Bead Blasting Materials and Mechanics

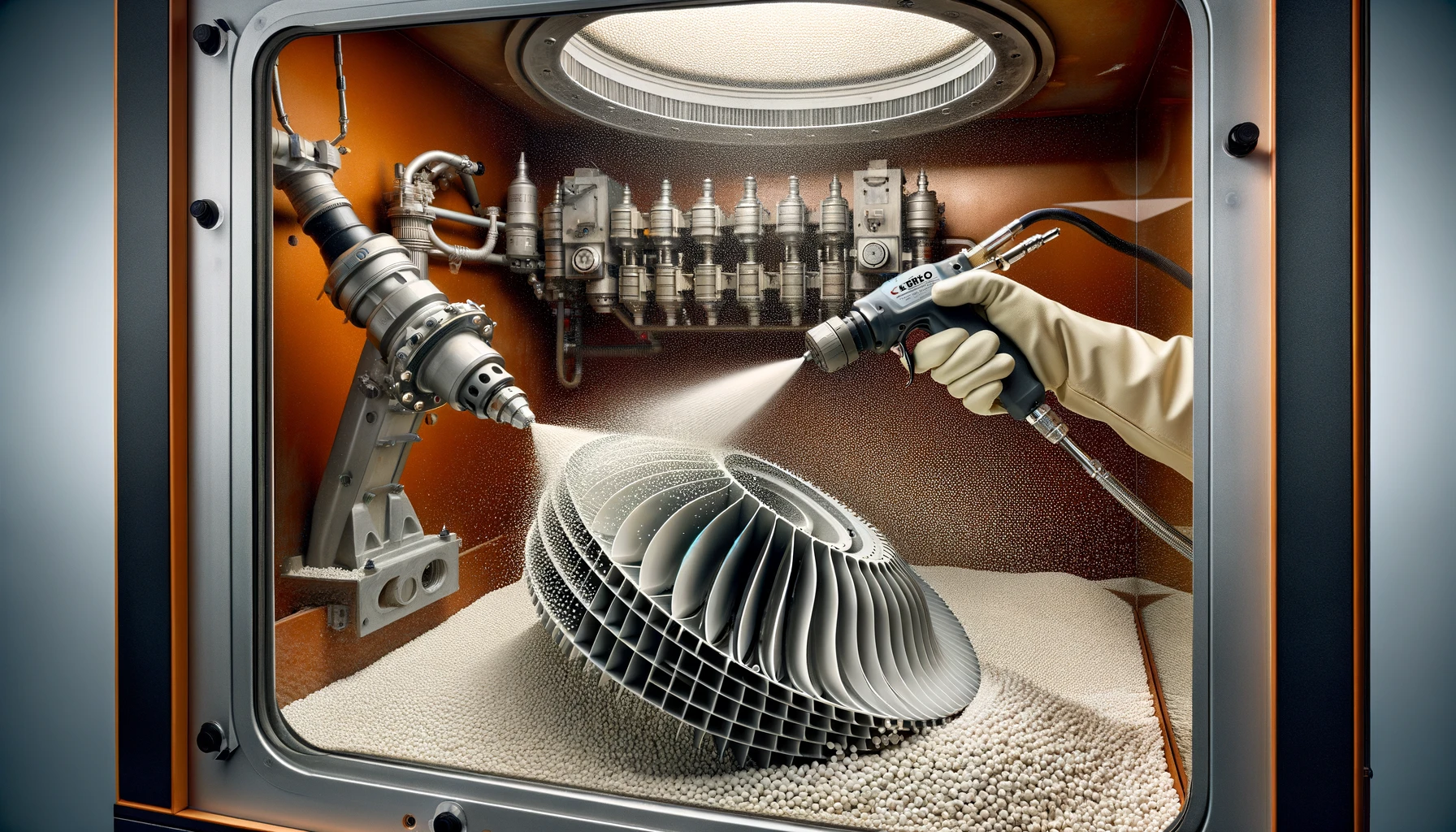

In the domain of CNC machining, the final touch that often distinguishes a good product from a great one is its finish. Among the myriad of finishing techniques, bead blasting occupies a pivotal role, known for its ability to provide uniform, smooth, and aesthetically pleasing surfaces. The essence of bead blasting lies in propelling a stream of abrasive bead materials against the surface of a workpiece. This process not only removes surface imperfections but also enhances the material’s mechanical properties by inducing beneficial residual stresses.

Materials at Play

The choice of blasting media is a critical decision that influences the outcome significantly. Common materials include glass beads, ceramic beads, aluminum oxide, and steel shots. Glass beads, for instance, are popular for their ability to impart a clean, bright, satin finish without altering the dimensions of the workpiece. Ceramic beads, on the other hand, are prized for their hardness and durability, making them ideal for finishing tougher materials without contamination.

