Introduction to CNC Machining

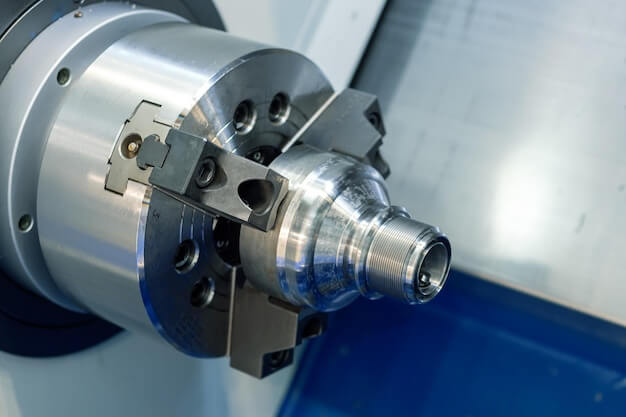

CNC machining stands as a cornerstone in modern manufacturing, offering precision and efficiency in producing parts. At its core, CNC (Computer Numerical Control) machining involves the use of computers to control machine tools, ensuring high accuracy and repeatability. The importance of CNC machining in manufacturing cannot be overstated, as it enables the production of complex shapes that would be difficult or impossible to achieve with manual machining. Material properties play a crucial role in this process, influencing both the machining vibrations and the finishes of the manufactured parts. Different materials, ranging from metals to plastics, each bring unique challenges and considerations to the CNC machining process. For example, harder materials may require slower machining speeds or specific types of cutting tools to achieve the desired finish.

- Efficiency: Enables rapid production of parts with high precision.

- Precision: Achieves complex shapes and fine details not possible manually.

- Material Properties: The hardness, toughness, and thermal properties of materials affect machining dynamics and outcomes.

Understanding Material Properties

Material properties such as hardness, toughness, and ductility play a crucial role in CNC machining, influencing both vibrations and finishes. Hardness measures a material’s resistance to deformation, typically assessed through scales like Rockwell or Brinell. Toughness, on the other hand, indicates a material’s ability to absorb energy before fracturing, which is vital for understanding how a material behaves under stress. Ductility, the ability of a material to deform under tensile stress, is crucial for determining how materials can be shaped without breaking. These properties are measured through standardized tests, providing a quantitative basis for selecting materials for specific machining tasks.

Why do these properties matter in CNC machining? Materials with high hardness levels are more resistant to wear but can induce higher vibrations during machining, affecting the surface finish. Conversely, materials with high ductility may be easier to machine but can lead to deformation if not handled correctly. Understanding these properties allows for the optimization of machining parameters such as cutting speed, feed rate, and tool path, ensuring high-quality finishes and efficient machining processes. For example, machining a highly tough material requires specific strategies to prevent tool breakage and achieve the desired surface quality.

The Impact of Material Properties on CNC Machining Vibrations

Material properties play a significant role in CNC machining vibrations, affecting the overall finish and quality of machined parts. Some key factors to consider include:

- Material Stiffness: The stiffness of the material can influence the level of vibrations during machining, impacting the surface finish and dimensional accuracy of the final product.

- Damping Characteristics: Materials with good damping properties can help absorb vibrations, leading to improved surface finishes and reduced tool wear.

- Resonance Frequency: Understanding the resonance frequency of the material is crucial in minimizing vibrations and achieving high-quality finishes in CNC machining processes.

Material Properties and Surface Finish Quality

The quality of a surface finish in manufactured parts is crucial for their performance, aesthetics, and longevity. It refers to the texture and smoothness of a part’s surface after machining. The properties of the material being machined significantly influence the achievable surface finish. For instance:

- Hardness: Harder materials like metals often require more precise machining tools and conditions to achieve a smooth finish, compared to softer materials.

- Ductility: Materials with high ductility, such as soft plastics, can achieve smoother finishes easily as they allow for finer chips to be removed during the machining process.

An example illustrating this principle is the difference in surface finish when machining soft plastics versus hard metals. Soft plastics, due to their lower hardness and higher ductility, can be machined to a very smooth finish with less effort and simpler tooling. In contrast, hard metals may require specialized cutting tools and conditions (like cooling fluids) to achieve a similar level of finish, due to their higher hardness and lower ductility.

Choosing the Right Material for Your CNC Project

Selecting the appropriate material for a CNC machining project is crucial for balancing machining vibrations and achieving the desired surface finishes. The choice of material directly impacts the quality and cost-effectiveness of the final product. Considerations for selecting materials include:

- Material Properties: Hardness, toughness, and machinability affect both the ease of machining and the level of vibrations experienced. For example, softer materials like aluminum may produce less machining vibrations compared to harder materials like stainless steel.

- Cost and Availability: The cost of materials can vary widely, and availability may affect lead times. It’s important to balance the material costs with the project budget and timeline.

- Intended Use of the Final Product: The application of the final product dictates the material selection. For instance, aerospace components require materials with high strength-to-weight ratios, such as titanium, to ensure performance while minimizing vibrations and achieving smooth finishes.

By carefully considering these factors, manufacturers can select the most suitable material for their CNC projects, optimizing for both performance and cost.

Other Articles You Might Enjoy

- Impact of Material Properties on CNC Machining Speeds and Feeds: Aluminum vs. Copper

Introduction to CNC Machining and its Importance in Manufacturing CNC machining, short for Computer Numerical Control machining, is a foundational technology utilized extensively in the national and international manufacturing sector.…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Understanding Aluminum Grades and Properties in CNC Machining (Aluminum Grades and Properties Lynn)

In the field of computer numerical control(CNC) machining, understanding aluminum grades, their properties, as well as how they influence the manufacturing process is vital. Aluminum, owing to its favorable properties…