In the world of CNC machining, creating precise and complex parts from aluminum alloys is a common yet challenging task. When it comes to thin-walled parts, deformation can be a significant hurdle. This article explores the various factors contributing to deformation and offers practical strategies to mitigate these issues, ensuring the production of high-quality aluminum alloy components.

Understanding Deformation Mechanisms

Deformation during CNC machining of thin-walled aluminum alloy parts can arise from several factors:

- Cutting Forces: When the cutting tool engages the material, it generates forces that can cause the thin-walled sections to deflect. These deflections can lead to inaccuracies in the final part dimensions. Cutting forces stem from the resistance of the material to elastic and plastic deformation and the friction between the tool and the workpiece.

- Thermal Effects: The heat generated during cutting causes localized expansion of the material. As the part cools, uneven cooling can introduce residual stresses and further deformation. This thermal expansion and contraction cycle is particularly problematic for thin-walled parts due to their lower rigidity.

- Residual Stresses: These are stresses that remain in the material after the external forces are removed. Residual stresses can originate from the material’s manufacturing process, such as rolling or forging, and from the machining process itself. When material is removed, the balance of these internal stresses can be disturbed, leading to deformation.

Strategies to Minimize Deformation

To overcome the challenges of deformation in thin-walled aluminum alloy parts, several strategies can be employed:

- Optimized Cutting Parameters: Adjusting cutting speed, feed rate, and depth of cut can help minimize cutting forces and heat generation. Using sharp, high-quality tools and proper lubrication also plays a crucial role in reducing these forces.

- Advanced Fixture Design: Secure and precise fixturing can significantly reduce movement and stabilize the workpiece during machining. Custom fixtures that support the entire workpiece are particularly effective for thin-walled parts.

- Residual Stress Management: Techniques such as stress-relief heat treatments and cryogenic processing can help reduce residual stresses in the material before machining.

- Incremental Machining: Removing material in smaller increments can prevent sudden releases of residual stress and reduce the risk of deformation.

- In-Situ Measurement: Utilizing real-time measurement data to adjust machining paths ensures the final product meets design specifications, compensating for any initial material distortions.

Practical Measures for Thin-Walled Aluminum Alloy Parts

- Pre-Stretched Aluminum Plates: Using pre-stretched aluminum plates instead of mold-forged blanks can significantly reduce initial residual stresses. Pre-stretched plates undergo plastic deformation to alleviate internal stresses, making them more stable during machining.

- High-Speed Machining: High-speed machining technology reduces cutting forces and heat generation, which are critical for minimizing deformation. Increased spindle speeds and feed rates enhance material removal rates while improving surface quality.

