3 Essential Tools, Parts, and Recommendations

To convert a Grizzly lathe to CNC, you’ll need a selection of specific tools and parts. Here’s an overview:

| Part/Tool | Description | Estimated Cost |

|---|---|---|

| Stepper Motors | Provides automated control of the lathe’s axes | $100 – $300 |

| CNC Controller | Controls the motors and processes commands | $150 – $500 |

| Lead Screws | Enables smooth and accurate axis movement | $50 – $150 |

| Mounting Brackets | Secure motors and other components | $20 – $80 |

| Power Supply | Supplies power to motors and controller | $50 – $150 |

| CNC Software | Controls the machine’s operation (e.g., Mach3) | $200 – $300 |

| Limit Switches | Enhances precision and safety by stopping motor travel | $10 – $40 |

These items are essential for a standard conversion, though specific models and additional parts may vary based on your Grizzly lathe model.

3.4 Conversion Kits and DIY Alternatives

For those who prefer a streamlined process, CNC conversion kits are available, often tailored to specific Grizzly lathe models. Conversion kits provide most of the necessary parts and instructions, reducing the need for trial and error. Popular kits include the FlashCut CNC and Automation Technologies packages, which offer user-friendly setups for DIY conversions.

Alternatively, you can source individual parts, allowing you to customize the setup and potentially reduce costs. However, this DIY approach requires more planning and technical knowledge.

3.5 Tips for a Successful CNC Conversion

Here are some practical tips to ensure a smooth CNC conversion process:

- Follow Installation Guidelines: Kits and CNC controllers usually come with specific setup instructions. Adhering closely to these guidelines can prevent costly errors.

- Test Motors Before Final Installation: Testing your motors for proper response before mounting them can save time. Adjusting motor settings while they’re easily accessible will simplify the process.

- Plan for Cooling: CNC motors and controllers generate heat during operation. Make sure your setup has adequate ventilation or a cooling system to avoid overheating.

Step-by-Step Guide to CNC Conversion of Grizzly Lathe

Converting a Grizzly lathe to CNC can be a straightforward process when broken down into manageable steps. In this section, I’ll outline each phase, from preparation to final installation, to help make your CNC conversion as smooth as possible.

4.1 Detailed Steps: From Preparation to Installation

Below is a step-by-step guide that walks you through the conversion process:

- Gather Required Parts and Tools: Make sure you have all necessary parts, including stepper motors, CNC controller, lead screws, mounting brackets, power supply, and any other components needed for your specific model.

- Disassemble Relevant Lathe Parts: Remove parts that will be replaced or modified, such as manual controls on the X and Z axes, as well as any existing lead screws. Make sure to keep these parts organized for reassembly if needed.

- Install Stepper Motors: Attach the stepper motors to the X and Z axes using mounting brackets. Ensure that the motors are securely fixed and aligned for accurate motion.

- Connect Lead Screws: Replace the original lead screws with motor-compatible ones to allow for CNC control. Secure them in place with appropriate bearings to minimize play and ensure stability.

- Attach the CNC Controller: Mount the CNC controller in a suitable location, ideally in an enclosure for protection. Connect the stepper motors to the controller according to the wiring diagram provided by the manufacturer.

- Set Up the Power Supply: Connect the power supply to the controller and motors. Double-check the voltage and power requirements to avoid overloading or damaging components.

- Install Limit Switches: Attach limit switches on both ends of each axis. These switches prevent the motors from overextending, enhancing safety and precision.

- Configure the Software: Install CNC software (e.g., Mach3 or LinuxCNC) on your computer. Configure the software to recognize your controller and motors, setting appropriate values for motor speed, torque, and axis travel limits.

- Test and Calibrate: Before machining, test each axis to ensure smooth motion and calibrate for accuracy. Make small adjustments as needed until the movement aligns with your software commands.

- Final Assembly and Safety Checks: Reassemble any remaining parts and conduct a final safety check. Verify that all connections are secure, that the limit switches function correctly, and that the machine responds accurately to software commands.

