CNC (Computer Numerical Control) machining is a popular technique that revolutionizes modern manufacturing. It involves the use of computers to control machine tools including lathes, grinders, routers, and mills, giving us an array of detailed and precision-based products. In line with this technology, we are going to discuss how to remove chrome from metal, focusing on the lightweight metals which are often used in the industry.

Removal of Chrome From Lightweight Metals

There can be several reasons why one might need to remove chrome finish from a metal product. Maybe the chrome has started chipping or you just want to go for a fresh look altogether. Either way, understanding some key methods applicable within CNC machining makes the task easier and more efficient.

One common method of removing chrome from metal employs electrolysis. First, the object is cleaned thoroughly to rid it of dirt and grease then soaked in a solution conducive for electrolysis. The metal part is connected to a power source through a piece of scrap steel (in other cases copper or brass may be used). Then, the current is turned on causing the chrome to dissolve slowly leaving behind clean, bare metal. This process delivers excellent results but caution must always be exercised due to the potentially dangerous chemicals involved.

Another method uses abrasives such as sandpaper, wire brushes, and abrasive blasting equipment. Through friction, these materials chip away the old coating revealing the base metal beneath. Although simple and effective, this so-called mechanical removal tends to consume lots of time when dealing with large surfaces nor complex geometries.

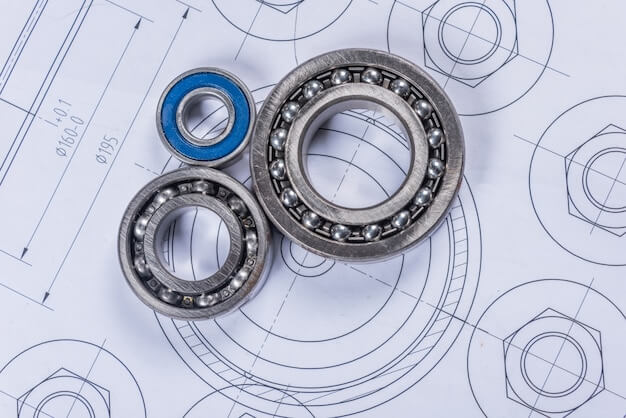

CNC Machines and Lightweight Metals

Lightweight metals like aluminum, titanium, and magnesium alloys are increasingly being used in industries ranging from automotive to aerospace because they allow substantial weight savings without compromising the structural integrity of parts. These types of metals conduct heat incredibly well, making them perfect candidates for various applications in CNC machining.

Using CNC technology, manufacturers can produce complex shapes from lightweight metals with high dimensional accuracy and excellent surface finish. For instance, the aerospace industry often employs 5-axis CNC milling machines to make engine parts out of magnesium alloys because they are lightweight yet have an impressive strength-to-weight ratio.

Producing uniform, defect-free surfaces on aluminum auto body panels also requires high-speed, multifaceted CNC tools that can mill, drill, or cut in a single pass. Thanks to intelligent software systems handling intricate design specifications, these precision engineered products maintain uncompromised quality standards

The digital nature of the CNC process means advanced control over variables such as speed, feed rate, and coordination. Tools can be programmed to execute specific cutting paths, removing material layer by layer, almost like an artist sculpting from a solid block. This makes CNC machining perfect for working with malleable, lighter materials – ensuring cost efficiency and minimized waste production.

In Conclusion

CNC machining provides artisans and manufacturers alike an opportunity to harness the potential of using lightweight metals. While traditional hand methods may prove daunting when tasked with chrome removal, this modern technology brings you precise control over your work. With the right information at hand, anyone can optimally handle industries’ most sought-after materials – lightweight metals while doing away with layers of unwanted chrome.

Always remember to employ safety measure when working around electricity or dealing with potentially hazardous materials during chrome removal processed. Always wear appropriate personal protective equipment and operate in well-ventilated areas. In the vast world of CNC machining, technological advancement ensures limitless possibilities, providing us finely tuned output and efficient operations.

Other Articles You Might Enjoy

- Using CNC Machining to Fabricate Lightweight Metal and Remove Chrome From Metal( cnc machining services china Dana)

CNC (Computer Numerically Controlled) machining is an essential process in the manufacturing domain. With its precision, adaptability, and extensive applications, many industries rely on it for fabricating highly complex parts…

- Efficient CNC Machining of Lightweight Metal and Chrome Removal( cnc machining services china Atwood)

Computer Numerical Control (CNC) machining is a modern manufacturing process used in various industries, frequently dealing with lightweight metals or needing to remove chrome from metal surfaces. This article will…

- Material Flexibility in CNC Machining: Engineering Soft Materials for Complex Parts

Introduction to CNC Machining CNC machining stands as a cornerstone in modern manufacturing, offering precision and repeatability that are unmatched by manual processes. At its core, CNC (Computer Numerical Control)…