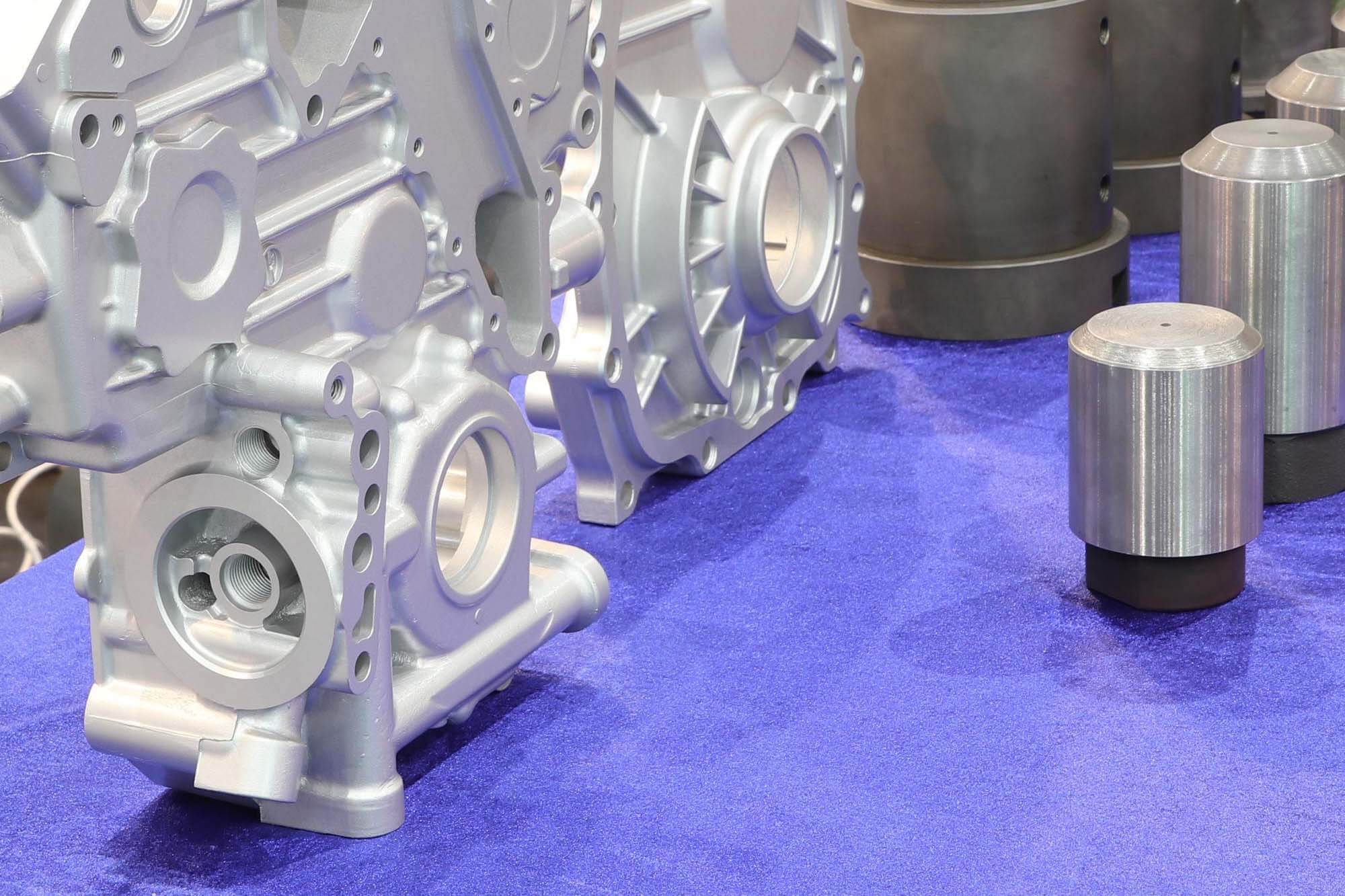

In the world of precision manufacturing, CNC machining plays a crucial role, especially when it comes to tooling die casting with high-strength steels. These materials, known for their durability and resistance to wear, are vital in creating molds that withstand the extreme conditions of die casting processes. This article is tailored for procurement professionals seeking to understand the nuances of CNC machining for tooling die casting with high-strength steels, helping them make informed decisions when choosing suppliers.

