Introduction

In the world of manufacturing, particularly in CNC machining, the choice of material plays a pivotal role in the performance, cost, and durability of parts. Among the most commonly discussed materials are titanium and aluminum. This article delves into the question: Is titanium lighter than aluminum? While the answer might seem straightforward, understanding the distinct characteristics and CNC machining challenges associated with each material is essential for buyers seeking custom parts.

Material Properties Overview

Both titanium and aluminum possess unique attributes that make them suitable for various applications. Below is a comparative overview of their essential properties.

| Property | Titanium | Aluminum |

|---|---|---|

| Density (g/cm³) | 4.51 | 2.70 |

| Tensile Strength (MPa) | 900 | 200 |

| Yield Strength (MPa) | 800 | 90 |

| Melting Point (°C) | 1668 | 660 |

| Corrosion Resistance | Excellent | Good |

| Fatigue Strength | High | Moderate |

From this table, it is clear that while aluminum is lighter in terms of density, titanium offers a superior strength-to-weight ratio, making it invaluable in high-performance applications.

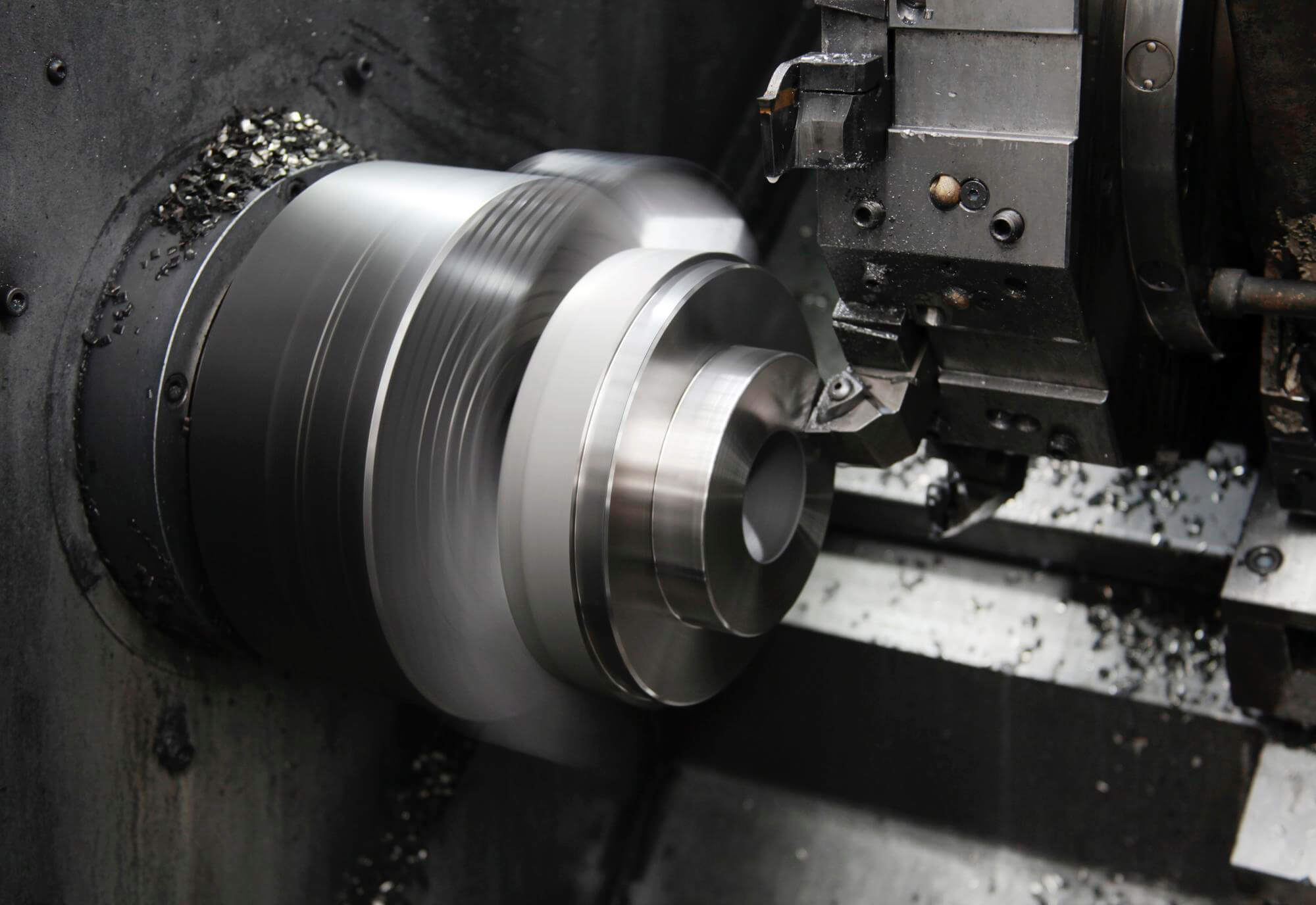

CNC Machining Considerations

When selecting materials for CNC machining, several factors must be considered, including the machinability of each metal, tooling costs, surface finish, and thermal properties.

- Machinability:

- Aluminum: Generally easier to machine due to its lower hardness. It allows for faster cutting speeds and requires less tool wear, leading to lower overall machining costs.

- Titanium: More challenging to machine because of its toughness and tendency to work-harden. It requires slower cutting speeds, increased tool pressure, and often results in more rapid tool wear. Specialized tooling, such as carbide or ceramic inserts, is often necessary.

