In CNC turning and boring operations in the world of precision machining, transitioning from shoulders to outer diameters (or vice versa) often requires corner transitions. Many engineering drawings will specify these transitions, but they don’t always provide exact dimensions. This is where the programmer steps in, typically choosing values between 0.005 to 0.020 inches (0.125 to 0.500 mm). These transitions can be either 45° chamfers or 90° radii, usually small in size. When the drawing specifies the transition size, the programmer can use it directly. These transitions serve three main practical purposes:

- Functionality: Enhancing strength, ease of assembly, and providing some clearance.

- Safety: Sharp corners can be dangerous.

- Aesthetics: The finished part looks better.

In lathe operations, corner transitions are mainly used between shoulders and adjacent outer diameters, such as on a shaft with 90° cuts. Calculating the start and end points is not difficult but can be time-consuming, especially for parts with multiple different diameters.

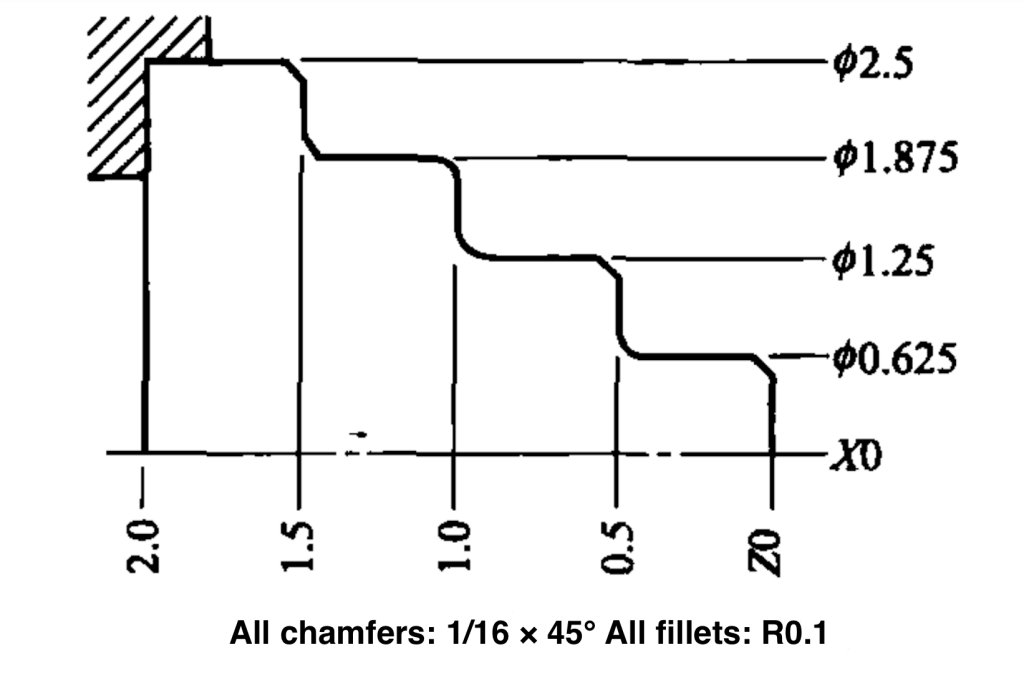

Let’s dive into an example with the workpiece shown in Figure 1. This piece has multiple corners, making it beneficial to use automatic corner transition programming. However, not all corners in the figure can use this method.

Figure 1:

Manual Calculation vs. Automatic Corner Transitions

Manual calculation involves determining each transition point by hand, resulting in a lengthy program. Here’s an example of such a program (03404):

N51 T0100

N52 G96 S450 M03

N53 G00 G42 X0.3 Z0.1 T0101 M08

N54 G01 X0.625 Z-0.0625 F0.003

N55 Z-0.4

N56 G02 X0.825 Z-0.5 R0.1

N57 G01 X1.125

N58 X1.25 Z-0.5625

N59 Z-0.9

N60 G02 X1.45 Z-1.0 R0.1

N61 G01 X1.675

N62 G03 X1.875 Z-1.1 R0.1

N63 G01 Z-1.4375

N64 X2.0 Z-1.5

N65 X2.375

N66 X2.5 Z-1.5875

N67 U0.2

N68 G00 G40 X10.0 Z5.0 T0100

N69 M01This program only covers finishing, starting from a selected safe distance (X0.3). Each corner transition point requires careful calculation. The key challenge is to avoid common errors like forgetting to double the X-axis values, which represent diameters.

In contrast, automatic corner transition programming simplifies this process. Using specific vectors (I, K for chamfers; R for radii), the control system automatically adjusts the toolpath length, saving time and reducing errors.

Programming Automatic Chamfers and Radii

For automatic chamfers and radii, Fanuc control systems provide two primary methods:

- 45° Chamfer: Using I and K vectors.

- 90° Radius: Using R vectors.

Automatic Chamfer (45°)

In G01 mode, the I and K vectors represent the direction and amount of the chamfer. Here’s an example program using automatic chamfers and radii (03405):

03405 (Using Automatic Corner Transitions)

N51 T0100

N52 G96 S450 M03

N53 G00 G42 X0.3 Z0.1 T0101 M08

N54 G01 X0.625 Z-0.0625 F0.003

N55 Z-0.5 R0.1

N56 X1.25 K-0.0625

N57 Z-1.0 R0.1

N58 X1.875 R-0.1

N59 Z-1.5 I0.0625

N60 X2.375

N61 X2.5 Z-1.5875

N62 U0.2

N63 G00 G40 X10.0 Z5.0 T0100

N64 M01Compared to manual calculation, this method shortens the program and eliminates the need for manual transition point calculations. It makes program development quicker and easier, especially when dimensions need to be changed. Simply updating the vector values adjusts the transition sizes without recalculating everything.

Summary

Mastering automatic corner transitions in precision machining not only streamlines programming but also enhances the efficiency and accuracy of the machining process. By utilizing automatic chamfers and radii, programmers can reduce errors, save time, and ensure the final product meets design specifications with a high degree of precision.

Other Articles You Might Enjoy

- Mastering Machining Precision: Fun and Practical Insights

Machining precision is crucial in CNC machining. Whether you're crafting high-tech gadgets or everyday items, getting every detail right matters. Let's dive into the basics of machining precision, focusing on…

- Mastering Corner Control in CNC Machining Parts

CNC machining is all about precision and efficiency, especially when it comes to navigating sharp corners and changing directions. When machining complex contours, the feed rate and movement control are…

- Elevating Precision Standards through Chamfer in CNC Machining

1. Introduction: The Pursuit of Unparalleled Precision In the realm of CNC machining, precision is paramount. This section introduces the article by exploring the significance of precision in manufacturing and…

- Precision and Control in Machining

Machining precision is the foundation for ensuring the performance and longevity of mechanical products. During machining, various factors can cause the correct position between the tool and the workpiece to…

- Precision Prowess: Unveiling the Advantages of China CNC Machining

1. Introduction: The Role of Precision in Manufacturing Excellence In this introductory section, we delve into the critical role that precision plays in manufacturing and set the stage for an…

- Revolutionizing CNC Machining for Complex Aerospace Assemblies

Introduction to CNC Machining in Aerospace Assemblies Computer Numerical Control (CNC) machining represents a significant technological development playing a notable role in the creation of complex aerospace assemblies. CNC machining…