Understanding High-Strength Steels

High-strength steels are alloys that combine impressive tensile strength with good toughness, making them ideal for demanding applications such as die casting molds. Typically, these steels are categorized into two main groups:

- High-Strength Steel: Defined by a tensile strength greater than 1200 MPa, these steels are commonly used in applications where strength and ductility are required.

- Ultra-High-Strength Steel: With tensile strengths exceeding 1500 MPa, these steels are engineered for maximum durability and performance under stress.

These steels can further be classified based on their alloy content, such as low-alloy, medium-alloy, and high-alloy steels. Each of these categories has unique properties that influence the CNC machining process.

The Role of High-Strength Steels in Tooling Die Casting

High-strength steels are integral to the manufacturing of die casting molds due to their exceptional mechanical properties. Die casting involves forcing molten metal into a mold cavity under high pressure, and the molds used in this process must withstand significant thermal and mechanical stresses. High-strength steels, with their superior strength and toughness, provide the necessary durability to endure repeated cycles of heating, cooling, and high-pressure metal injection without degrading in performance.

Key Benefits of Using High-Strength Steels in Die Casting Molds:

- Durability: High-strength steels resist wear and tear, extending the life of the die casting molds.

- Thermal Resistance: These steels maintain their mechanical properties even at elevated temperatures, crucial for the high-heat environment of die casting.

- Precision: The stability of high-strength steels ensures that molds retain their shape and accuracy over time, resulting in consistent, high-quality castings.

Subtypes of High-Strength Steels

High-strength steels are often categorized based on the number and type of alloying elements they contain:

- Single-Alloy Steels: These steels contain one predominant alloying element, such as chromium or nickel, providing specific properties like corrosion resistance or enhanced strength.

- Dual-Alloy Steels: Combining two alloying elements, such as chromium-nickel or chromium-molybdenum, these steels offer a balance of toughness and strength, making them suitable for more complex tooling needs.

- Multi-Alloy Steels: Incorporating three or more alloying elements, these steels, such as chromium-nickel-molybdenum or chromium-manganese-silicon steels, are designed for the most demanding applications, offering superior strength and wear resistance.

CNC Machining Challenges with High-Strength Steels

CNC machining of high-strength steels presents unique challenges that must be carefully managed to ensure optimal results:

- Increased Cutting Forces: Due to their high tensile strength, high-strength steels require greater force during cutting, which can increase tool wear and affect surface finish.

- High Cutting Temperatures: The low thermal conductivity of these steels means that heat generated during cutting is not efficiently dissipated, leading to higher temperatures at the cutting edge and potential tool failure.

- Tool Wear: The hardness and toughness of high-strength steels lead to increased tool wear, particularly in the form of abrasive and adhesive wear, necessitating frequent tool changes and careful monitoring of tool condition.

- Chip Formation and Evacuation: High-strength steels tend to produce long, stringy chips that can be difficult to manage, requiring effective chip breaking strategies to prevent damage to the workpiece or tool.

Best Practices in CNC Machining for Tooling Die Casting

To overcome these challenges, the following best practices should be considered:

- Tool Selection: High-performance tool materials such as carbide, ceramic, or CBN (cubic boron nitride) are recommended due to their superior hardness and wear resistance.

- Optimized Cutting Parameters: Careful selection of cutting speeds, feeds, and depths of cut is critical to balancing tool life and machining efficiency. Lower cutting speeds with higher feed rates can help manage heat generation.

- Advanced Cooling Techniques: The use of high-pressure coolant systems or cryogenic cooling can significantly reduce cutting temperatures and extend tool life.

- Precision in Setup: Ensuring rigidity in the machining setup and using high-precision CNC machines can help maintain dimensional accuracy and surface finish quality.

- Surface Treatment Post-Machining: Surface treatments such as nitriding or PVD (physical vapor deposition) coatings can enhance the wear resistance of the machined mold, extending its service life.

Surface Quality Considerations

The surface quality of die-cast molds directly affects the quality of the final cast products. Key factors influencing surface quality during CNC machining include:

- Tool Geometry: The design of the cutting tool, including rake angle, clearance angle, and edge preparation, plays a critical role in achieving a smooth surface finish.

- Feed Rate and Speed: Lower feed rates and optimal spindle speeds can minimize surface roughness by reducing tool deflection and vibration during machining.

- Tool Wear Monitoring: Regular inspection and timely replacement of cutting tools prevent deterioration in surface finish due to worn tools.

