Machining with Titanium in Aerospace Applications

The manufacturing process that involves the use of titanium, particularly in aerospace applications, is referred to as machining with titanium. This method has been increasingly adopted due to titanium’s unique properties such as its strong resistance to corrosion, high heat performance, and exceptional strength-to-weight ratio. These characteristics make it a beneficial metal for numerous components within an aircraft, promising enhanced durability and overall lightness.

- Corrosion Resistance: One major attribute of titanium is its innate corrosion resistance which qualifies it as an excellent material choice for parts subjected to harsh atmospheric conditions often encountered during flights.

- High Heat Performance: Titanium’s ability to maintain structural integrity under high temperature makes it ideal for parts like engines or exhaust systems.

- Strength-To-Weight Ratio: Titanium’s outstanding strength-to-weight ratio ensures sturdy yet lightweight parts, cumulatively resulting in more fuel-efficient aircrafts.

Nevertheless, machining with titanium poses challenges because of its hard nature, leading to increased wear on equipment and a need for slower production speeds, thus raising questions about cost-effectiveness. The benefits and drawbacks must be thoroughly evaluated when considering this application.

The Preeminence of Titanium in Aerospace Industry

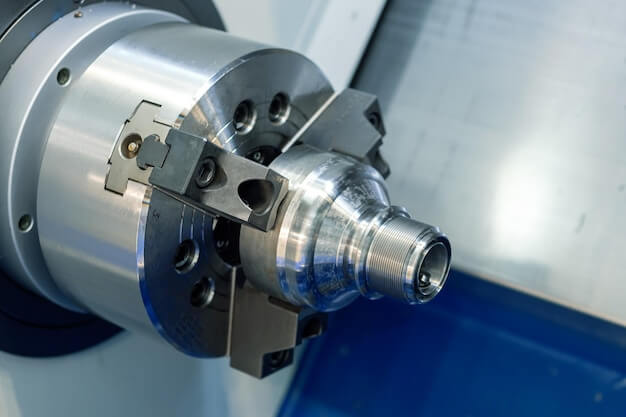

Titanium is a highly favored material in aerospace CNC machining due to its:

- Roughly 30% greater strength and 50% lighter weight compared to steel

- Excellent resistance to high temperatures and corrosion

- Common applications in aerospace, automotive engines, premium marine equipment, and industrial machines

Cost Analysis of Machining with Titanium

The comprehensive cost of machining with titanium for aerospace applications encompasses several aspects such as the initial investment, operating expenses, maintenance, and replacement costs. Beginning with the initial investment, purchasing titanium can be a significant expenditure due to its high market price compared to other metals like aluminum or steel. The machining process itself is an operational cost which accounts for factors like machine running time, energy consumption, and labour.

- Maintenance costs involve periodic inspection, repair, component replacement if necessary, further adding to the overall expense.

- The last cost factor is tied to the longevity of titanium parts. While they are expensive initially, their durability reduces frequent replacement needs, potentially mitigating the long-term cost.

An example demonstrating this balance would be within the aerospace industry where long-lasting, highly resilient parts ultimately prove more cost-effective despite higher upfront costs associated with titanium machining.

Comparing Costs: Traditional Alloys vs. Titanium in Aerospace Industries

The decision between traditional alloys and titanium for aerospace applications involves a comprehensive analysis of costs, accompanied by considering factors such as durability, strength-to-weight ratio, and temperature resistance. On the one hand, conventional alloys like aluminum are less costly up front, easy to machine, and have been reliable substances within the industry for years.

-

Durability: Though these alloys exhibit decent tensile strength, they may succumb quicker than titanium in terms of longer-term durability due to wear and tear and fatigue over time.

-

Strength-to-Weight Ratio: These materials also fall short of titanium when it comes to maintaining maximum strength at lower weights that optimizes fuel efficiency.

-

Temperature Resistance: In addition, while suitable for many aerospace parts, traditional alloys have a lower melting point, reducing their suitability for high-temperature environments compared to titanium.

On the other hand, despite its higher initial cost, titanium stands as a highly durable material with an excellent strength-to-weight ratio, making it ideally suited for light but tough aircraft structures and engine components. Moreover, titanium’s superior resistance to temperature changes, especially higher ones, further cements its place as a favorable option for the long run.

Longevity and Maintenance Aspect of Titanium in Aerospace Applications

In the context of aerospace applications, titanium’s lifespan, durability, and maintenance requirements are vital considerations. One significant advantage that this metal brings is its exceptional longevity; it can outlast many other materials because of its inherent resistance to corrosion and high melting point. For instance, aerospace giant Boeing has frequently utilized titanium for crucial components due to their long life-cycle expectation. Unlike other metals such as aluminium or steel, titanium parts typically require less frequent replacements, reducing both direct costs and potential downtime.