4.2 Choosing and Installing CNC Controllers and Motors

The CNC controller and motors are at the heart of your CNC conversion. Here’s a breakdown of options to consider:

| Component | Options | Description |

|---|---|---|

| CNC Controller | Mach3, LinuxCNC | Controls motor functions and machine commands |

| Stepper Motors | NEMA 23, NEMA 34 | Provides precise rotational control |

| Servo Motors | Optional for advanced setups | Offers greater speed and torque than steppers |

| Power Supply | 24V, 36V, or 48V | Provides required voltage and current for motors |

For my own setup, I opted for a NEMA 23 stepper motor and Mach3 CNC controller, a combination that balanced cost with reliable performance. NEMA 34 motors are also popular for larger Grizzly models, providing additional torque for heavy-duty applications.

4.3 Common Issues and Troubleshooting

While conversion is relatively straightforward, some common issues may arise. Here are solutions for a few frequent problems:

- Motor Vibration: If you notice excessive motor vibration, check for loose mounting brackets and adjust motor alignment.

- Inconsistent Axis Movement: This issue is often due to improper lead screw installation. Ensure they’re secure and straight to minimize backlash.

- Software Configuration Errors: If your software doesn’t recognize the controller, verify the wiring and ensure drivers are correctly installed.

4.4 Safety Tips During Conversion

Safety is a priority throughout the conversion process. Keep these tips in mind:

- Power Off: Always disconnect power when installing or adjusting parts to avoid electrical hazards.

- Wear Protective Gear: Use safety glasses and gloves as needed, especially when handling electrical components or sharp tools.

- Follow Manufacturer Guidelines: Carefully follow installation instructions provided by motor and controller manufacturers for optimal results.

Real-World Examples: User Experiences with Grizzly Lathe

For many machinists, the Grizzly lathe offers a flexible and affordable solution that meets the demands of both hobbyists and small business owners. In this section, I’ll share a few real-world examples of how users have successfully integrated Grizzly lathes into their projects, including CNC conversions, along with the challenges they encountered and how they addressed them.

5.1 Grizzly Lathe Applications Across Different Industries

Grizzly lathes are used in a variety of settings, from automotive shops to educational institutions. Here are some examples of how different industries use these machines:

| Industry | Application | Grizzly Model |

|---|---|---|

| Automotive | Custom engine part prototyping | G0602 |

| Aerospace | Prototype fittings and small parts production | G4003 |

| Education | Training students on basic machining principles | G0765 |

| Jewelry Making | Crafting and resizing metal pieces | G0776 |

| DIY/Home Workshop | Hobbyist projects like tools and custom parts | G0709 |

These examples illustrate the versatility of Grizzly lathes, which cater to a range of applications with their solid construction and customization options.

5.2 User Feedback on CNC Conversion and Usage

Many users report that converting their Grizzly lathes to CNC has been transformative, both in terms of productivity and project capabilities. Here are some insights based on real user experiences:

- Precision and Efficiency Gains: One user shared that after converting their G4003 to CNC, they were able to produce small-batch components for an automotive project with far greater precision than before. CNC allowed for complex cuts and repeatability, saving hours of manual labor.

- Challenges in Conversion: Another user noted that while the conversion process was mostly smooth, they faced difficulties aligning the lead screws perfectly, resulting in slight backlash initially. By making small adjustments to the motor mounts and recalibrating the system, they were able to resolve the issue.

- Cost-Effectiveness for Small Businesses: A small jewelry-making business owner highlighted how their CNC-converted Grizzly lathe enabled them to efficiently create custom designs in-house. This saved them the cost of outsourcing, offering an affordable solution for producing intricate designs with high precision.

5.3 Project Success Stories and Solutions to Common Challenges

One of the most rewarding aspects of using a CNC-converted Grizzly lathe is the ability to tackle a wide range of projects independently. Below are a few success stories shared by Grizzly lathe users:

- Automotive Prototype Development: An independent automotive engineer converted their Grizzly lathe to CNC to develop custom engine parts. By using CNC capabilities, they were able to refine their prototypes with greater control over measurements and tolerances. The biggest challenge they encountered was learning CNC software, but after some practice, they found the software highly intuitive.