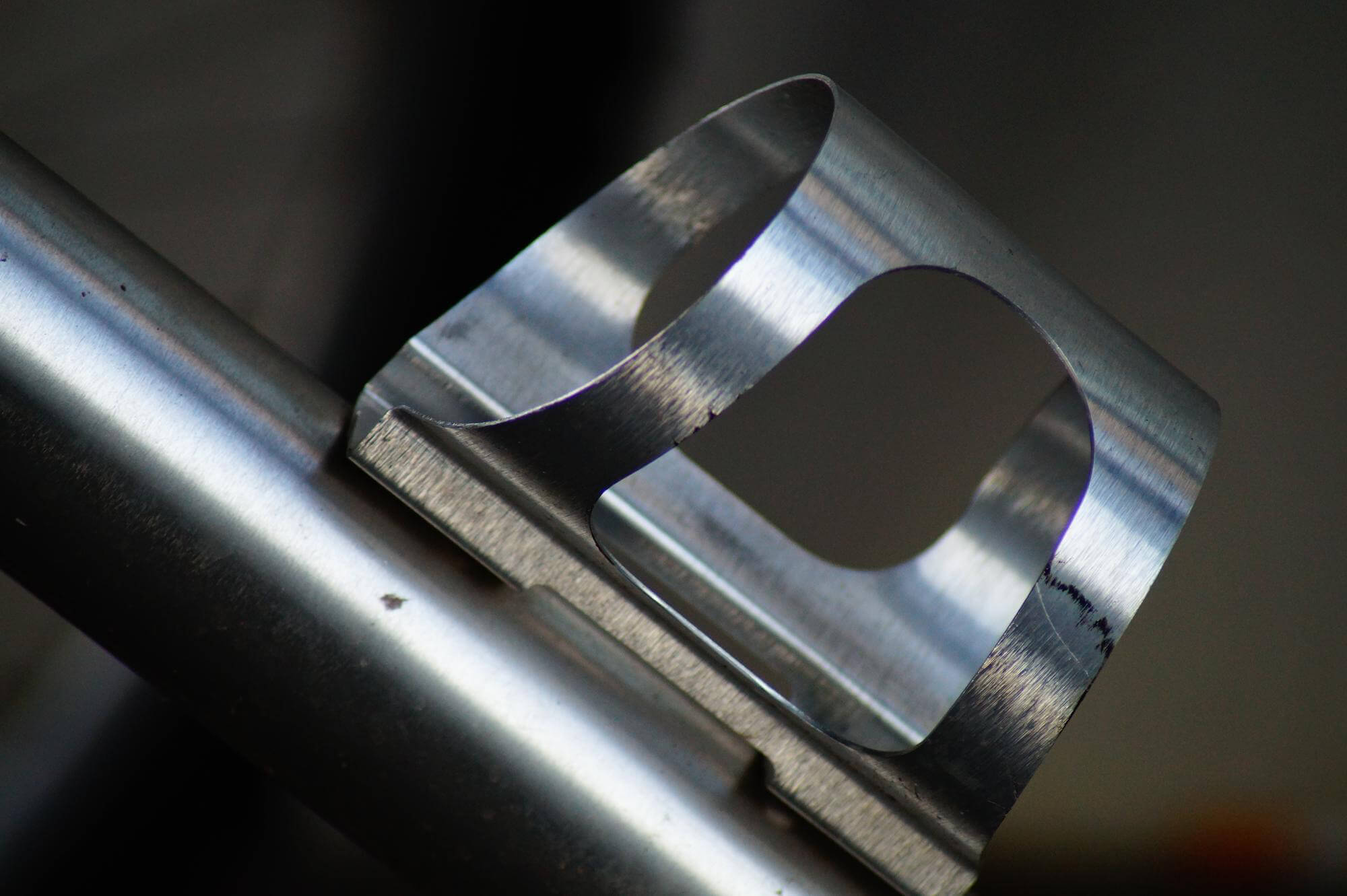

- Parallel Dual-Spindle Machining: This technique employs two spindles with identical end mills rotating in opposite directions. The symmetrical cutting forces applied by the dual spindles counteract each other, minimizing workpiece deformation.

Case Study: Machining a Thin-Walled Aluminum Alloy Frame

Consider the machining of a thin-walled rectangular frame with integral ribs. The part is clamped using a fixture that provides full support. High-speed machining parameters are selected, and the part is incrementally machined to its final dimensions. Throughout the process, in-situ measurements are taken to ensure accuracy. After rough machining, a stress-relief heat treatment is applied, followed by final precision machining. The result is a high-precision, thin-walled frame with minimal deformation.

Data Table:Effects of Cutting Conditions on Deformation

| Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Deformation (mm) |

|---|---|---|---|

| 300 | 0.1 | 2.0 | 3.5 |

| 400 | 0.15 | 1.5 | 2.8 |

| 500 | 0.2 | 1.0 | 2.0 |

| 600 | 0.25 | 0.5 | 1.2 |

By carefully selecting and controlling these parameters, machinists can significantly reduce the deformation in thin-walled parts, ensuring the final product meets the required specifications.

Mastering the machining of thin-walled aluminum alloy parts requires a deep understanding of the deformation mechanisms and the implementation of strategic measures to counteract them. By optimizing cutting parameters, employing advanced fixture designs, managing residual stresses, and utilizing high-speed machining techniques, it is possible to produce high-precision parts with minimal deformation. These practices not only enhance the quality of the parts but also improve overall manufacturing efficiency.

Other Articles You Might Enjoy

- What Are the Challenges of CNC Machining Thin-Walled Stainless Steel Parts?

Understanding Thin-Walled Stainless Steel Parts Thin-walled stainless steel parts are essential in various industries due to their unique properties. These parts combine strength, durability, and corrosion resistance with a lightweight…

- CNC Machining Materials: Acrylic vs. Polycarbonate for Transparent Components

CNC Machining: An Introduction and the Importance of Material Type Computer Numerical Control (CNC) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and…

- Aluminum Grades: Key Characteristics and CNC Machining(Aluminum Grades and Properties Gemma)

As advancements in manufacturing technologies continue to evolve, industries are leveraging more efficient methods like CNC machining for their production processes. One of the commonly used materials in these operations…

- Understanding Aluminum Grades and Properties in CNC Machining (Aluminum Grades and Properties Lynn)

In the field of computer numerical control(CNC) machining, understanding aluminum grades, their properties, as well as how they influence the manufacturing process is vital. Aluminum, owing to its favorable properties…

- Custom Precision CNC Machining in Brass for Medical Devices

Custom Precision CNC Machining in Brass for Medical Devices Computer Numerical Control (CNC) machining is a manufacturing process that utilizes computerized controls to operate and manipulate machine and cutting tools…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…