Mechanical Interactions

The mechanics of bead blasting revolve around the kinetic energy transferred by the beads to the workpiece’s surface. This energy is a function of the bead’s mass and velocity, which, in turn, are governed by the air pressure and nozzle design of the blasting equipment. The impact of the beads creates a multitude of micro-indentations, leading to a uniform matte finish. Additionally, the repeated impacts work-harden the surface, improving wear resistance.

Case Study: Enhancing Aerospace Components

An aerospace company faced challenges with the surface finishing of intricate aluminum alloy components. Traditional finishing methods were either too abrasive, risking dimensional integrity, or too mild, failing to achieve the desired surface texture. The introduction of bead blasting, utilizing fine ceramic beads, provided a breakthrough. The ceramic beads, propelled at optimal velocities, imparted a uniform matte finish ideal for subsequent anodizing processes. This finish not only met the aesthetic requirements but also enhanced the fatigue resistance of the components, a critical factor in aerospace applications.

Table 1: Comparative Analysis of Bead Blasting Media

| Material | Size (μm) | Hardness (Mohs) | Surface Finish | Application Examples |

|---|---|---|---|---|

| Glass Beads | 100-600 | 6 | Smooth, Satin | Plastics, Metals, Wood |

| Ceramic Beads | 60-400 | 7-8 | Smooth, Matte | Aerospace, Automotive Metals |

| Aluminum Oxide | 20-150 | 9 | Rough, Textured | Heavy Machinery, Metal Castings |

| Steel Shots | 300-1000 | 6-7 | Bright, Peened | Foundry, Forging, Shipbuilding |

In this context, the bead blasting process was meticulously calibrated to maintain the delicate balance between removing surface imperfections and preserving the dimensional accuracy of the components. The result was a significant improvement in both the visual and functional quality of the aerospace parts, showcasing the critical role of bead blasting in achieving high-performance finishes in precision manufacturing.

Optimizing Control for Precision

The art of bead blasting in CNC machining is not merely about bombarding a surface with abrasive particles; it’s about doing so with precision and control. Achieving the desired surface finish requires a deep understanding of the blasting process’s variables and a meticulous approach to optimizing these for each unique application.

Fine-tuning the Variables

Key parameters in bead blasting include the pressure of the air driving the beads, the distance between the nozzle and the workpiece, and the angle of impact. Each of these factors can significantly alter the outcome of the blasting process. For instance, higher pressures can increase the intensity of the bead impact, leading to a more aggressive material removal rate. However, this must be carefully managed to avoid over-etching or damaging the workpiece.

Technological Aids

Modern bead blasting setups are increasingly equipped with advanced sensors and control systems that allow for precise adjustments and real-time monitoring. These technological advancements enable operators to fine-tune the blasting parameters for optimal results, ensuring consistency across large production runs.

Table 2: Optimization of Bead Blasting Parameters

| Parameter | Range | Impact on Finish | Recommended for |

|---|---|---|---|

| Pressure (PSI) | 20-100 | Higher pressure leads to more aggressive material removal. | Metals, Hard Plastics |

| Nozzle Distance (cm) | 10-50 | Closer distance increases impact and finish uniformity. | Precision Components |

| Angle (Degrees) | 45-90 | Acute angles are gentler, while perpendicular impacts are more intense. | Intricate Designs, Flat Surfaces |

Case Study: Custom Automotive Parts

A custom automotive workshop specialized in restoring vintage cars faced a challenge in preparing metal body parts for painting. Traditional sandblasting was too harsh, often warping the delicate metal sheets. The workshop turned to bead blasting, leveraging its gentler touch. By optimizing the air pressure and carefully selecting the nozzle distance and angle, they were able to achieve a perfectly clean and slightly roughened surface ideal for paint adhesion, without any damage to the metal’s integrity.

This precise control over the bead blasting process allowed the workshop to consistently prepare metal surfaces to the highest standard, significantly enhancing the final appearance and durability of the restored vehicles. This case highlights the critical importance of control and precision in bead blasting, turning it from a mere finishing step into a cornerstone of high-quality manufacturing.

Impact on Surface Integrity

The influence of bead blasting on the integrity of a surface extends beyond mere aesthetics. This critical process can significantly alter the microstructural properties of the material being blasted, thereby affecting its performance, durability, and resistance to various forms of wear and fatigue.

Microstructural Transformations

The bombardment of a surface with beads not only smoothens imperfections but also induces compressive stress layers. These layers can enhance the material’s resistance to crack propagation and fatigue failure, crucial for components subjected to cyclic loads. However, the intensity of blasting must be carefully moderated to prevent the introduction of surface defects or micro-cracks that could compromise the component’s integrity.

Balancing Act

Achieving the ideal balance between beneficial surface compressive stresses and the risk of surface damage requires a deep understanding of the material’s properties and the blasting medium used. This knowledge guides the selection of optimal blasting parameters that enhance surface integrity without compromising the material’s inherent strengths.