- Educational Use: A vocational school instructor reported that the Grizzly G0765 was an excellent teaching tool for students learning machining. The instructor also noted that the CNC conversion provided students with hands-on experience in both manual and automated machining, giving them valuable skills for future jobs.

- Jewelry and Metalworking: In the world of jewelry making, one small business owner used a CNC-converted Grizzly lathe to craft custom rings and pendants. The lathe allowed for precise cuts and intricate designs that would be challenging by hand. The owner did face a learning curve in understanding motor control settings but resolved this through online tutorials.

5.4 Common Challenges and How Users Overcame Them

Even with its many benefits, users do encounter challenges when working with Grizzly lathes, especially after CNC conversion. Here’s a quick overview of common obstacles and practical solutions:

| Challenge | Solution |

|---|---|

| Motor Alignment Issues | Adjust motor mounts and perform recalibration |

| Software Configuration | Watch tutorials or seek online forums for guidance |

| Lead Screw Backlash | Re-tighten lead screws and install anti-backlash nuts |

| Overheating Motors | Add cooling fans or increase ventilation |

| CNC Learning Curve | Practice with simple projects and gradually progress |

I can personally relate to some of these challenges, particularly the CNC learning curve. In my experience, taking the time to learn the software settings and motor configurations pays off significantly, making it possible to complete projects that would be otherwise unfeasible manually.

Performance and Price Comparison of Grizzly Lathe with Other Brands

When considering a Grizzly lathe, it’s helpful to compare it with other popular brands in the entry-level and mid-tier markets, such as Jet and Harbor Freight. Each brand offers distinct advantages, and understanding how they stack up in terms of performance, price, and CNC compatibility can guide you in making an informed decision.

6.1 Performance Analysis of Major Brands

Grizzly, Jet, and Harbor Freight are three of the most commonly chosen brands by machinists at the hobbyist or small-business level. Below, I’ve compiled a table to compare some essential features:

| Brand | Build Quality | Precision Level | CNC Compatibility | Customer Support |

|---|---|---|---|---|

| Grizzly | High | Moderate-High | Excellent | Good |

| Jet | Very High | High | Moderate | Excellent |

| Harbor Freight | Moderate | Moderate | Limited | Fair |

- Grizzly: Known for high-quality construction at an affordable price, Grizzly lathes offer a sturdy build, making them highly suitable for CNC conversion. The brand provides a good balance between performance and affordability.

- Jet: Jet lathes are praised for their high precision and smooth operation, and they’re often found in professional settings. However, Jet models tend to be pricier, and while they can be converted to CNC, the process may be more complex.

- Harbor Freight: These lathes are popular among beginners for their low cost, but they may require upgrades or modifications for CNC compatibility. While not as robust as Grizzly or Jet, Harbor Freight models are a budget-friendly option for light machining.

6.2 Price and Value Comparison

When comparing price ranges, Grizzly is well-positioned in the market, offering a solid balance between affordability and performance. Here’s a table to illustrate approximate price ranges for each brand:

| Brand | Entry-Level Price | Mid-Tier Price Range | High-End Price Range |

|---|---|---|---|

| Grizzly | $700 – $1,500 | $1,500 – $3,500 | $4,000 – $6,000 |

| Jet | $1,000 – $2,000 | $2,000 – $5,000 | $5,000 – $8,000 |

| Harbor Freight | $600 – $1,200 | $1,200 – $2,500 | $2,500 – $4,000 |

In my own experience, the Grizzly G0602 model offers impressive value within the entry-level price range, delivering a high standard of build quality without the premium price tag. While Jet provides superior precision, the cost may be prohibitive for those starting out or operating on a tight budget.