Data-Driven Optimization

To optimize CNC machining processes for tooling die casting, data-driven approaches should be adopted:

- Tool Wear Data: Collecting and analyzing tool wear data helps in predicting tool life and scheduling timely tool changes, thereby minimizing downtime.

- Surface Finish Measurements: Regular monitoring of surface roughness using devices like profilometers ensures that machining parameters are adjusted to maintain the desired finish.

- Process Monitoring Systems: Implementing real-time monitoring systems that track temperature, vibration, and tool wear can alert operators to issues before they affect the final product.

Data Tables for Machining Optimization

Below are sample data tables that can be used to track and optimize CNC machining processes:

Table 1: Cutting Parameter Optimization for High-Strength Steels

| Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Tool Life (min) | Surface Roughness (Ra, µm) |

|---|---|---|---|---|

| 30 | 0.2 | 2.0 | 45 | 0.8 |

| 40 | 0.25 | 2.5 | 35 | 0.7 |

| 50 | 0.3 | 3.0 | 25 | 0.6 |

| 60 | 0.35 | 3.5 | 20 | 0.5 |

Table 2: Tool Wear Analysis for High-Strength Steels

| Material Type | Tool Material | Wear Rate (µm/min) | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) |

|---|---|---|---|---|---|

| High-Strength Steel | Carbide | 0.12 | 40 | 0.2 | 2.0 |

| High-Strength Steel | Ceramic | 0.08 | 50 | 0.25 | 2.5 |

| Ultra-High-Strength | Carbide | 0.15 | 30 | 0.2 | 2.0 |

| Ultra-High-Strength | CBN | 0.05 | 60 | 0.3 | 3.0 |

Table 3: Surface Finish Data for Various Machining Conditions

| Machining Condition | Cutting Speed (m/min) | Feed Rate (mm/rev) | Surface Roughness (Ra, µm) | Tool Material |

|---|---|---|---|---|

| Standard Machining | 30 | 0.2 | 1.2 | Carbide |

| Optimized Machining | 50 | 0.3 | 0.6 | Ceramic |

| High-Speed Machining | 60 | 0.35 | 0.5 | CBN |

Supplier Selection Criteria

When selecting a CNC machining supplier for tooling die casting, consider the following criteria:

- Experience with High-Strength Steels: Suppliers should have a proven track record of successfully machining high-strength steels, with case studies or references to back their claims.

- Equipment Capabilities: Ensure the supplier has access to advanced CNC machines capable of handling the demands of high-strength steel machining, including appropriate tooling and cooling systems.

- Quality Control Processes: Suppliers should have stringent quality control processes in place, including regular inspections of surface finish and dimensional accuracy.

- Customization Flexibility: The ability to customize machining parameters and adapt to specific project needs is crucial for achieving optimal results in tooling die casting.

Mastering CNC machining for tooling die casting with high-strength steels requires a deep understanding of material properties, machining challenges, and optimization strategies. By following best practices and leveraging data-driven approaches, manufacturers can produce high-quality molds that meet the rigorous demands of modern die casting processes. For procurement professionals, selecting a supplier with the right expertise and capabilities is key to ensuring project success.

Other Articles You Might Enjoy

- Conquering High-Strength and Ultra-High-Strength Steel in CNC Machining Precision and Techniques Revealed

High-strength and ultra-high-strength steels (HSS and UHSS) are engineering marvels, known for their exceptional combination of strength and toughness. These steels are crucial in industries such as aerospace, automotive, and…

- High-Speed Machining Techniques in CNC Machining Parts: Secrets to Enhanced Efficiency and Quality

High-speed machining (HSM) is an intriguing and evolving field within CNC machining. The term "high-speed" is relative and varies depending on the machining method, workpiece material, and tool material. Defining…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Understanding Bead Blasting in CNC Machining(compressive strength Otto)

Bead blasting is a process appended to Computer Numerical Control (CNC) machining used prominently for surface finishing. It gives the products a clean and appealing look by eliminating tool marks…

- High-Precision CNC Machining for Military Applications

Introduction to High-Precision CNC Machining in Military Applications The technical realm of high-precision Computer Numeric Control (CNC) machining is fast becoming integral to the military sector. This process, which relies…

- Using Acrylic in CNC Machining: Does It Offer Clear Advantages?

Introduction to CNC Machining and Acrylic CNC machining, an abbreviation for Computer Numerical Control, is a process utilized broadly in manufacturing where pre-programmed computer software directs the movement of factory…