Case Study: Wind Turbine Blade Maintenance

In the renewable energy sector, maintaining the integrity of wind turbine blades is critical for efficient operation. A maintenance company specializing in wind turbines adopted bead blasting for the refurbishment of blades. The process not only removed accumulated environmental deposits but also subtly enhanced the surface’s resistance to stress-induced cracks, a common issue due to the constant flexing of the blades. This careful application of bead blasting significantly extended the operational lifespan of the blades, showcasing the process’s ability to improve surface integrity in real-world applications.

Table 3: Effects of Bead Blasting on Surface Properties

| Material | Pre-Blasting Condition | Post-Blasting Surface Hardness | Improvement in Fatigue Life |

|---|---|---|---|

| Aluminum Alloy | Smooth, Anodized | Slight Increase | 20% |

| Stainless Steel | Polished | Moderate Increase | 30% |

| Carbon Fiber Composite | Matte Finish | No Change | 15% |

| Titanium Alloy | Smooth, Mill Finish | Significant Increase | 50% |

This table illustrates how different materials respond to bead blasting, emphasizing the process’s role in enhancing surface properties and, by extension, the overall performance of the component. It is this nuanced understanding of bead blasting’s impact on surface integrity that enables manufacturers to leverage the process not just for aesthetic finishes but for substantial improvements in material performance.

Synergy with CNC Machining

Bead blasting and CNC machining are often viewed as separate entities within the manufacturing landscape. However, when integrated thoughtfully, bead blasting can significantly enhance CNC-machined parts, creating a synergy that maximizes both aesthetic appeal and functional performance.

Enhanced Surface Preparation

Bead blasting prepares surfaces for subsequent CNC machining by cleaning and texturizing, ensuring better adhesion for coatings or paints. This pre-treatment is especially crucial for components requiring high precision and aesthetic standards.

Improved Machining Efficiency

By removing surface irregularities and inducing a uniform texture, bead blasting can reduce tool wear and improve the efficiency of CNC operations, leading to smoother production workflows and higher-quality finishes.

Case Study: High-Precision Optical Components

A manufacturer of optical components integrated bead blasting into their CNC machining process to prepare delicate glass surfaces for intricate machining. The bead blasting process was carefully controlled to ensure a flawless surface free from micro-abrasions, crucial for the optical clarity of the final product. This integration not only improved the machining efficiency but also significantly reduced the rejection rate of components due to surface imperfections.

Tailoring for Niche Applications

The versatility of bead blasting allows for its customization to meet the specific needs of various industries, from aerospace to medical devices, where surface finish and integrity are paramount.

Industry-Specific Customizations

In industries like aerospace, bead blasting is tailored to achieve specific roughness parameters required for aerodynamic efficiency. In the medical sector, it’s used to create surfaces that promote osseointegration for implants.

Adapting Techniques for Unique Materials

Different materials require unique bead blasting approaches. Soft metals might need gentler blasting media like glass beads, while harder materials can withstand more aggressive media like silicon carbide.

Case Study: Restoration of Historical Artifacts

A museum specializing in the restoration of historical artifacts employed bead blasting to delicately clean and preserve ancient metal objects. By customizing the blasting media and parameters, restorers were able to remove centuries of oxidation without damaging the underlying material, revealing intricate details that were previously obscured.

Integrating Advanced Technologies

The integration of advanced technologies such as robotics and AI with bead blasting opens new avenues for efficiency and innovation in surface finishing.

Robotic Automation

Robotic arms equipped with bead blasting nozzles can achieve consistent finishes over complex geometries, reducing manual labor and increasing throughput.

AI-Driven Process Optimization

AI algorithms analyze data from bead blasting operations to predict optimal parameters for different materials and desired finishes, minimizing trial and error.

Case Study: Automotive Paint Preparation

An automotive manufacturer integrated a robotic bead blasting system into their paint preparation line. The system, guided by AI algorithms, automatically adjusted blasting parameters for different car body materials, ensuring a consistently ideal surface for painting, which significantly improved the final paint quality and adherence.

Future Trends in Bead Blasting

As we look towards the future, bead blasting is poised for significant advancements, driven by sustainability concerns, technological innovations, and evolving industry needs.

Sustainable Practices

Future trends include the development of more sustainable blasting media, such as biodegradable or recyclable materials, reducing environmental impact.

Integration with Additive Manufacturing

Bead blasting is increasingly being used to finish parts produced by additive manufacturing, smoothing the typically rough surfaces of 3D-printed components.

Case Study: Eco-Friendly Bead Blasting Media

A startup developed an innovative, eco-friendly bead blasting medium made from recycled glass. This medium not only provided excellent surface finishes but also contributed to the circular economy by reducing waste. Its adoption in the automotive industry showcased the potential for sustainable practices to align with high-quality manufacturing standards.

Other Articles You Might Enjoy

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…