6.3 Recommendations Based on User Type and Application

Choosing the right lathe largely depends on your specific needs, budget, and application type. Here’s a general guide:

| User Type | Recommended Brand | Rationale |

|---|---|---|

| Hobbyist | Harbor Freight | Affordable and suitable for light tasks |

| Small Business Owner | Grizzly | Reliable, cost-effective, CNC-friendly |

| Precision Machinist | Jet | High accuracy and smooth operation |

| Educational Institution | Grizzly | Durable and adaptable for teaching |

For small business owners and educational users, Grizzly stands out due to its durability and versatility. Meanwhile, precision machinists working with detailed designs might favor Jet despite the higher price, as it offers the accuracy needed for fine work.

6.4 Conclusion of Performance and Price Comparison

Overall, Grizzly provides a robust balance of affordability, quality, and CNC potential, making it ideal for a wide range of users. For those on a limited budget or just starting out, Harbor Freight offers an economical solution. However, if precision is paramount and budget allows, Jet may be worth considering.

Maintenance and Care Guide for Grizzly Lathe

Proper maintenance and care are essential to ensure the longevity and performance of your Grizzly lathe, especially after a CNC conversion. Routine checks and timely adjustments not only prevent breakdowns but also keep the machine operating at its best. Here’s a comprehensive guide to maintaining your Grizzly lathe.

7.1 Routine Maintenance Steps and Tools Needed

Regular maintenance tasks help keep your lathe running smoothly and minimize the need for costly repairs. Here are some routine maintenance steps to follow:

| Task | Frequency | Tools Required | Description |

|---|---|---|---|

| Clean the Lathe | After each use | Soft cloth, brush | Remove chips and dust from all surfaces |

| Lubricate Lead Screws | Weekly | Lubricant, grease gun | Apply lubrication to prevent wear on lead screws |

| Check Belt Tension | Monthly | Wrench | Ensure drive belts are taut and not worn |

| Inspect Electrical Connections | Monthly | Screwdriver | Check for loose wires, especially on CNC components |

| Calibrate CNC Motors | Quarterly | CNC software, caliper | Recalibrate motor settings for precise movement |

| Replace Worn Parts | As needed | Various tools | Replace any visibly worn or damaged parts |

These maintenance tasks are straightforward but make a significant difference. Keeping a maintenance log can also help you track when each task was last completed, ensuring consistency over time.

7.2 Tips for Addressing Common Issues

Even with proper maintenance, issues can arise. Here are some common problems Grizzly lathe users encounter and tips for addressing them:

- Noise or Vibration: Excessive noise often indicates loose parts or misalignment. Check the mounting screws and motor alignment.

- Inconsistent Cuts: Inconsistent cuts can result from worn-out cutting tools or improper tool post alignment. Regularly inspect and sharpen or replace cutting tools as needed.

- Backlash on CNC Axis: Over time, backlash may develop in the CNC lead screws, affecting accuracy. Installing anti-backlash nuts or adjusting the lead screw tension can help.

7.3 Best Practices for Extending the Lifespan of the Equipment

To maximize the lifespan of your Grizzly lathe, consider these best practices:

- Keep It Clean: Dust and debris can accumulate and interfere with moving parts. After each use, clean the machine to avoid buildup.

- Use Quality Lubricants: Lubricating moving parts is essential, but using high-quality lubricants specifically designed for metalworking machinery will enhance protection and performance.

- Avoid Overloading: Stay within the machine’s recommended load limits. Overloading can strain the motor and other components, leading to accelerated wear.

- Regular Calibration: After a CNC conversion, periodic recalibration ensures the motors and control systems maintain precise operation, especially if the machine is used frequently.

- Check Electrical Components: For CNC users, inspecting wiring and electrical connections regularly can prevent sudden failures. Loose or frayed wires can lead to malfunctions or even damage the controller.

In my experience, taking the time to perform these routine checks makes a huge difference in the machine’s reliability and precision. A Grizzly lathe can last for years with consistent maintenance, even under moderate to heavy use.

7.4 Summary of Maintenance Essentials

To sum up, keeping your Grizzly lathe in good working order doesn’t require complex procedures. A few regular checks and adjustments can prevent major issues, maintain accuracy, and extend the machine’s service life. If you’re consistent, the rewards will be evident in the machine’s performance over time.