- Life-span: Compared to other materials like aluminum, titanium’s longer lifespan reduces the need for replacements.

- Durability: The robustness of titanium resists wear and tear effectively, minimizing damages caused by harsh aviation conditions.

- Maintenance: Engineered to withstand severe temperatures and corrosive environments, less routine check-ups and fixes are required for these parts overall.

The promising longevity and lower maintenance demand of titanium undeniably contribute to its higher cost, but these enduring characteristics often make it a worthy investment for the aerospace industry.

Value Proposition of Titanium in Aerospace Applications

Despite the considerable initial investment, the use of titanium in aerospace applications offers a compelling value proposition. The long-term benefits often outweigh the upfront costs, as suggested by various research data and case studies. Primarily, the operational savings and enhanced performance provided by titanium parts validate its high cost.

- Durability: Titanium’s exceptional strength-to-weight ratio enables greater fuel efficiency and longevity, reducing replacement and maintenance costs over time.

- Resistance: Its capacity to withstand extreme temperatures and resist corrosion makes titanium an optimal choice for aircraft parts – greatly increasing flight safety and decreasing potential repairs or replacements tied with wear and tear.

- Versatility: Versatile in nature, it forms alloys that further enhance these characteristics – making it invaluable to the production of varying aerospace components.

In conclusion, though initially more expensive than alternatives, titanium promises significant long-term financial and operational advantages in aerospace engineering due to its unique properties and versatility.

Environmental Impact of Machining with Titanium versus Conventional Alloys

The environmental footprint associated with machining titanium in comparison to conventional alloys used extensively in the aerospace industry is a significant factor worth scrutinizing. The extraction and processing stage of titanium from its ore, rutile, demands an exceptional amount of energy, usually sourced from fossil fuels, leading to substantial CO2 emissions. In contrast, traditional alloys typically require less energy for extraction and processing since public resources like aluminum or iron form the bulk of their composition. This stark variance directly translates into more carbon emissions when using titanium instead of traditional alloys.

- Energy Consumption: On average, the production of one ton of titanium necessitates around 42,000 kWh of electricity while producing the same quantity of steel requires just 3,200 kWh, making titanium’s energy requirements considerably higher.

- Emissions: The high-energy consumption during titanium production often results in higher greenhouse gas emissions as compared to standard alloys, potentially exacerbating global warming concerns.

- Recyclability: Recovering and reusing titanium is more arduous than recycling common alloy materials like aluminium or steel, further amplifying its environmental burden.

In conclusion, from an environmental standpoint, the preference for traditional alloys over titanium becomes significantly apparent given these technical principles.

Concluding Thoughts on the Worth of Titanium in Aerospace Applications

In conclusion, comparing costs with the unique properties that titanium offers for aerospace applications hints at substantial benefits. Its distinctive strength-to-weight ratio, coupled with excellent corrosion resistance and superior tolerance to temperature fluctuation, makes titanium an unbeatable choice when it comes to manufacturing aircraft components despite its relatively high initial cost.

- Titanium’s extreme durability guarantees long-term use and reduces repair and replacement expenses over time, thereby balancing out the higher upfront investment.

- It also significantly enhances safety margins due to its resilience, directly increasing reliability under various harsh flight conditions.

- The tremendous reduction in fuel consumption resulting from the lightweight nature of titanium adds another layer of savings financially as well as ecologically. This aspect gains importance considering the growing emphasis on green technology deduction in carbon footprint within modern aviation industry.

Hence, while incorporating titanium in plane construction certainly raises production expenditure initially, considering the extensive advantages it brings about seems like a price worth paying in the greater perspective of aerospace applications.

Other Articles You Might Enjoy

- CNC Machining for Aerospace: Titanium Alloys vs. Aluminum - Performance and Cost Analysis

CNC Machining in the Aerospace Industry: An Introduction and Importance of Material Selection CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software directs the movement of…

- CNC Machining for Aerospace Applications: Titanium vs. Aluminum Alloys

CNC Machining in Aerospace: An Introduction and Overview Computer Numerical Control (CNC) machining is a manufacturing process that utilizes software-directed machines to fabricate complex parts with high accuracy and repeatability.…

- CNC Machining for Aerospace: Titanium vs. Aluminum Alloys Comparison

CNC Machining in Aerospace Industry: Material Choice Significance CNC machining, an abbreviation for Computer Numerical Control machining, is a process utilized extensively in the aerospace sector. The technology relies on…