- Tooling Costs:

- Aluminum: Tooling costs are typically lower as standard tooling can be used, and tool life is longer due to less wear.

- Titanium: Higher tooling costs arise from the need for specialized tools and increased wear rates, leading to more frequent tool changes.

- Surface Finish:

- Aluminum: Can achieve good surface finishes relatively easily. Common processes like anodizing further enhance its aesthetic appeal.

- Titanium: Achieves excellent surface finishes but requires careful management of cutting parameters to avoid discoloration or surface defects.

- Thermal Properties:

- Aluminum: Has lower thermal conductivity, which can lead to issues like overheating during machining if not properly managed.

- Titanium: Better thermal stability allows it to maintain integrity at higher temperatures, making it suitable for applications in harsh environments.

- Chips and Debris Management:

- Aluminum: Produces short chips, making it easier to manage during machining.

- Titanium: Generates long, stringy chips that can complicate chip removal and increase the risk of fire if not properly managed.

Cost Analysis

Understanding the cost implications of using titanium versus aluminum is critical for buyers, particularly those on a budget.

| Material | Average Cost per kg (USD) | CNC Machining Cost (per hour) |

|---|---|---|

| Titanium | 30 | 100 |

| Aluminum | 2.5 | 60 |

This table underscores the significant price disparity between titanium and aluminum, reinforcing the notion that while titanium may provide superior performance, its higher cost can be a significant factor for many buyers.

Case Studies

Different industries leverage the unique properties of titanium and aluminum. Below are two relevant case studies.

Case Study 1: Aerospace Industry

In the aerospace sector, where weight savings are paramount, titanium is frequently utilized despite its higher cost. For example, the Boeing 787 incorporates titanium for its lightweight, high-strength components that withstand extreme conditions.

Case Study 2: Automotive Industry

The automotive industry predominantly employs aluminum due to its lightweight characteristics, which enhance fuel efficiency. Many car manufacturers are increasingly opting for aluminum parts to reduce vehicle weight, demonstrating the material’s versatility.

Conclusion

In summary, while aluminum is lighter than titanium, the choice between these materials in CNC machining extends beyond just weight considerations. Factors such as strength, machinability, corrosion resistance, and cost are equally critical. Understanding the specific challenges and properties of each material empowers buyers to make informed decisions when sourcing custom parts.

FAQs

- Is titanium always more expensive than aluminum?

Yes, titanium is generally more expensive due to its complex extraction and processing methods. - What are the primary applications of titanium in CNC machining?

Titanium is often used in aerospace, medical devices, and high-performance automotive applications. - Can aluminum and titanium be used interchangeably?

While they can sometimes serve similar roles, their unique properties make them suitable for different applications. - How does corrosion resistance compare between titanium and aluminum?

Titanium has excellent corrosion resistance, making it preferable in harsh environments, while aluminum has good resistance but can corrode under certain conditions. - What is the best machining method for titanium?

High-speed machining with specialized tools is recommended for titanium due to its strength. - Does the choice of material affect the lifespan of the CNC machined part?

Yes, the material directly impacts the part’s durability, strength, and performance in its intended application. - How do the thermal properties of titanium and aluminum compare?

Titanium exhibits better thermal stability than aluminum, making it suitable for high-temperature applications. - What machining techniques are recommended for aluminum?

Techniques such as high-speed milling and turning are commonly used for aluminum due to its favorable machinability. - What are the typical challenges in machining titanium?

Machining titanium presents challenges such as rapid tool wear, long chips, and the need for precise temperature control. - How can buyers determine which material is right for their application?

Buyers should assess the specific performance requirements, environmental conditions, and cost constraints to make an informed decision. - Are there hybrid applications that utilize both materials?

Yes, some applications may use a combination of titanium and aluminum to leverage the strengths of both materials. - What impact do surface finishes have on the performance of titanium and aluminum parts?

Surface finishes can enhance corrosion resistance, aesthetic appeal, and fatigue strength in both materials, affecting overall part performance.

Other Articles You Might Enjoy

- CNC Machining for Aerospace Applications: Titanium vs. Aluminum Alloys

CNC Machining in Aerospace: An Introduction and Overview Computer Numerical Control (CNC) machining is a manufacturing process that utilizes software-directed machines to fabricate complex parts with high accuracy and repeatability.…

- The Advantages of Using LSR (Liquid Silicone Rubber) in CNC Prototyping and Production?

Introduction to LSR in CNC Prototyping and Production The utilization of Liquid Silicone Rubber (LSR) in CNC prototyping and production has been growing exponentially due to its numerous advantages. For…

- The Evolution of Plastics in CNC Machining: From ABS to PEEK?

The Evolution of Plastics in CNC Machining: From ABS to PEEK CNC machining, also known as Computer Numerical Control machining, plays an integral role in contemporary manufacturing processes. It enables…

- CNC Machining for Aerospace: Titanium Alloys vs. Aluminum - Performance and Cost Analysis

CNC Machining in the Aerospace Industry: An Introduction and Importance of Material Selection CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software directs the movement of…

- CNC Machining Materials: Acrylic vs. Polycarbonate for Transparent Components

CNC Machining: An Introduction and the Importance of Material Type Computer Numerical Control (CNC) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and…

- CNC Machining for Aerospace: Titanium vs. Aluminum Alloys Comparison

CNC Machining in Aerospace Industry: Material Choice Significance CNC machining, an abbreviation for Computer Numerical Control machining, is a process utilized extensively in the aerospace sector. The technology relies on…