Post-Conversion CNC Tips for Maximizing Grizzly Lathe Efficiency

Once your Grizzly lathe has been successfully converted to CNC, there are several strategies you can employ to optimize its efficiency and ensure it operates smoothly. Maximizing efficiency not only saves time but also enhances the quality and precision of your projects. In this section, I’ll share tips to help you get the most out of your CNC-converted Grizzly lathe.

8.1 How to Optimize Grizzly Lathe’s Efficiency in CNC Mode

To improve performance after conversion, consider the following strategies:

- Optimize Cutting Speeds and Feeds: Determine the optimal speed and feed rate for each material you’re working with. Excessive speeds can cause chatter and wear on tools, while overly slow feeds can waste time and reduce efficiency.

- Use Tool Paths Strategically: Set up your CNC software to minimize tool travel distance. By optimizing the tool path, you can reduce machining time and minimize wear on the lead screws and motors.

- Implement Tool Offsets: Use tool offsets to maintain precision and compensate for tool wear. This feature allows the software to adjust for slight variations, ensuring consistent results across multiple parts.

- Reduce Tool Changes: Whenever possible, plan operations that use a single tool to minimize tool changes. For multi-tool projects, set up tool changers or organize tool paths to streamline the process.

8.2 CNC Troubleshooting and Preventative Measures

Operating a CNC machine introduces unique challenges, but being prepared can help you avoid issues. Here are some common problems and preventative measures:

| Issue | Prevention Tips |

|---|---|

| Motor Overheating | Use cooling fans or reduce duty cycles |

| Axis Drift | Regularly check lead screws and calibrate |

| Controller Lag | Ensure software is updated and system requirements are met |

| Electrical Noise Interference | Use shielded cables and ground your controller |

If you experience motor overheating, consider reducing prolonged duty cycles or adding cooling fans. Additionally, grounding your controller and using shielded cables can prevent electrical interference that may disrupt CNC operations.

8.3 Tips for Improving Machining Accuracy and Stability

Accuracy and stability are critical for CNC operations. Here are some methods to enhance both:

- Tighten Gib Screws: Adjust the gib screws on each axis to eliminate any play in the slideways. This prevents unwanted movement during machining.

- Minimize Backlash: Install anti-backlash nuts or make adjustments to the lead screws to maintain precise control over the CNC axis. Backlash compensation settings in CNC software can also help.

- Regular Calibration: Periodically calibrate each axis to maintain accuracy, especially after any adjustments or repairs.

- Use Quality Cutting Tools: The quality of your cutting tools directly affects machining accuracy. Invest in high-quality tools for better performance and less frequent replacement.

From my experience, paying attention to these details not only improves the quality of the output but also extends the life of your CNC components. The better you optimize your setup, the more consistent and efficient your results will be.

FAQ

1. What materials can Grizzly Lathe process?

Grizzly lathes can process a wide range of materials, including soft metals like aluminum and brass, as well as harder materials such as steel and stainless steel. Certain models may also handle plastics and other non-metallic materials, making Grizzly a versatile choice for custom machining.

2. What are common issues when converting Grizzly Lathe to CNC?

Some common issues include motor alignment, backlash on lead screws, and software configuration challenges. These can usually be resolved by carefully following setup instructions, regularly recalibrating, and using anti-backlash nuts.

3. What are the costs and considerations for CNC conversion?

The costs for CNC conversion vary based on the parts and tools you choose, typically ranging from $300 to $1,000. Key considerations include selecting compatible motors, a reliable CNC controller, and the right software to match your specific needs.

4. How does Grizzly Lathe compare to other entry-level lathes?

Compared to other entry-level brands like Jet and Harbor Freight, Grizzly provides a good balance of quality, durability, and affordability. Grizzly lathes are particularly popular among those looking for a CNC-compatible option at a reasonable price.

5. How to handle warranty and after-sales support for Grizzly Lathe?

Grizzly offers reliable customer support and a warranty on their products. However, converting the lathe to CNC may void the warranty, so it’s recommended to check with Grizzly or authorized dealers before proceeding with modifications.

6. Which CNC software is compatible with a converted Grizzly Lathe?

Popular CNC software like Mach3, LinuxCNC, and GRBL are compatible with most Grizzly lathe conversions. The specific software you choose depends on your controller and comfort with each program’s features and interface.

7. How to enhance CNC machining accuracy on Grizzly Lathe?

Accuracy can be improved by tightening gib screws, using anti-backlash nuts, and periodically calibrating the machine. Choosing high-quality cutting tools and optimizing tool paths in your CNC software can also contribute to better precision.

8. Is Grizzly Lathe suitable for educational purposes?

Yes, Grizzly lathes are often used in educational settings because they are affordable, durable, and offer a good range of features for students learning machining basics. The simplicity of the controls and compatibility with CNC make it an excellent learning tool.

9. What safety considerations are involved in CNC conversion?

When converting to CNC, always follow safety protocols, such as disconnecting power during installation and using protective enclosures for the controller. It’s also essential to ensure that all electrical connections are secure and that limit switches are properly installed.

10. How to test the stability of CNC functions after conversion?

After conversion, perform a test run using simple designs to ensure the motors and lead screws move accurately. Check for any misalignment or drift and calibrate as necessary. Running a few sample parts at different speeds will help verify stability.

11. Can I use my Grizzly lathe for both manual and CNC operations?

Yes, many users switch between manual and CNC modes, especially if they install a quick-release mechanism for the motors. This flexibility is particularly useful for those who need a balance between automated and hands-on machining.

12. What are the best practices for maintaining a CNC-converted Grizzly Lathe?

Regularly lubricate the lead screws, keep all parts clean, and inspect the motor mounts and electrical connections. Frequent calibration, especially after heavy use, will help maintain accuracy.

13. What is the best Grizzly lathe model for CNC conversion?

Popular models for CNC conversion include the G0602 and G4003, as they have robust designs suitable for motor and controller modifications. The choice depends on your budget, space, and specific machining requirements.

14. Are there any recommended CNC conversion kits for Grizzly lathes?

Yes, several conversion kits are compatible with Grizzly lathes, such as those from FlashCut CNC and Automation Technologies. These kits often come with pre-selected components, reducing guesswork and streamlining the installation process.

15. What types of projects are best suited for a CNC-converted Grizzly Lathe?

A CNC-converted Grizzly lathe is ideal for custom parts, small-batch production, prototyping, and intricate designs that require high precision. It is popular among hobbyists and small business owners for making tools, engine parts, and custom fittings.

Other Articles You Might Enjoy

- What is a Lathe and How is it Used

What is a Lathe and Why is it Important? What is a Lathe? A lathe is one of the oldest and most versatile machine tools used in manufacturing and production…

- The Role of Molybdenum Alloys in CNC Manufacturing: Are They Underutilized?

Introduction: The Definition, Functionality and Importance of CNC Manufacturing CNC (Computer Numerical Control) manufacturing is a critical method used in modern production processes. Defined broadly, it involves using pre-programmed software…

- Ultimate Showdown: CNC Lathe vs. CNC Turning Center – A Comprehensive Analysis

Introduction to CNC Machinery and Core Differences Between CNC Lathes and Turning Centers CNC (Computer Numerical Control) machinery represents the pinnacle of precision engineering, utilizing computerized systems to control machining…

- Sapphire Machining: Can It Meet the Demands of High-Precision Applications?

Introduction to Sapphire Machining Sapphire machining refers to the precise and intricate process of shaping, cutting, and fine-tuning sapphire materials using specialized techniques. The use of this method has garnered…

- Innovative CNC Machining for the Future of Transportation

Introduction: A Brief Overview of CNC Machining and its Role in Manufacturing CNC machining, also known as Computer Numerical Control machining, is a manufacturing process that uses pre-programmed computer software…

- The Role of Precision in CNC Machining: How Tight Tolerances Impact Cost and Quality?

Introduction: Understanding Precision in CNC Machining In manufacturing contexts, precision is epitomized by Computer Numerical Control (CNC) machining. In essence, CNC machining is a process utilized widely within the manufacturing…